Method for displaying metallographic microstructure of cobalt and nickel based wrought superalloy

A technology of deformed superalloy and microstructure, which is used in the display of metallographic microstructure of nickel-based deformed superalloy, the display agent of metallographic microstructure of cobalt and nickel-based deformed superalloy, and the display of metallographic microstructure and morphology, which can solve the problem of metallographic microstructure. The display effect is not ideal, the efficiency is low, and it cannot meet the needs of large-scale production, so as to achieve the effect of improving the efficiency of metallographic inspection and the quality of tissue display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method of this implementation case includes the following steps:

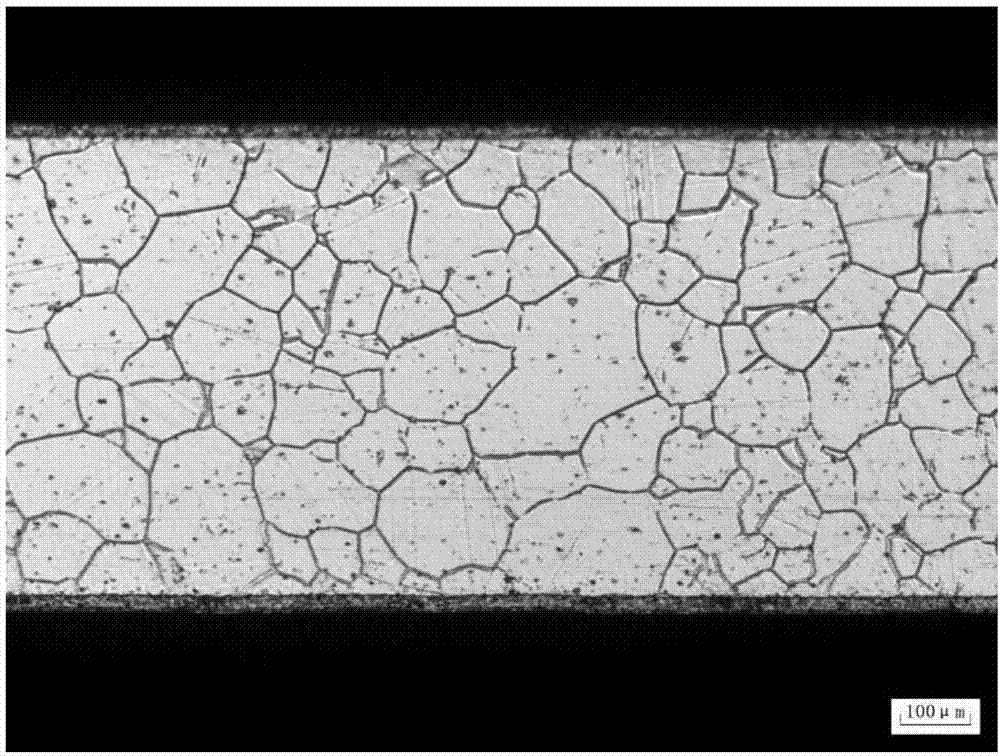

[0022] 1. Take a 0.5mm cold-rolled metallographic sample of GH141 alloy, and obtain a bright and smooth metallographic observation surface after rough grinding and fine grinding and polishing of the sample.

[0023] 2. Calculated by mass percentage, mix 40% hydrochloric acid, 40% 30% hydrogen peroxide, and 20% water to form a chemical etching solution, put it in a glass beaker, soak the prepared metallographic sample in the solution for 3 seconds and take it out , immediately rinse with running water and blow dry.

[0024] 3. Observe the sample treated in step 2 under a metallographic microscope.

[0025] The cold-rolled metallographic structure of the GH141 alloy observed in this embodiment is as follows: figure 1 .

Embodiment 2

[0027] The method of this implementation case includes the following steps:

