Water-cooling condensing machine and water removal method thereof

A condenser and water-cooling technology, applied in refrigerators, compressors, refrigeration components, etc., can solve the problems of high cost, limited moisture absorption of dry filters, etc., and achieve the effect of improving water absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

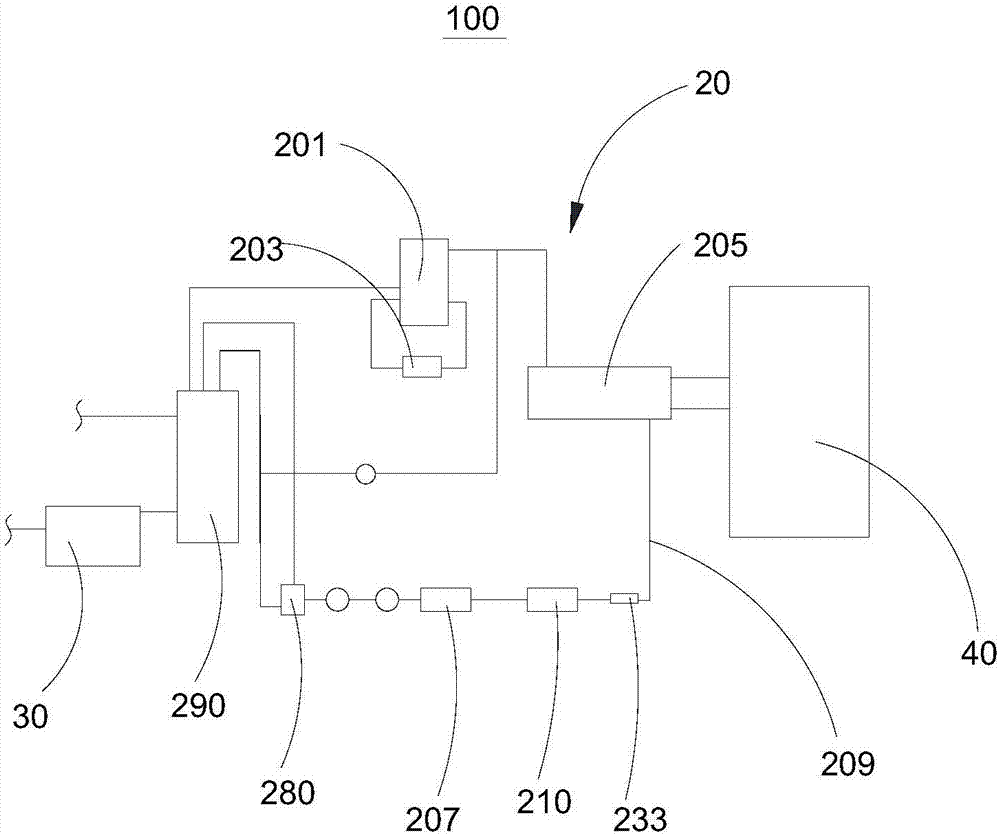

[0025] Please refer to figure 1 , the present embodiment provides a water-cooled condenser 100 , which includes a machine body 20 , a drying assembly 210 , a freezer 30 and a cooling tower 40 .

[0026] read on figure 1 The body 20 includes a compressor 201 , a condenser 205 , a filter drier 207 , an expansion valve 280 , and an evaporator 290 connected in sequence. The evaporator 290 communicates with the compressor 201 , and the compressor 201 is electrically connected to a pressure controller 203 .

[0027] Wherein, the condenser 205 communicates with the dry filter 207 through a first pipeline 209, and the first pipeline 209 is used for the flow of refrigerant.

[0028] Preferably, the dry filter 207 has an alarm detection device (not shown in the figure), and when the refrigerant contains moisture, the dry filter 207 will give an alarm, and then the water absorbing member 260 is installed. It should be noted that the dry filter 207 with an alarm detection device is a co...

no. 2 example

[0058] This embodiment provides a water-removing method for a water-cooled condenser, which can quickly and effectively remove water.

