Full-automatic thin film suction filter

A technology of membrane filtration and suction filter, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as low work efficiency, achieve the effects of improving work efficiency, convenient use, and saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Describe in detail below in conjunction with specific embodiment according to accompanying drawing:

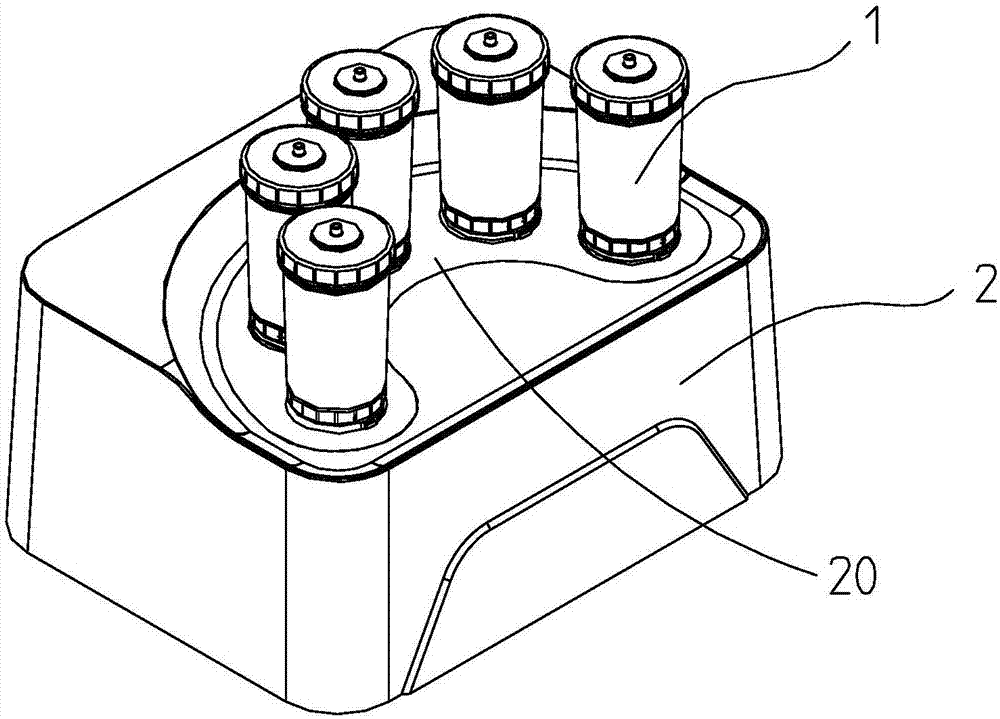

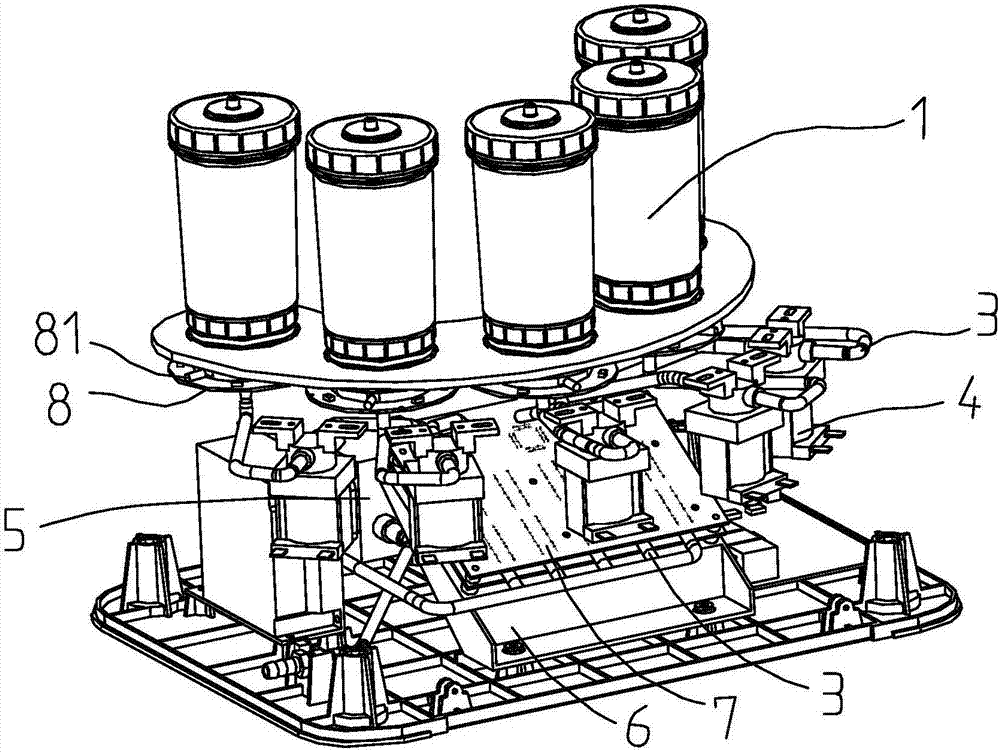

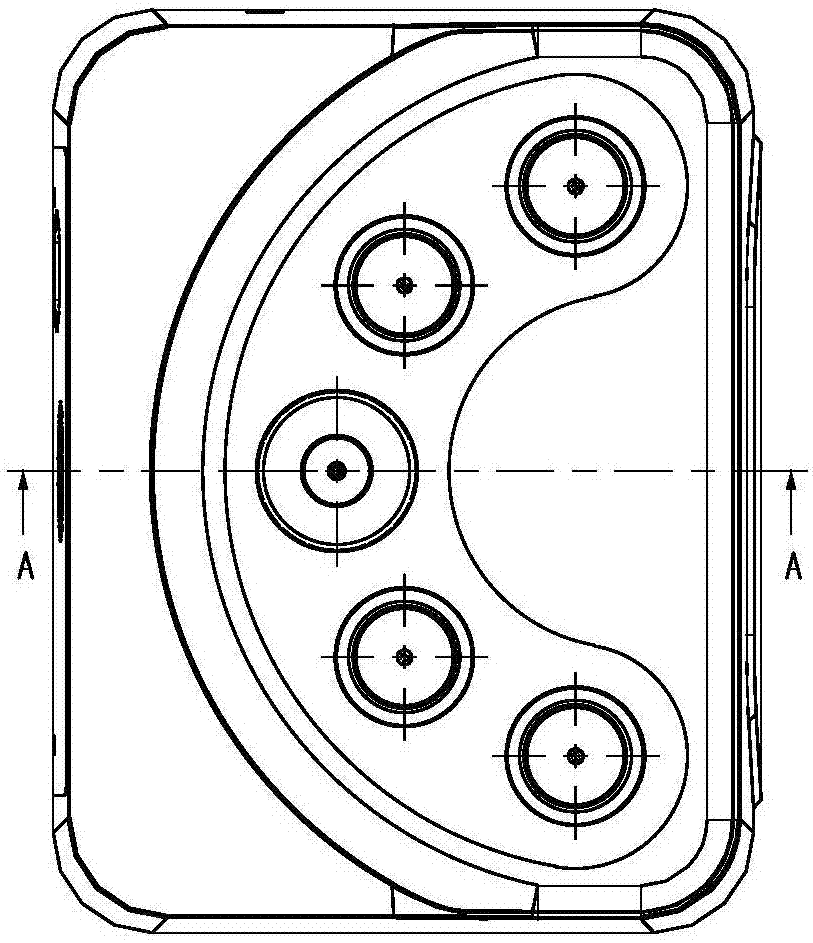

[0039] as attached Figure 1-9 The fully automatic membrane filtration suction filter shown includes a suction filter cup 1, a casing 2, a pipeline 3, a solenoid valve 4, a water pump 5, a liquid sensor 71 and an in-position sensor 81, and at least one suction filter is installed on the casing 2. The filter cup 1, the pipeline 3, the solenoid valve 4, the water pump 5, the liquid sensor 71 and the position sensor 81 are located in the housing 2, and each of the suction filter cups 1 is connected to the water pump 5 through a pipeline 3, and each of the pipelines 3 are provided with a solenoid valve 4, the in-position sensor 81 is set at the position where the suction filter cup 1 is connected to the housing 2, and the in-position sensor 81 is electrically connected to the water pump 5 and the solenoid valve 4 respectively;

[0040] A circuit board 7 is also arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com