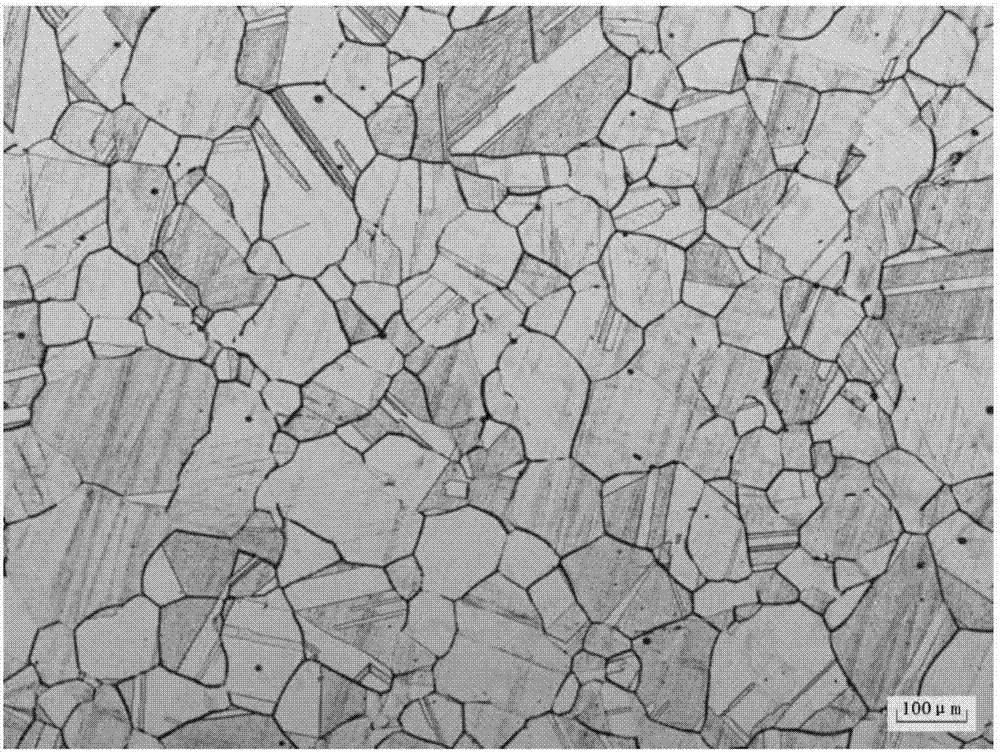

[0028] 1. Take a Φ20mm forged metallographic sample of GH605 alloy, and obtain a bright and flat metallographic observation surface after rough grinding and fine grinding and polishing of the sample.

[0029] 2. Calculated by mass percentage, mix 40% hydrochloric acid, 40% 30% hydrogen peroxide, and 20% water to form a chemical etching solution, put it in a glass beaker, soak the prepared metallographic sample in the solution for 3 seconds and take it out , immediately rinse with running water and blow dry.

[0030] 3. Observe the sample treated in step 2 under a metallographic microscope.

[0031] The forged metallographic structure of GH605 alloy Φ20mm observed in this example is as follows figure 2 .

Embodiment 3

[0033] The method of this implementation case includes the following steps:

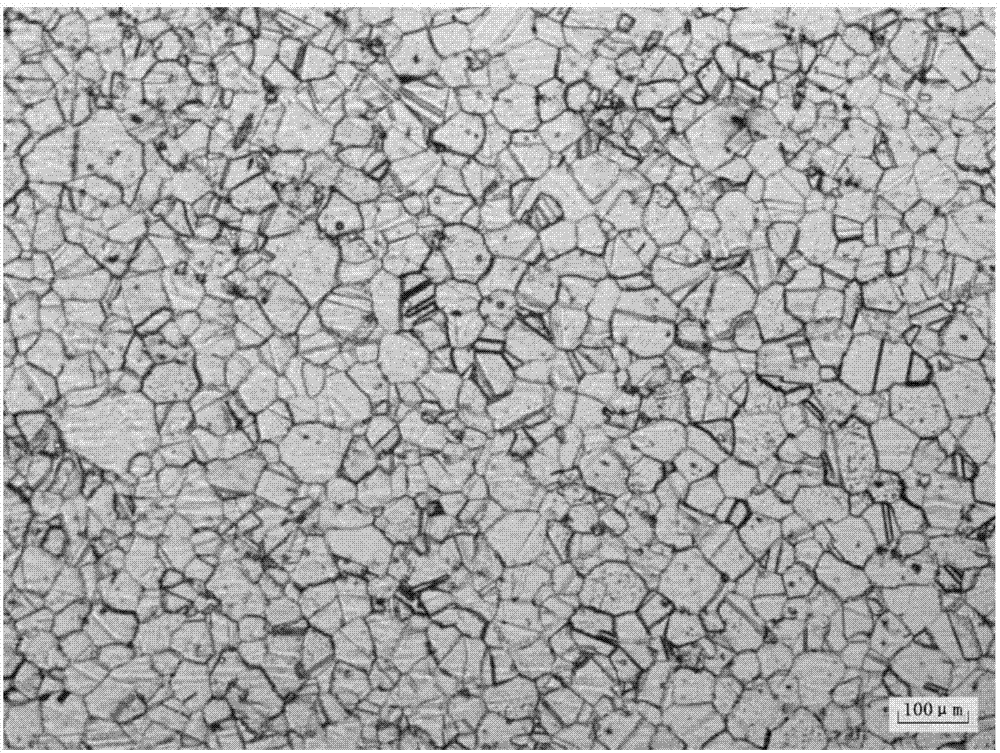

[0034] 1. Take a 5.0mm hot-rolled metallographic sample of GH4169 alloy, and obtain a bright and flat metallographic observation surface after rough grinding and fine grinding and polishing of the sample.

[0035] 2. Calculated by mass percentage, mix 40% hydrochloric acid, 40% 30% hydrogen peroxide, and 20% water to form a chemical etching solution, put it in a glass beaker, soak the prepared metallographic sample in the solution for 3 seconds and take it out , immediately rinse with running water and blow dry.

[0036] 3. Observe the sample treated in step 2 under a metallographic microscope.

[0037] The GH4169 alloy 5.0mm hot-rolled metallographic structure observed in this embodiment is as follows image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com