A tension bend steel plate used for patella fracture

A patella fracture and tension band technology, applied in the field of medical devices, can solve the problems of poor fracture healing, complex mechanical environment, difficult operation, etc., and achieve the effect of saving operation time, simple operation and good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

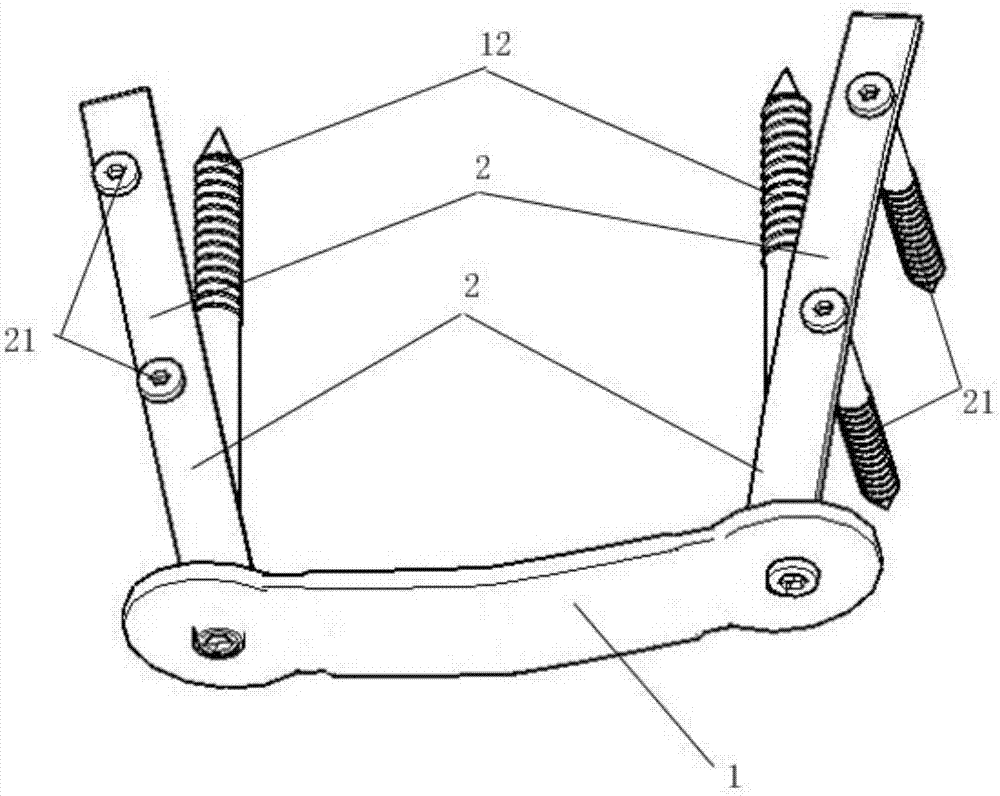

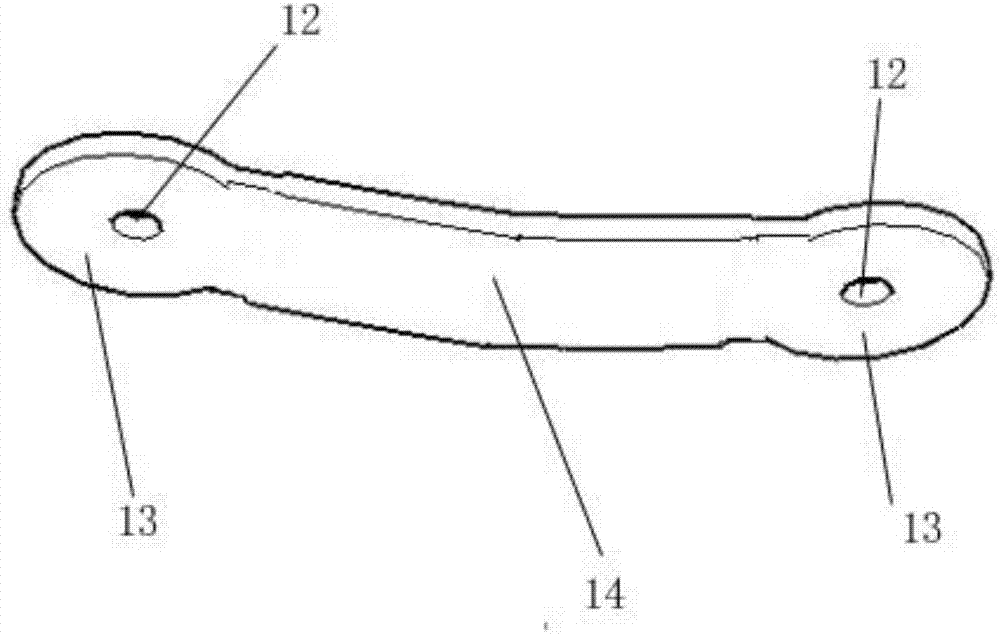

[0034] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] The reference signs and components involved in the accompanying drawings are as follows:

[0036] 1. Horizontal fixing plate 11. Upper and lower pole screws

[0037] 111. Nail cap 112. Nail body

[0038] 113. Nail tip 114. Distal thread

[0039] 115. Proximal thread 12. Upper and lower pole screw holes

[0040] 13. Nail setting part 14. Arc part

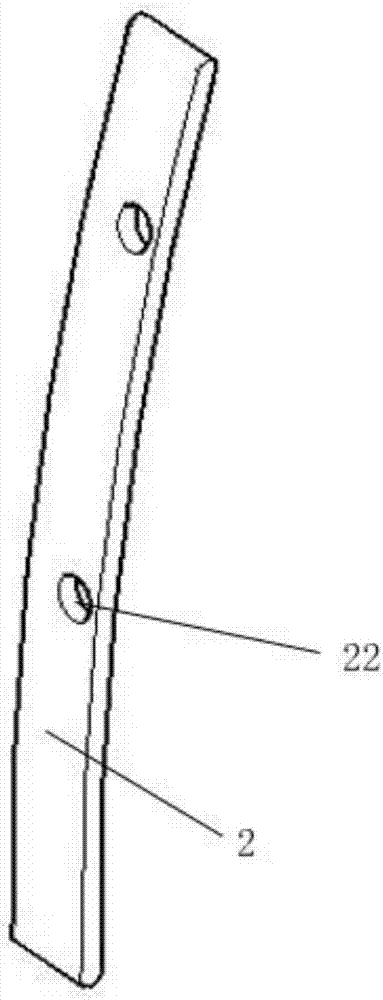

[0041] 2. Longitudinal tension plate 21. Fixing screw

[0042] 22. Fixing screw holes

[0043] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a tension band steel plate used for patella fracture of the present invention. A tension band steel plate for patella fractures, the tension band steel plate includes a transverse fixation plate 1 and a longitudinal tension plate 2; both ends of the transverse fixation plate 1 are connected to a longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com