Tubular workpiece grooving machine and machining process thereof

A technology for slotting machines and workpieces, which is applied to metal processing equipment, manufacturing tools, sawing machine devices, etc., can solve the problems of unfavorable mass production, low clamping and processing efficiency, and high processing work intensity, so as to improve production efficiency and structure. Simple, work-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

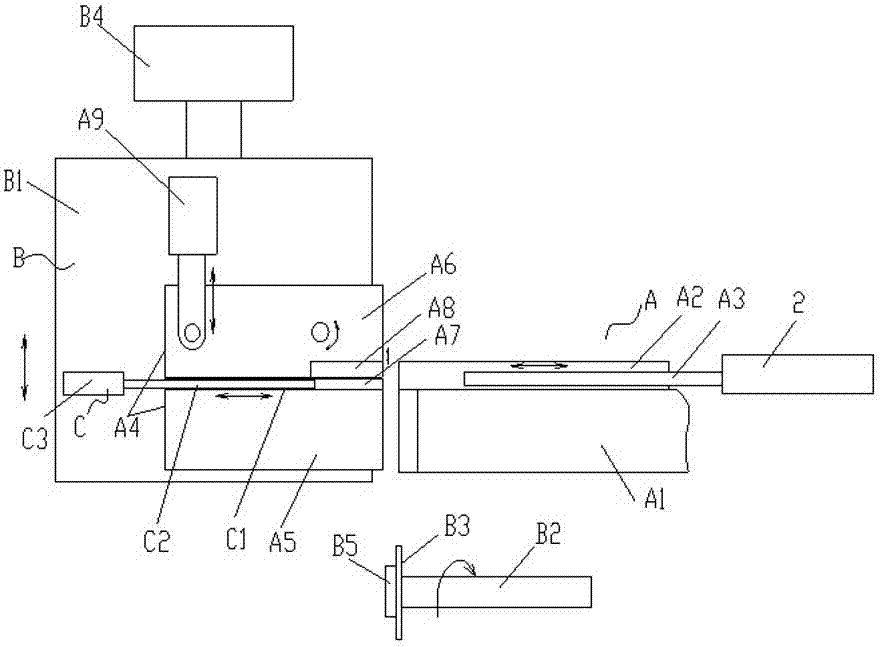

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

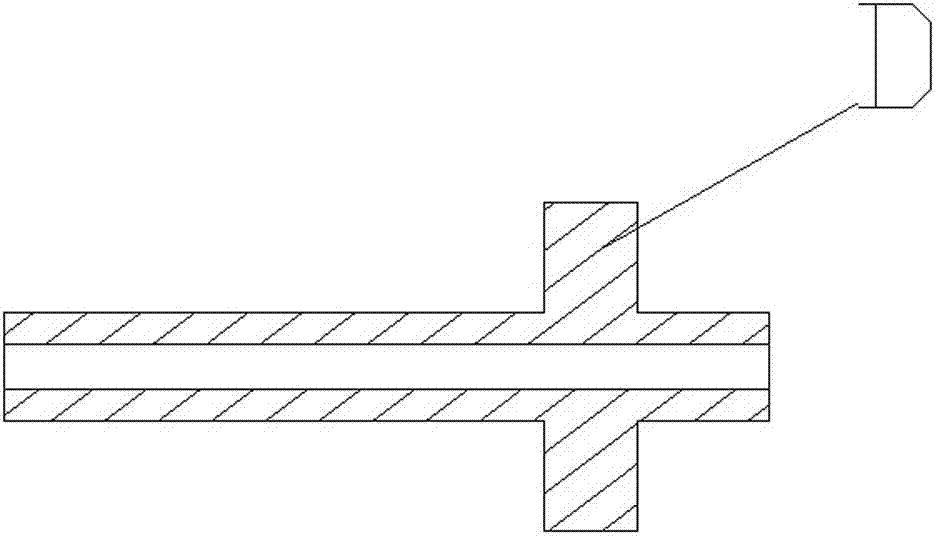

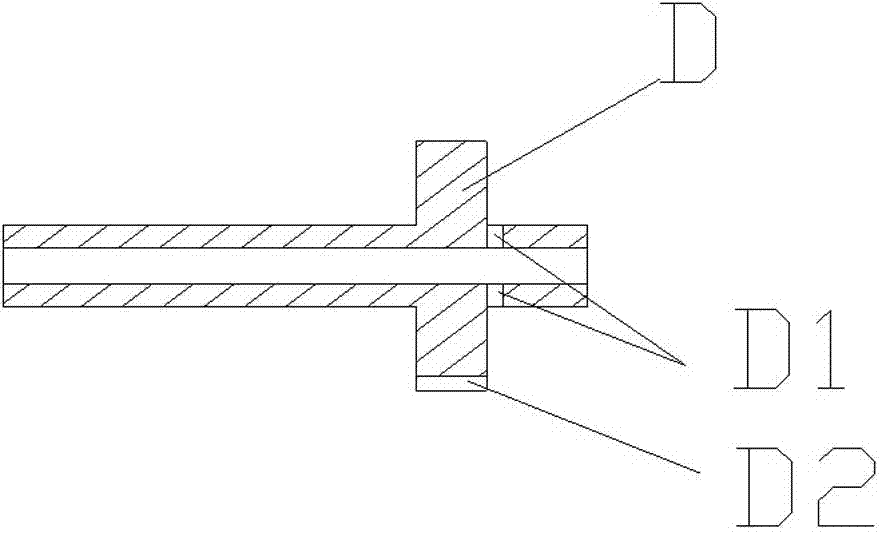

[0022] The tubular workpiece slotting machine of the present invention comprises a tubular workpiece slotting machine feeding mechanism A, a tubular workpiece slotting machine slotting grinding surface mechanism B and a tubular workpiece slotting machine unloading mechanism C, and the tubular workpiece slotting machine feeding mechanism A includes The body A1 and the track A2 arranged on the body A1 for conveying the tubular workpiece, the track A2 is a V-shaped groove, and there is a cover plate on it to prevent the workpiece from falling out. Push rod A3, the front side of the track A2 is provided with a clamping block A4 for clamping the tubular workpiece, the clamping block A4 includes a lower fixed block A5 and an upper movable block A6 that can be raised and lowered relative to the lower fixed block A5, and the lower fixed block ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com