A garbage separator

A technology for separating sieves and garbage, which is used in solid separation, sieves, packaging, etc. to achieve high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

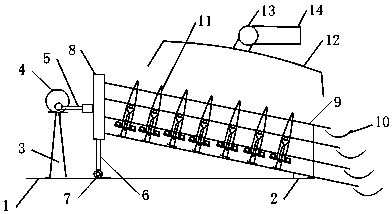

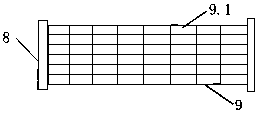

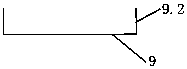

[0014] As shown in the figure, there are oblique four-layer sieve plates 9 connected in layers to the sieve frame 8. The sieve plates are provided with rectangular sieve holes 9.1, and the sieve holes gradually shrink from top to bottom. The screen side 9.2 bent upwards is provided with a conveyor belt 10 on the front side of each sieve plate, a screen frame support 6 is provided at the bottom of the screen frame, and a screen frame ground wheel 7 is installed at the bottom of the screen frame support. Bar 5 is connected with the eccentric wheel of motor 4, and motor is arranged on the bottom plane plate 1 by motor support frame 3, and slide block 2 is housed on the front side of bottom plane plate, and ground wheel is placed on bottom plane plate.

[0015] A suction hood 12 is installed on the top of the first sieve plate, a suction fan 13 is installed at the center of the suction hood, and a discharge port 14 is arranged at the outlet of the suction fan.

[0016] A shift for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com