Coal mine vertical wind well explosion-proof door advanced explosion venting device and explosion-proof door

A technology of explosion-proof doors and vertical air shafts, which is applied in mine/tunnel ventilation, mining equipment, earthwork drilling, etc., can solve the problems of difficulty in popularizing new type of vertical air shaft explosion-proof doors, high construction and upgrading costs, and achieve enhanced explosion-proof capabilities and Safety and reliability, small amount of engineering, good anti-knock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

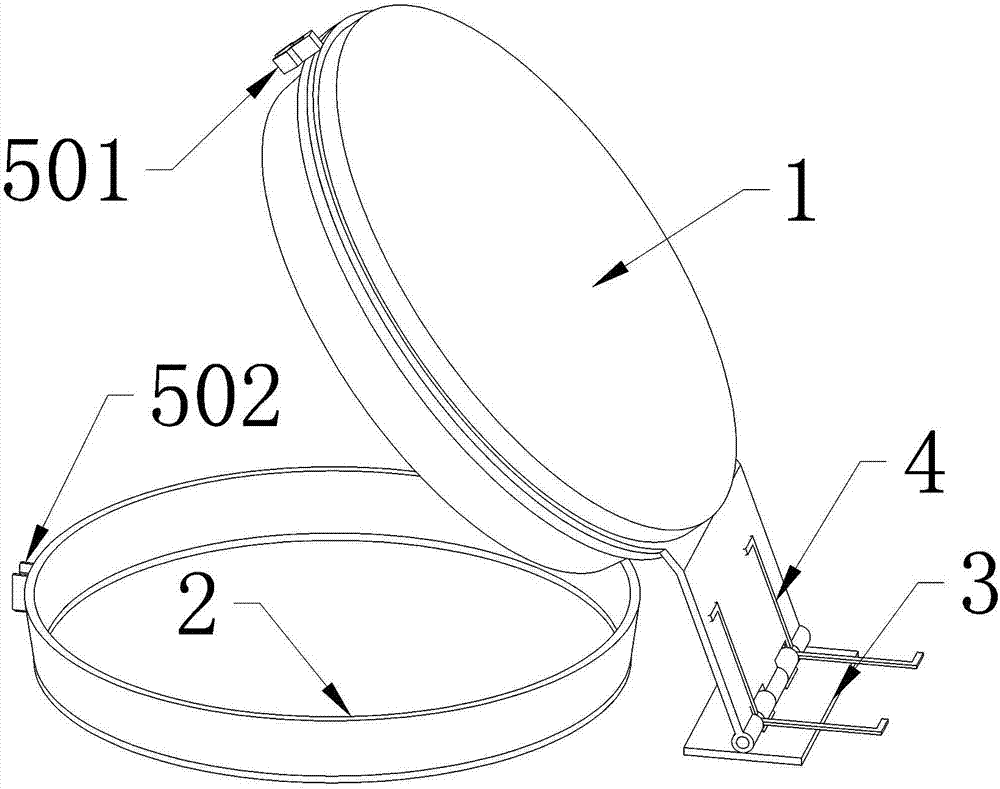

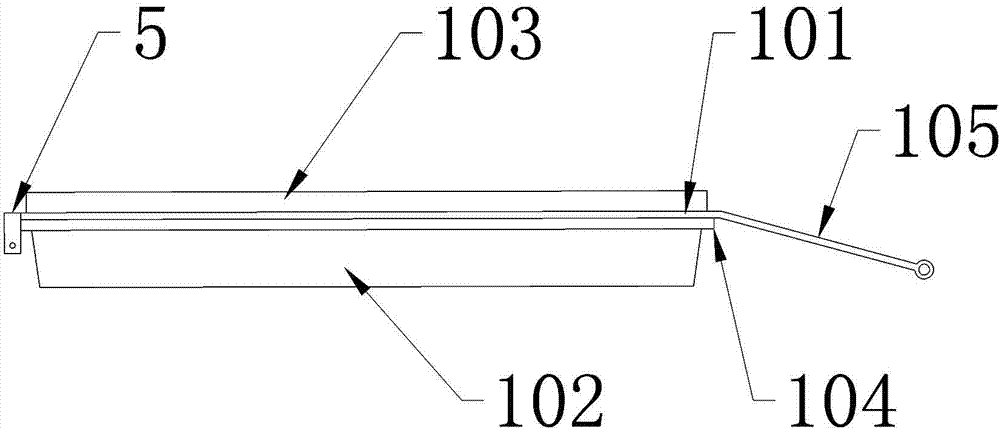

[0028] Such as figure 1 , image 3 , Figure 4 and Figure 5 As shown in the figure, a coal mine vertical air shaft explosion-proof door advance explosion-venting device and explosion-proof door, including umbrella-type door body (M) and the first explosion-venting device;

[0029] The advance explosion venting device includes an explosion venting cover (1), a base (2), a hinge seat (3), a return spring (4), and an anti-wind lock (5); the explosion venting cover (1) includes a metal cover plate (101), a sealing block (102) bonded to the lower surface of the metal cover (101), and a buffer pad (103) bonded to the upper surface of the metal cover (101); the base (2) It is a steel inverted conical cylinder, the sealing block (102) is a table-shaped body closely matched with the base (2); the metal cover (101) is provided with a hinge (105) on one side, and the hinge The head (105) is hinged on the hinge base (3) through the hinge shaft; the coil part of the return spring (4) ...

