Residual life prediction method for non-stationary degradation process with uncertain impact

A life prediction and non-stationary technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as equipment impact and achieve accurate online remaining life prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

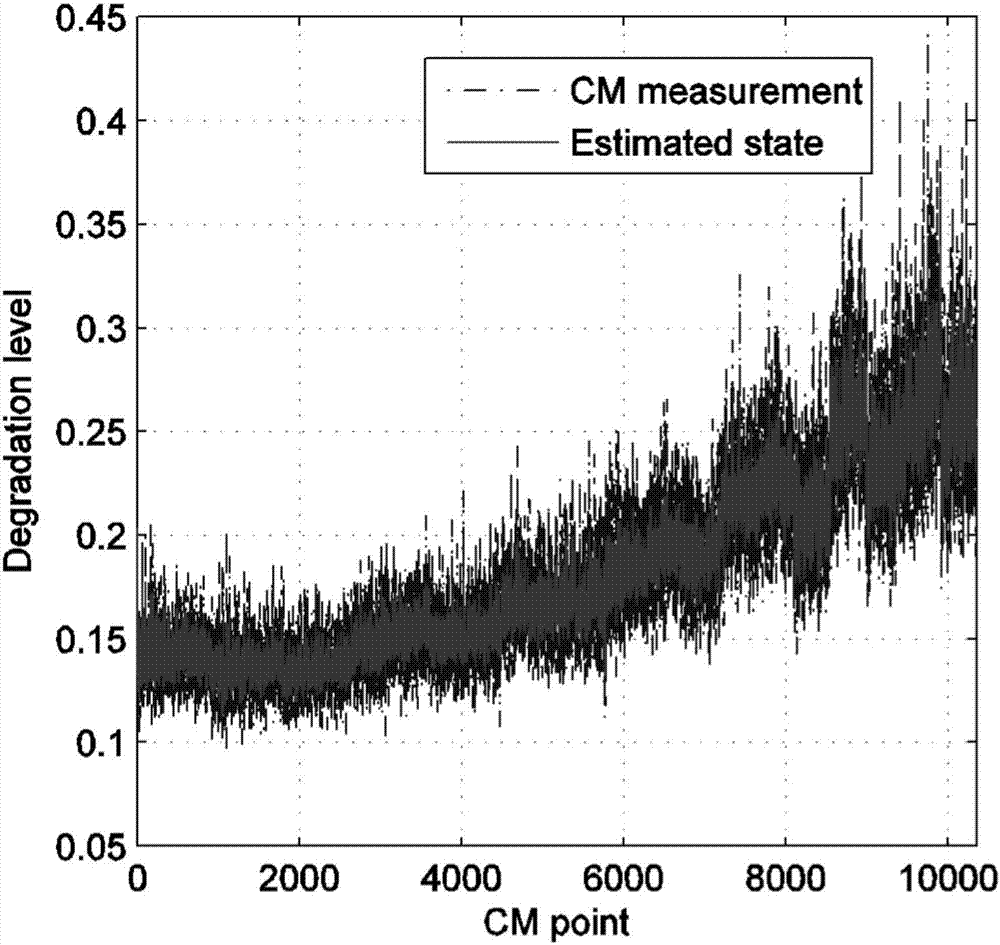

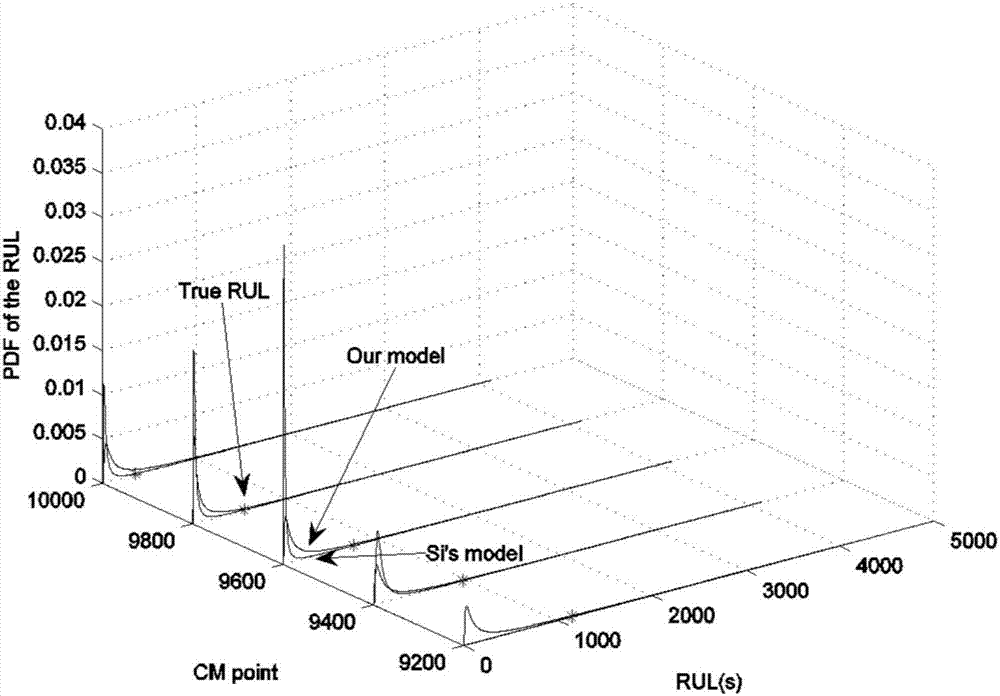

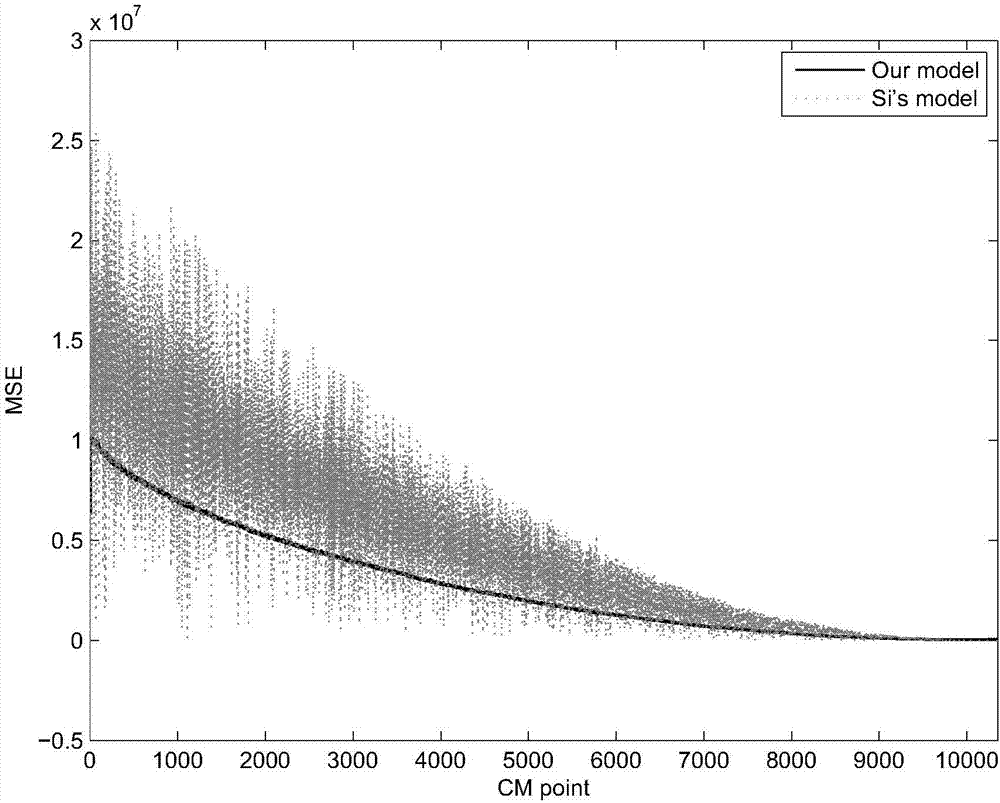

[0065] The specific implementation of the present invention will now be further described in conjunction with the accompanying drawings. Part of the principles have been described in detail above and will not be repeated here. The following example uses a real case based on milling machine data to illustrate the specific operation steps and verify the performance of the proposed model.

[0066] This milling machine data records the degradation of the operation of cutting metallic materials with milling cutters. The case includes 16 different operating conditions, variables including depth of cut, material properties, feed rate, etc. Each case contains multiple cutting processes and terminates when the equipment reaches the failure threshold. This example takes a case as an example and uses the signal of its acoustic wave sensor as the degradation indicator. In order to better verify the performance of the model, this example uses another effective adaptive model (denoted as S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com