Seeding and furrowing integrated device

A combined device, sowing and ditching technology, which is applied to single-seed seeders, planter parts, and digging/covering ditches, etc., can solve the problems of low production output, difficult seeds falling easily, high labor intensity, etc., and achieve High production yield, good seeding effect, and low labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

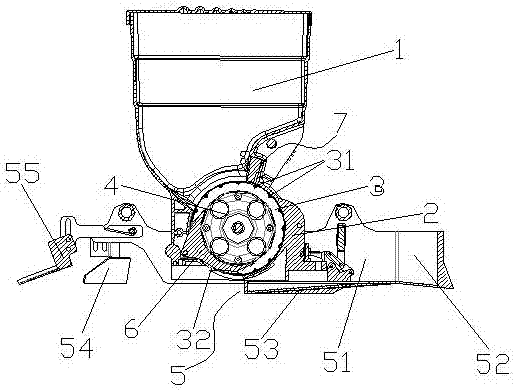

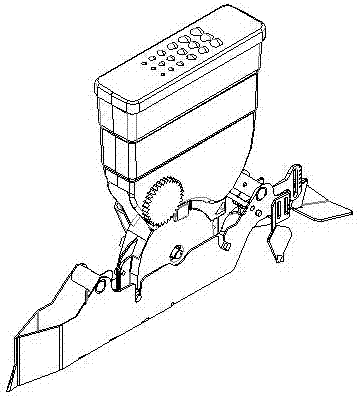

[0016] see figure 1 , figure 2 , an integrated device for sowing and ditching, comprising a seeding box 1, a base 2, a seed box 3, a seed runner 4 and a ditching boat 5, the seeding box 1 is arranged above the base 2, and the seed box 3 is arranged on The base 2 is in communication with the feeding hole of the seeding box 1. The seed wheel 4 is set in the seed box 3 and drives the seed box 3 to rotate. Several unidirectional seed entry holes 31 are evenly and symmetrically arranged in the seed box 3. And one side of the bottom is provided with a seed outlet hole 32, and the ditching boat 5 is located at the bottom of the seed box 3, and the ditching boat 5 includes a metal skeleton 51, a plow share 52 arranged at the front end, and a V-shaped paddle arranged at the bottom. Line block 53, a group of outer splayed soil covering sheets 54 loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com