Cross-belt sorter bin bagging and transferring system based on pass boxes and method

A cross-belt sorting and turnover box technology, applied in sorting and other directions, can solve the problems of wasting labor costs, damage internal packages, and high overall costs, and achieve the effects of improving packaging efficiency, reducing cargo damage, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

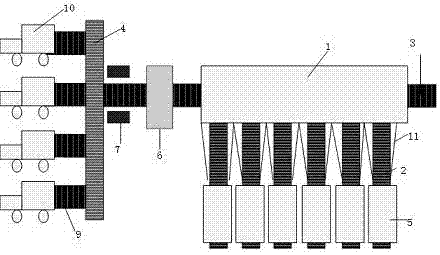

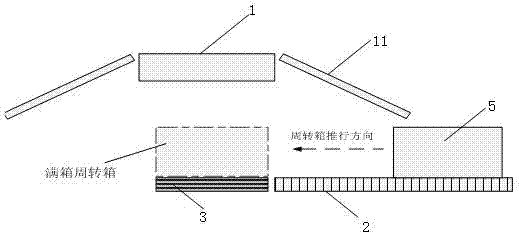

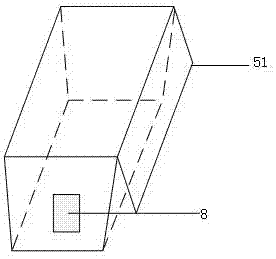

[0022] Such as Figure 1~3 As shown, a turnover case-based cross-belt sorter grid packing transfer system disclosed in the present invention includes a cross-belt sorter 1, a first roller conveyor line 2, a second roller conveyor line 3, and a cross-type Transfer conveyor belt 4, turnover box 5, automatic packing machine 6 and radio frequency reading and writing equipment 7, wherein the second roller conveyor belt 3 is arranged under the cross-belt sorter 1, and the first roller conveyor belt 2 is located at the cross-belt sorter 1 Below each grid, and connected to the second roller conveyor belt 3, one end of the turnover box 5 is affixed with an RFID label 8 (the destination address information of the turnover box is stored inside), and the other end of the side is affixed with a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com