Application of plant dyeing yarn in infant clothes and application method

A technology of plant dyeing and application method, applied to the application field of plant dyed yarn in infant clothing, can solve the problems of high cost, unfavorable promotion and application of excellent technology, no woven accessories, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

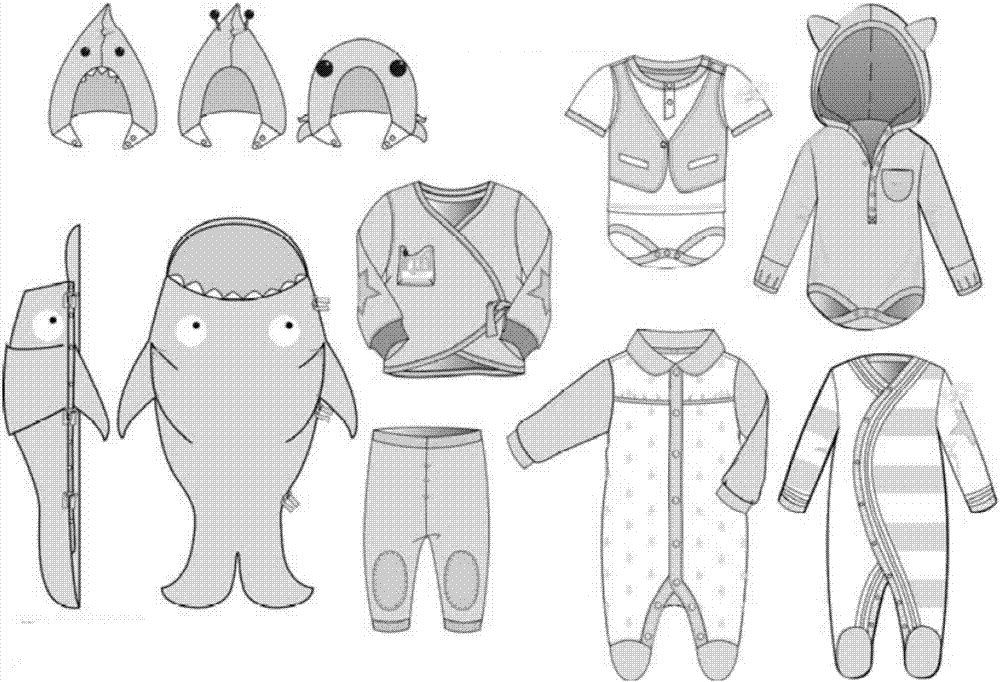

Image

Examples

Embodiment 1

[0045] The application method of plant dyed yarn in infant clothing includes the following steps:

[0046] S1. Select suitable yarns for dyeing with vegetable dyes to obtain vegetable dyed yarns. Specifically, select vegetable dyes, put the yarns to be dyed into vegetable dyes, and use ultrasonic waves for dyeing processing, where ultrasonic waves use 25KHz and 37KHz The dual-frequency ultrasonic combination, the ultrasonic power intensity is 0.5W / cm 2 , Keep the temperature at 45℃ for 15 minutes; then use ultrasonic wave for soaping processing, among which, the ultrasonic wave adopts a combination of three frequency ultrasonic waves of 30KHz, 42KHz and 60KHz, and keep it at 30℃ for 20 minutes to do soaping twice and wash twice at room temperature. Ultrasonic power intensity is 0.95W / cm 2 ;

[0047] S2. Using the plant dyed yarn obtained in step S1 to spin a plant dyed fabric, including knitted fabric and woven fabric; in this embodiment, the knitted fabric adopts a double-sided st...

Embodiment 2

[0052] The application method of plant dyed yarn in infant clothing includes the following steps:

[0053] S1. Select suitable yarns for dyeing with vegetable dyes to obtain vegetable dyed yarns. Specifically, select vegetable dyes, put the yarns to be dyed into vegetable dyes, and use ultrasonic waves for dyeing processing, where ultrasonic waves use 25KHz and 37KHz The dual-frequency ultrasonic combination, the ultrasonic power intensity is 0.5W / cm 2 , Keep the temperature at 45℃ for 15 minutes; then use ultrasonic wave for soaping processing, among which, the ultrasonic wave adopts a combination of three frequency ultrasonic waves of 30KHz, 42KHz and 60KHz, and keep it at 30℃ for 20 minutes to do soaping twice and wash twice at room temperature. Ultrasonic power intensity is 0.95W / cm 2 ;

[0054] S2. The plant dyed yarn obtained in step S1 is spun to obtain plant dyed fabric, including knitted fabric and woven fabric; in this embodiment, the knitted fabric uses ordinary yarn as ...

Embodiment 3

[0063] The application method of plant dyed yarn in infant clothing includes the following steps:

[0064] S1. Select suitable yarns for dyeing with vegetable dyes to obtain vegetable dyed yarns. Specifically, select vegetable dyes, put the yarns to be dyed into vegetable dyes, and use ultrasonic waves for dyeing processing, where ultrasonic waves use 25KHz and 37KHz The dual-frequency ultrasonic combination, the ultrasonic power intensity is 0.5W / cm 2 , Keep the temperature at 45℃ for 15 minutes; then use ultrasonic wave for soaping processing, among which, the ultrasonic wave adopts a combination of three frequency ultrasonic waves of 30KHz, 42KHz and 60KHz, and keep it at 30℃ for 20 minutes to do soaping twice and wash twice at room temperature. Ultrasonic power intensity is 0.95W / cm 2 ;

[0065] S2. Use the plant dyed yarn obtained in step S1 to spin to obtain plant dyed fabrics, including knitted fabrics and woven fabrics; wherein the knitted fabrics use ordinary yarns as surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com