Preparation method of antibacterial flame-retardant adhesive

A flame-retardant adhesive and adhesive technology, which is applied in the preparation of animal glue or gelatin, adhesives, adhesive additives, etc., can solve the problems of unfriendly environment, unsatisfactory flame retardancy and antibacterial properties, and adhesive cohesion. Poor problems, to achieve the effect of low cost, excellent stability, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

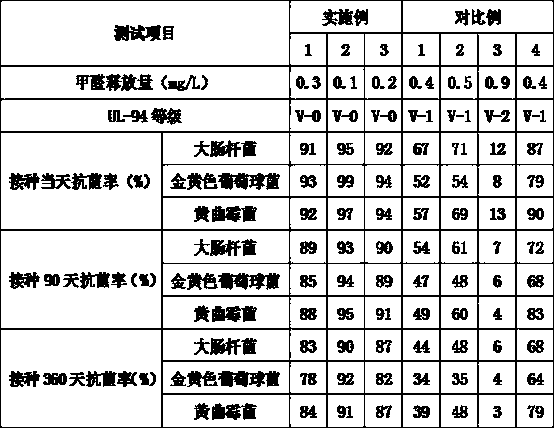

Examples

Embodiment 1

[0020] A kind of preparation method of antibacterial flame retardant adhesive proposed by the present invention comprises the following steps:

[0021] S1, preparation modifier:

[0022] a. Wash the perilla leaves, dry them in vacuum at 40°C, crush them again, add 10 times the mass of ethanol-water mixed solvent to extract twice, each time for 2 hours, the ethanol-water mixed solvent is made from the 10:3 volume ratio of It is made by mixing water, ethanol and water. After extraction, it is filtered, and the combined filtrate is mixed solution A. The mixed solution A is concentrated under reduced pressure to half of its original volume, dried with anhydrous magnesium sulfate, and then filtered. The obtained filtrate is mixed solution A. For liquid B, concentrate the mixed liquid B under reduced pressure, dry it in vacuum at 40°C for 6 hours, grind it, and sieve it, and take the powder that passes through a 200-mesh sieve and does not pass through a 400-mesh sieve, which is per...

Embodiment 2

[0028] A kind of preparation method of antibacterial flame retardant adhesive proposed by the present invention comprises the following steps:

[0029] S1, preparation modifier:

[0030] a. Wash the perilla leaves, dry them in vacuum at 40°C, crush them again, add 10 times the mass of ethanol-water mixed solvent to extract twice, each time for 2 hours, and the ethanol-water mixed solvent is made of non-alcohol with a volume ratio of 5:1. It is made by mixing water, ethanol and water. After extraction, it is filtered, and the combined filtrate is mixed solution A. The mixed solution A is concentrated under reduced pressure to half of its original volume, dried with anhydrous magnesium sulfate, and then filtered. The obtained filtrate is mixed solution A. For solution B, concentrate the mixed solution B under reduced pressure, dry it in vacuum at 40°C for 7 hours, grind it, and sieve it, and take the powder that passes through a 200-mesh sieve but does not pass through a 400-mes...

Embodiment 3

[0036] A kind of preparation method of antibacterial flame retardant adhesive proposed by the present invention comprises the following steps:

[0037] S1, preparation modifier:

[0038] a. Wash the perilla leaves, dry them in vacuum at 40°C, crush them again, add 10 times the mass of ethanol-water mixed solvent to extract twice, each time for 2 hours, and the ethanol-water mixed solvent is made of 20:3 volume ratio It is made by mixing water, ethanol and water. After extraction, it is filtered, and the combined filtrate is mixed solution A. The mixed solution A is concentrated under reduced pressure to half of its original volume, dried with anhydrous magnesium sulfate, and then filtered. The obtained filtrate is mixed solution A. For liquid B, concentrate the mixed liquid B under reduced pressure, dry it in vacuum at 40°C for 8 hours, grind it, and sieve it, and take the powder that passes through a 200-mesh sieve but does not pass through a 400-mesh sieve, which is perilla ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com