Transition structure from dielectric suspended line circuit to rectangular waveguide

A rectangular waveguide and dielectric integration technology, applied in circuits, waveguide-type devices, electrical components, etc., can solve the problems of difficult to solve the problems of dielectric integrated suspension line circuit integration testing, low quality factor, and high loss

- Summary

- Abstract

- Description

- Claims

- Application Information

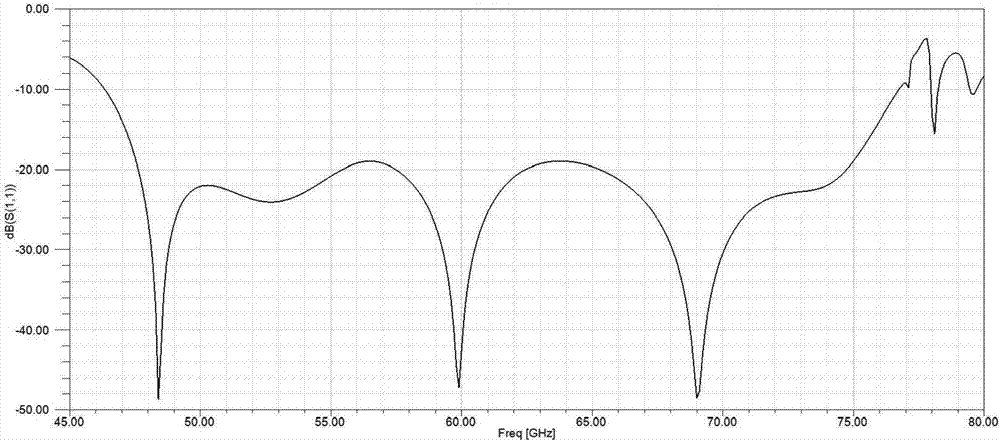

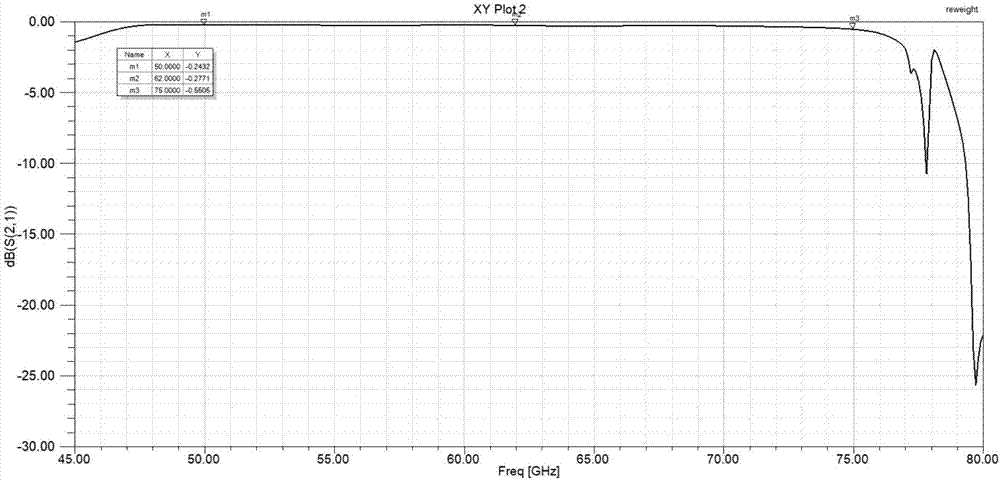

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

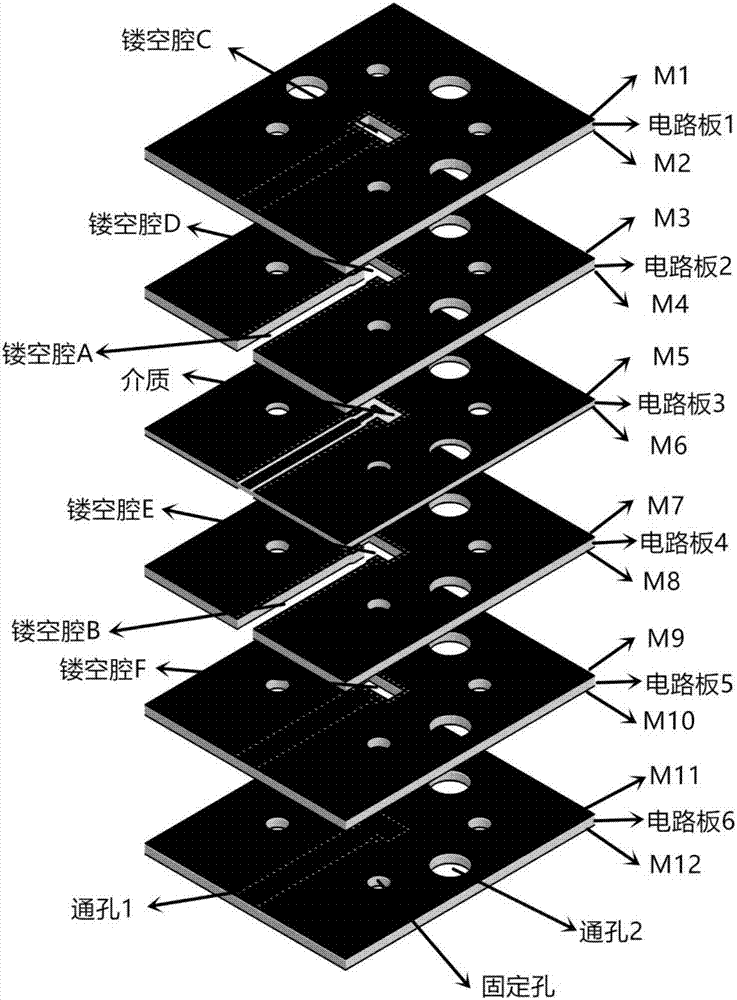

[0042] Embodiment 1: For ordinary multi-layer circuit board riveting, when the number of circuit boards is 6, the 6 circuit boards are respectively the first circuit board, the second circuit board, the third circuit board, the fourth circuit board, the fifth The circuit board, the sixth circuit board, the local area of the second circuit board is partially hollowed out to form a hollow cavity A, and the local area of the fourth circuit board is partially hollowed out to form a hollow cavity B. The metal on the reverse side of the first circuit board layer covering the top of the hollow cavity A, the metal layer on the front of the third circuit board covers the bottom of the hollow cavity A, and the hollow cavity A is composed of the metal layer on the front of the third circuit board and the metal layer on the back of the first circuit board Suspension line air cavity structure, the metal layer on the reverse side of the third circuit board is covered above the hollow cav...

Embodiment approach 2

[0047] Embodiment 2: (that is, replace the first circuit board and the third circuit board with three circuit boards respectively in scheme 1, which also shows that this invention can use several circuit boards for each circuit board in the original medium integrated suspension line board, which embodies the arbitrariness of the invention) For common multilayer circuit board riveting, when the number of circuit boards is 10, the 10 circuit boards are respectively the first circuit board, the second circuit board, and the third circuit board , the fourth circuit board, the fifth circuit board, the sixth circuit board, the seventh circuit board, the eighth circuit board, the ninth circuit board, the tenth circuit board, the local area of the fourth circuit board is partially hollowed out to form a hollow Cavity A, the local area of the sixth circuit board is partially hollowed out to form a hollow cavity B, the metal layer on the reverse side of the third circuit board is cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com