Novel multifunctional wound dressing for treating chronic wounds

A chronic wound and multifunctional technology, applied in the field of medical materials, can solve the problems of poor antibacterial and anti-inflammatory effects and high prices, and achieve the effects of easy industrial scale production, short product process, and reduced wound damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A new multifunctional wound dressing for treating chronic wounds, including a base layer, one side of the base layer is provided with a dressing mesh made of copper alloy wire and cotton spinning, and the copper alloy wire and cotton spinning adopt an embedded composite spinning method Wear woven into dressing mesh. The preparation method of the above-mentioned copper alloy wire adopts the following steps: Utilize the vacuum gas protection smelting technology and the down-drawing continuous casting technology to make copper alloy rods, the vacuum gas protection smelting technology can effectively prevent the metal from being oxidized, and make the casting surface more smooth Castings are free of pores, defects and impurities, etc.; at the same time, the down-drawing continuous casting technology can control the density and precision of the material to the greatest extent by drawing copper alloy rods from the melt, and avoid shrinkage cavities or pores. Copper alloy rods...

Embodiment 2

[0038] The difference between this example and Example 1 is that the diameter of the copper alloy ultrafine wire is different, and the diameter of the copper alloy wire obtained in this example is 40 μm. The chemical composition in the copper-iron alloy is percentage by weight: iron (Fe): 1%, and the balance is copper (Cu). The diameter of the iron alloy ultra-fine microwire is 40 μm, the deformation rate is 7%, its tensile strength is 1220Mpa, and the elongation rate after breaking is 10.4%;

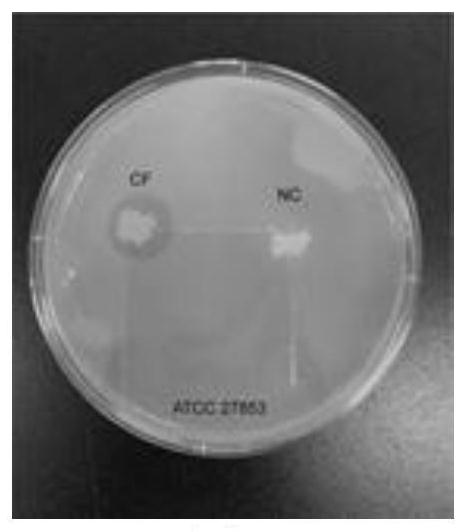

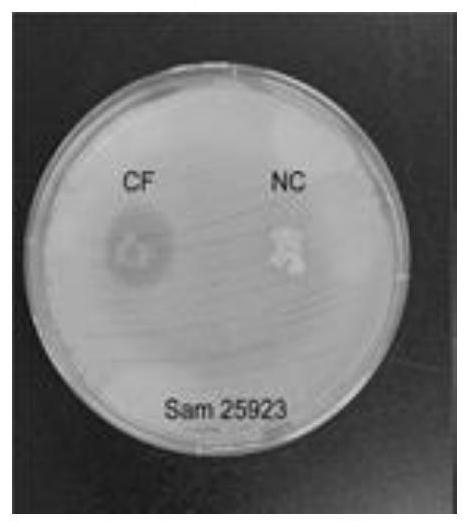

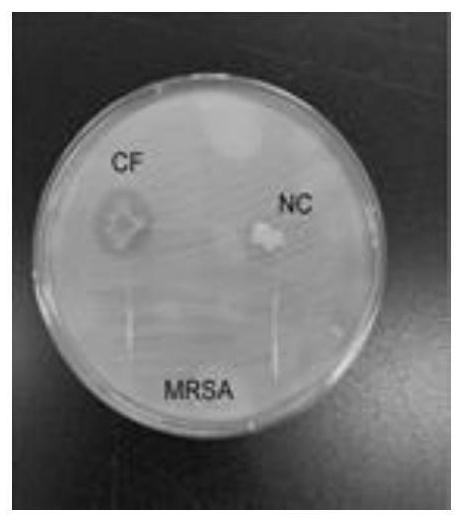

[0039] The qualitative antibacterial performance testing method of the wound dressing of this example is the same as in Example 1, and the results show that the wound dressing of this example has antibacterial effects on ATCC27853, Sam25923, MRSA, and ATCC22019.

[0040] Quantitative measurement: dilution plate method

[0041] Take the ATCC27853 strain solution (concentration 4.5×108CFU / mL) and add it dropwise to the blank control and the wound dressing of this embodiment. Use sterili...

Embodiment 3

[0043] The difference between this example and Example 1 is only that the diameter of the copper alloy ultrafine wire is different, and the diameter of the copper alloy wire obtained in this example is 55 μm. The chemical composition in the copper-iron alloy is percentage by weight: iron (Fe): 3%, and the balance is copper (Cu). The diameter of the obtained copper-iron alloy bar is 12 mm. The diameter of the iron alloy ultrafine microwire is 55 μm, the deformation rate is 6%, its tensile strength is 1120Mpa, and the elongation rate after breaking is 20.1%;

[0044] The qualitative antibacterial property testing method of the wound dressing of this example is the same as that of Example 1, and the results show that the wound dressing of this example has antibacterial effects on ATCC27853, Sam25923, MRSA, and ATCC22019.

[0045] Quantitative measurement: dilution plate method

[0046] Take the ATCC27853 strain solution (concentration 4.5×108CFU / mL) and add it dropwise to the bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com