Automated stereoscopic warehouse for belt wheel cage trolleys

A technology of three-dimensional warehouses and wheel cage vehicles, which is applied in the field of automated storage equipment, can solve problems such as difficult first-in first-out, difficulty in enterprise management, loss of sluggish materials, etc., and achieve the effect of saving storage costs and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

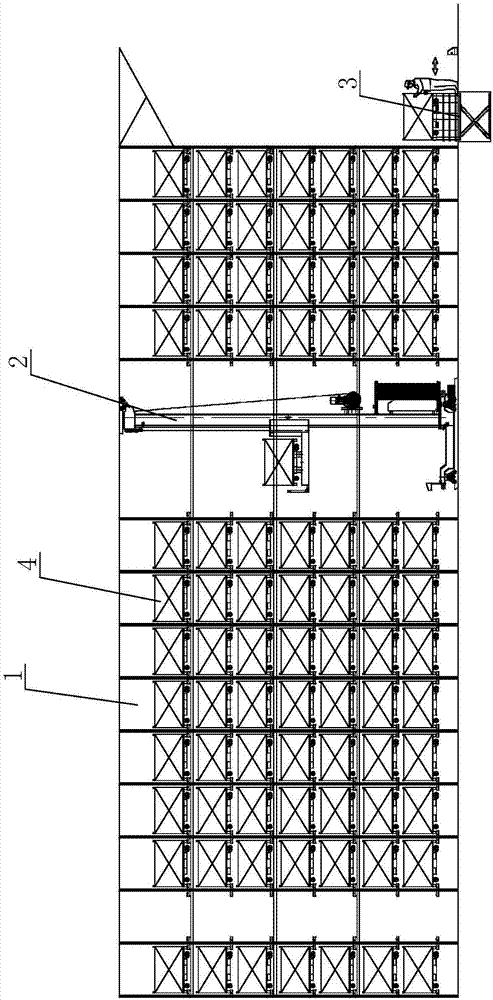

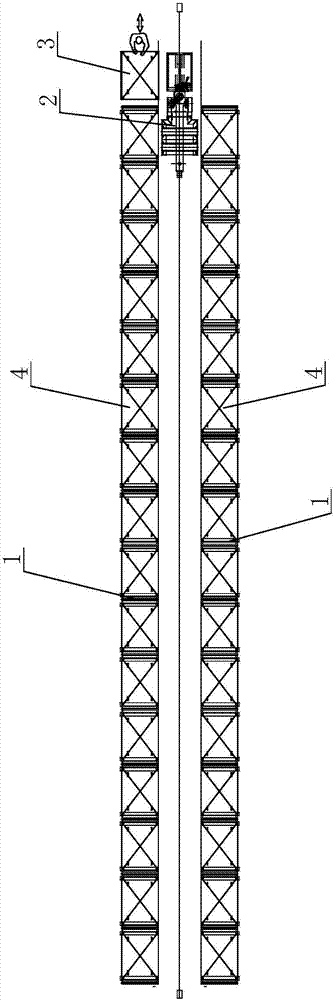

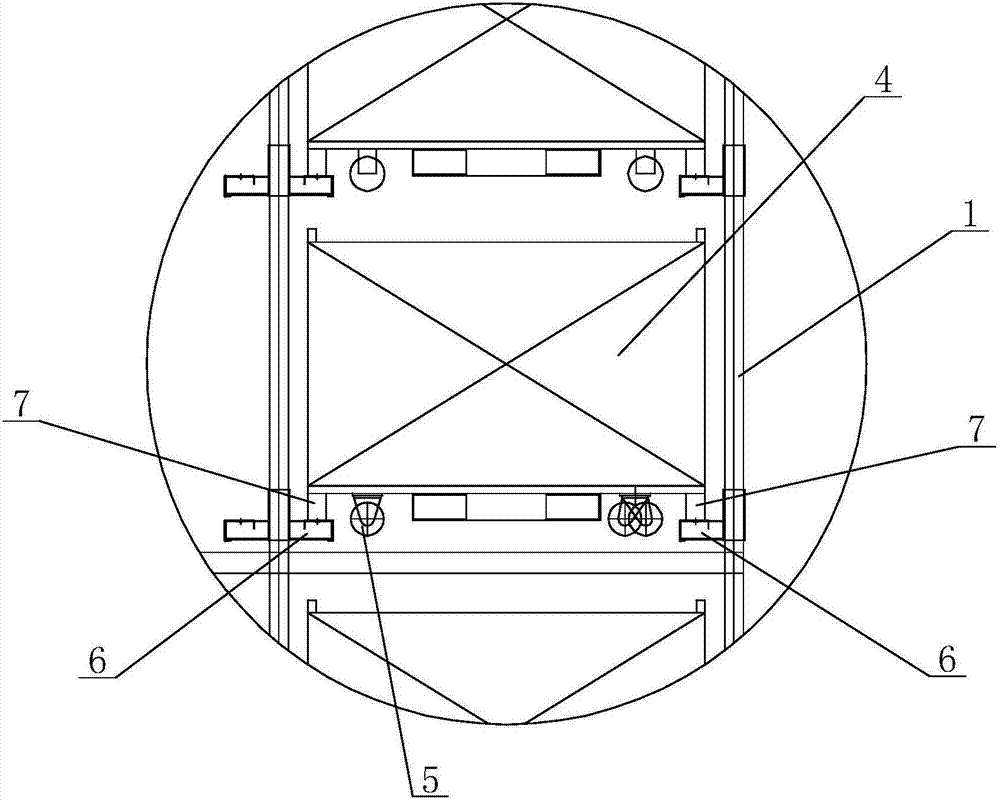

[0017] see Figure 1 to Figure 5 As shown, in this embodiment, an automated three-dimensional warehouse with a wheeled cage car is applied to the storage of finished and semi-finished products in the auto parts production workshop, including two high-level shelves 1, a roadway stacker 2, a hydraulic lifting platform 3 and an automatic Control system, the high-level rack 1 has 224 cargo positions, and can store 224 wheeled cage cars 4. The two high-level racks 1 are arranged at intervals to form a roadway in the center, and the roadway stacker 2 is located on the two high-level racks 1 Between, the hydraulic lifting platform 3 is located at one end of one of the high racks 1 .

[0018] In the design process of the high-level shelf 1, the position avoidance of the shelf structure and the running whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com