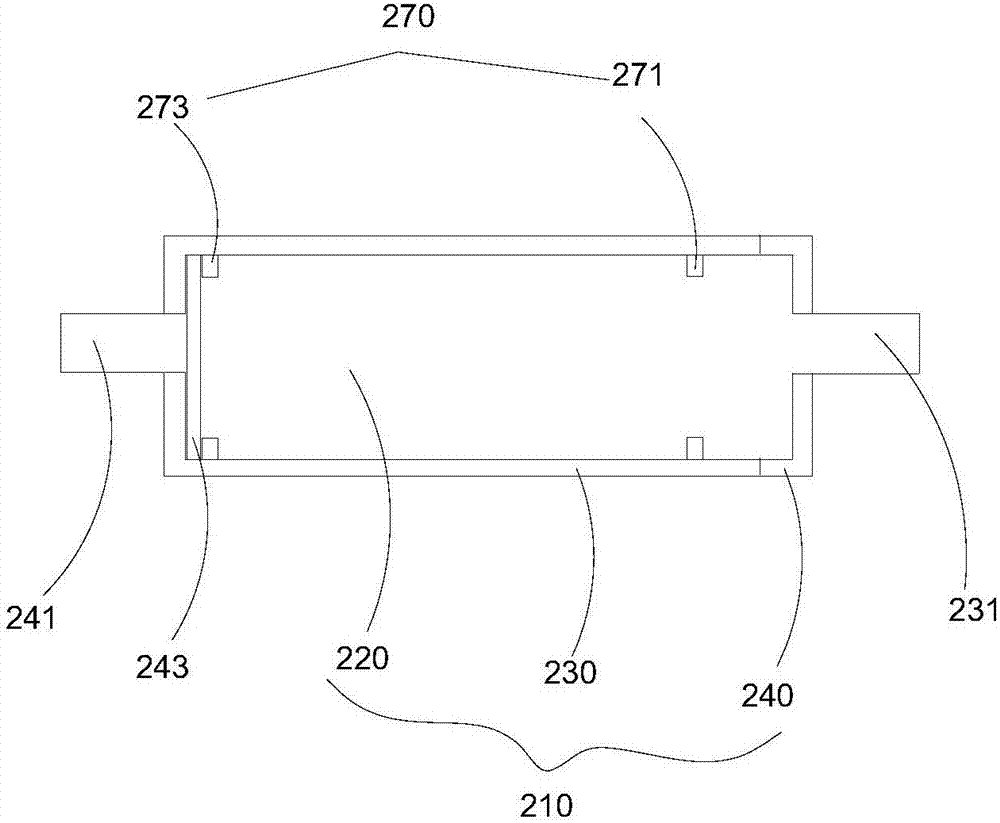

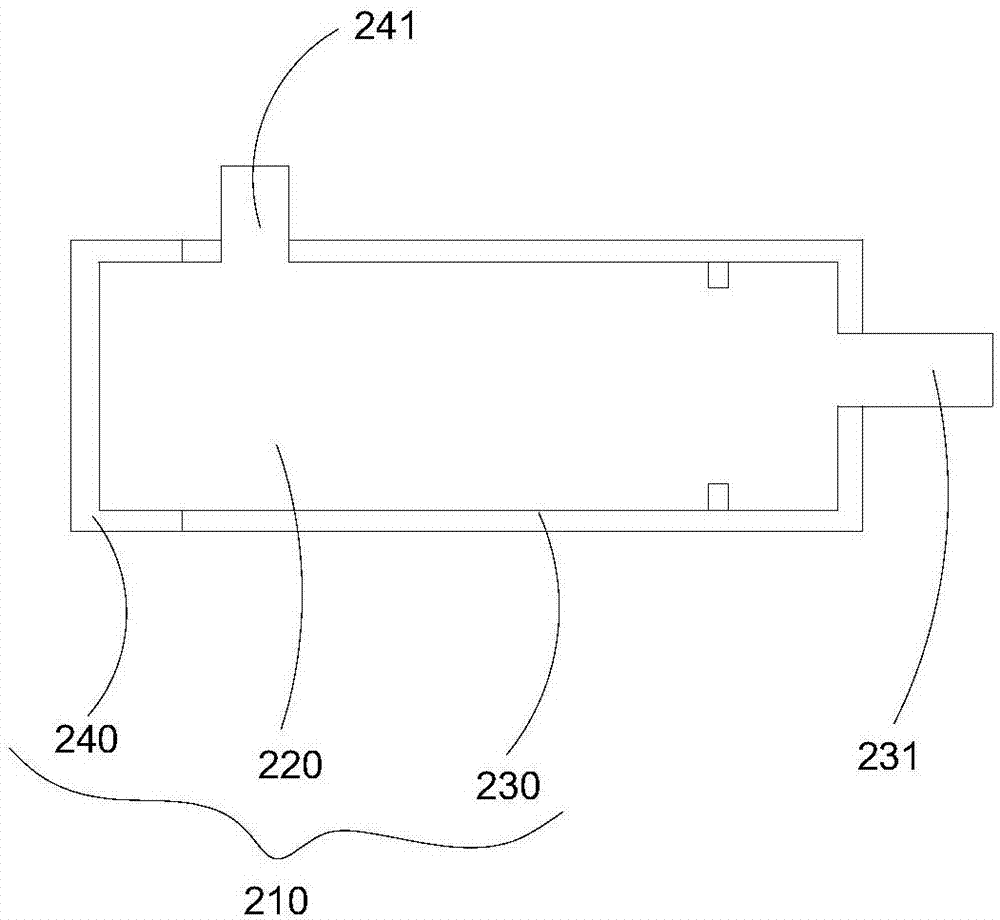

[0059] Among them, the water-cooled condenser includes a body and a water-absorbing part. The body includes a compressor, a condenser, a dry filter, an expansion valve, and an evaporator connected in sequence. The evaporator is connected to the compressor, and the condenser and the dry filter pass through the first The pipes are connected, the first pipe is connected with the drying assembly, the drying assembly is provided with an installation cavity, the water absorbing part is detachably installed in the installation cavity, and the water-cooled condenser is operated to drive the refrigerant in the water-cooled condenser to pass through the drying assembly.

[0060] When there is water in the body, the water-absorbing part will absorb the water and remove the water. Preferably, the water absorbing member is replaced every one to two days to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com