Embodiment 2

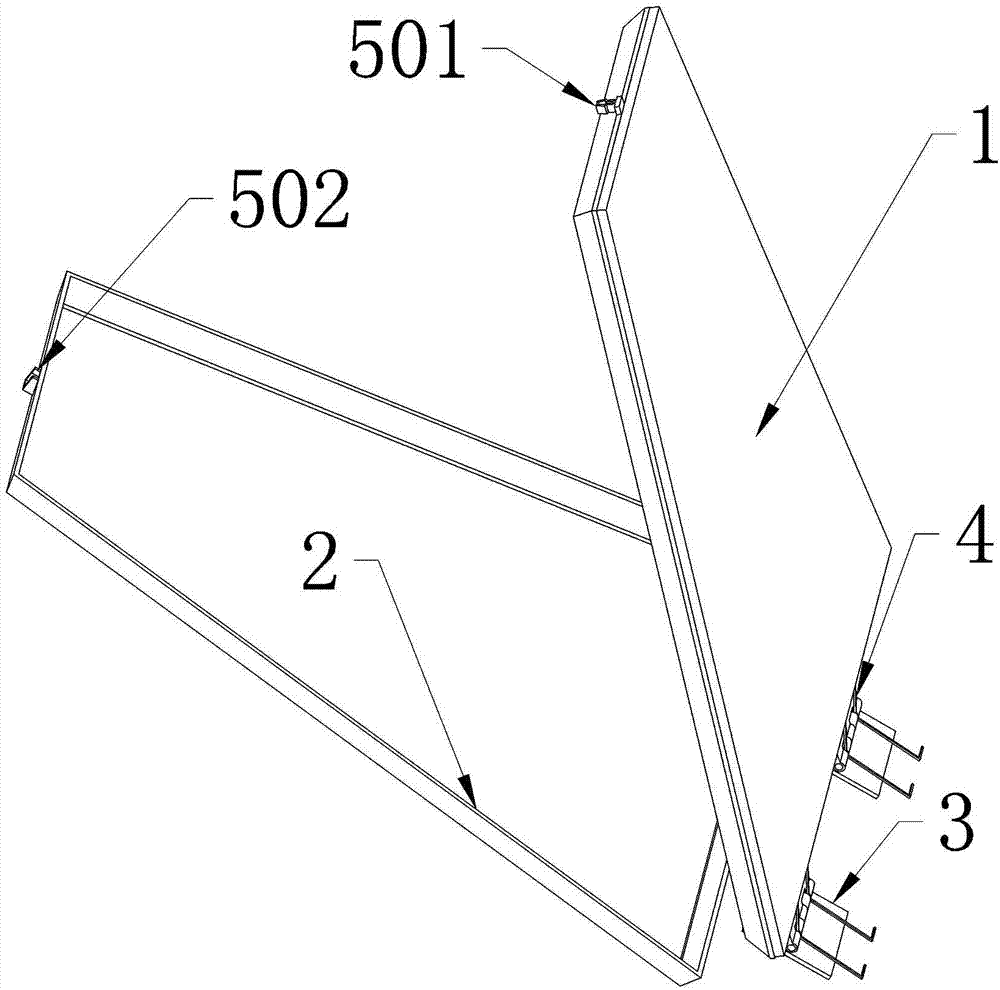

[0032] Such as figure 2 , image 3 , Figure 6 and Figure 7 As shown in the figure, a coal mine vertical air shaft explosion-proof door advance explosion-venting device and explosion-proof door, including umbrella-type door body (M) and the first explosion-venting device;

[0033] The advance explosion venting device includes an explosion venting cover (1), a base (2), a hinge seat (3), a return spring (4), and an anti-wind lock (5); the explosion venting cover (1) includes a metal cover plate (101), a sealing block (102) bonded to the lower surface of the metal cover (101), and a buffer pad (103) bonded to the upper surface of the metal cover (101); the base (2) It is a steel inverted conical cylinder, the sealing block (102) is a table-shaped body closely matched with the base (2); the metal cover (101) is provided with a hinge (105) on one side, and the hinge The head (105) is hinged on the hinge base (3) through the hinge shaft; the coil part of the return spring (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com