Special remote controller mechanical arm for high voltage test

A technology of high-voltage testing and manipulators, which is applied in the direction of program-controlled manipulators, manipulators, chucks, etc., can solve the problems of cumbersome on-site placement, high labor intensity, and low labor efficiency, and achieve simple and convenient control, reduce labor intensity, and improve labor efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

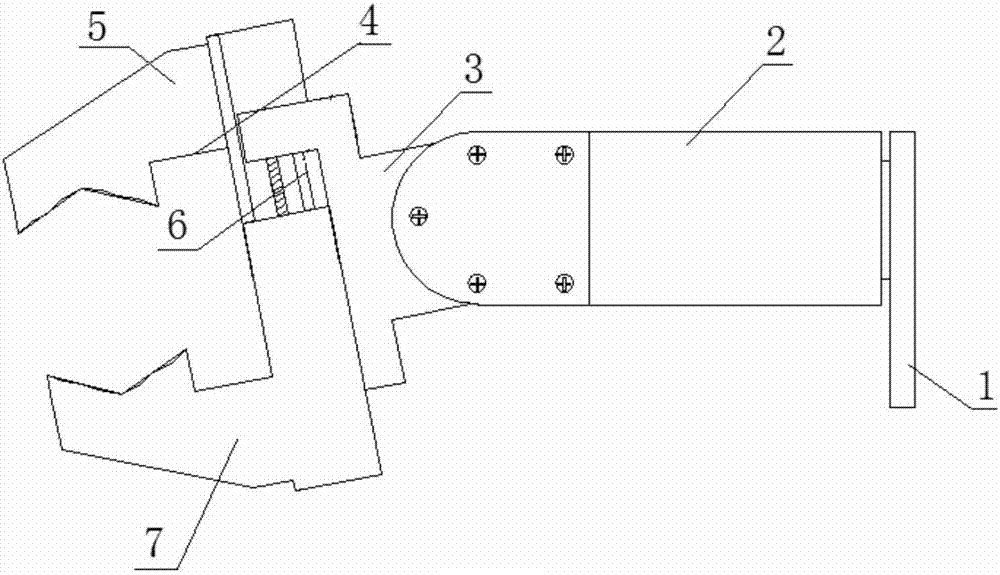

[0026] Embodiment 1: as Figure 1~Figure 5 As shown, a special remote-controlled manipulator for high-voltage testing, including a base 1, a rotating shaft 2, a bite forceps seat 3, and a bite forceps 4, one end of the rotating shaft 2 is rotatably connected to the base 1 through a rotary drive mechanism, and the other end is passed through The pitch driving mechanism is connected to the bite pliers base 3, and the bite pliers 4 which is conductive is connected to the bite pliers base 3.

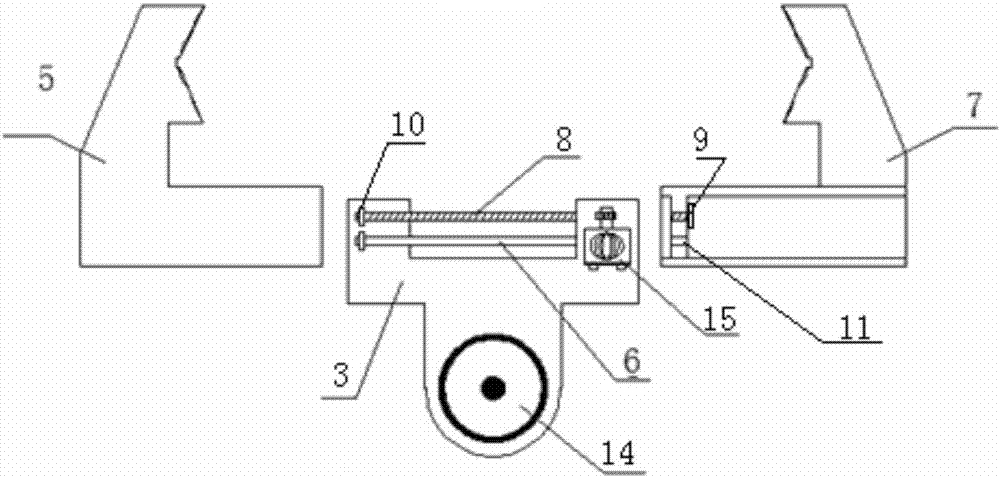

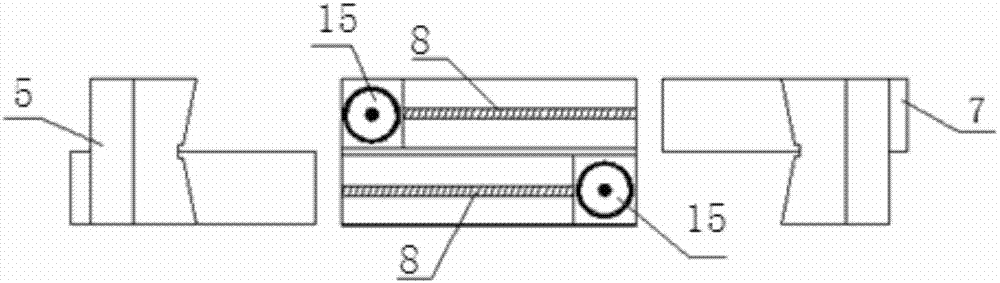

[0027] Preferably, the above-mentioned snapping pliers 4 include snapping claw one 5 and snapping claw two 7, and snapping claw one 5 and snapping claw two 7 are all connected to the snapping pliers base 3 through the screw nut screw auxiliary drive mechanism and are engaged The occlusal surfaces of the jaw one 5 and the jaw two 7 form an occlusal jaw.

[0028] Preferably, each set of above-mentioned screw nut lead screw auxiliary driving mechanism includes a lead screw 8 and a screw nut 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com