Line contact weighing device

A weighing device and line contact technology, applied in the field of weight detection scales and weight grading, can solve the problems of high cost, affecting weighing accuracy, weight loss of contents, etc., to improve weighing accuracy, improve weighing accuracy, and weigh The effect of precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

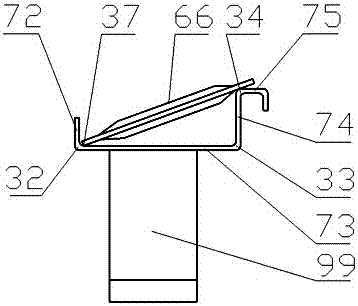

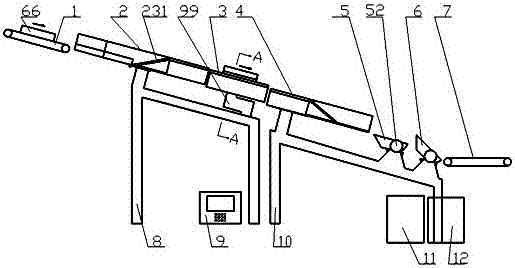

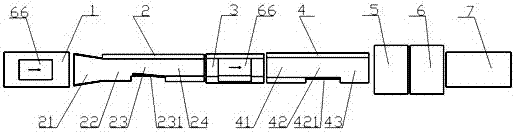

[0054] Embodiment one: if Figure 2-3 As shown, a line contact slideway weighing device includes a control box 9, a support 8, a load cell 99 fixed on the support 8, and a load cell 99 is fixed with a weighing slide for object sliding and weighing. Road 3.

[0055] figure 1It is a schematic diagram of the contact between the lower left part of the weighed object 66 on the weighing slideway 3 and the inner arc of the lower left bending line. It includes that the weighing chute 3 is a smooth groove-like structure with openings at both ends along the running direction of the object 66 to be weighed and a concave cross-section. The left vertical plate 72 on the left side, the right vertical plate 74 located on the right side of the weighing slideway 3, and the slideway bottom plate 73 connecting the right vertical plate 74 and the left vertical plate 72, the intersection of the left vertical plate 72 and the slideway bottom plate 73 corresponds to The lower left bending line 32...

Embodiment 2

[0075] Embodiment two, Figure 5 It is a schematic diagram of the contact between the lower left part of the object and the upper surface of the bottom plate of the slideway. A linear contact slideway weighing device, the same as the first embodiment will not be repeated, the difference is that the lower left part of the object to be weighed 66 is in contact with the upper surface of the slideway bottom plate 73 on the inner side of the left part of the weighing slideway 3 , but the inner side of the left vertical plate 72 of the weighing slideway 3 is relatively close to the left side of the object to be weighed 66, which can reduce the requirements for the feeding accuracy of the front-stage feeding mechanism. When starting to slide, the left side of the object to be weighed 66 did not contact the left vertical plate inner side of the weighing slideway 3 .

[0076] The object 66 to be weighed is a thicker rigid paper packaging box, weighing 25g, and its length, width and he...

Embodiment 3

[0081] Embodiment three, as Image 6 As shown, a line contact slideway weighing device, the same as Embodiment 1 will not be repeated, the difference is that the slideway bottom plate 73 on the inner side of the left lower part of the weighed object 66 and the left part of the weighing slideway 3 The upper surface and the inner arc corresponding to the lower left bending line 32 are in contact at the same time.

[0082] The object to be weighed is a thinner soft object to be weighed 55, which is a plastic flexible packaging bag with bulk material inside with an actual weight of 5±0.1g, and the size is 50mmx50mmx4mm. The feeding unit and speed are the same as before.

[0083] The test results of the existing slideway weighing technology are as follows: the standard deviation of continuous weighing of 20 packs is 0.025g, and the peak-to-peak error is 0.075g.

[0084] like Image 6 As shown, the height of the left vertical plate 72 of the weighing slideway 3 of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com