Pressing machine

A press-fitting machine and press-fitting technology, which is applied in the field of assembly equipment, can solve the problems of unreliable press-fitting quality and low production efficiency of engineering steel ring parts, and achieve the effects of being beneficial to manufacturing and assembly, high production efficiency and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

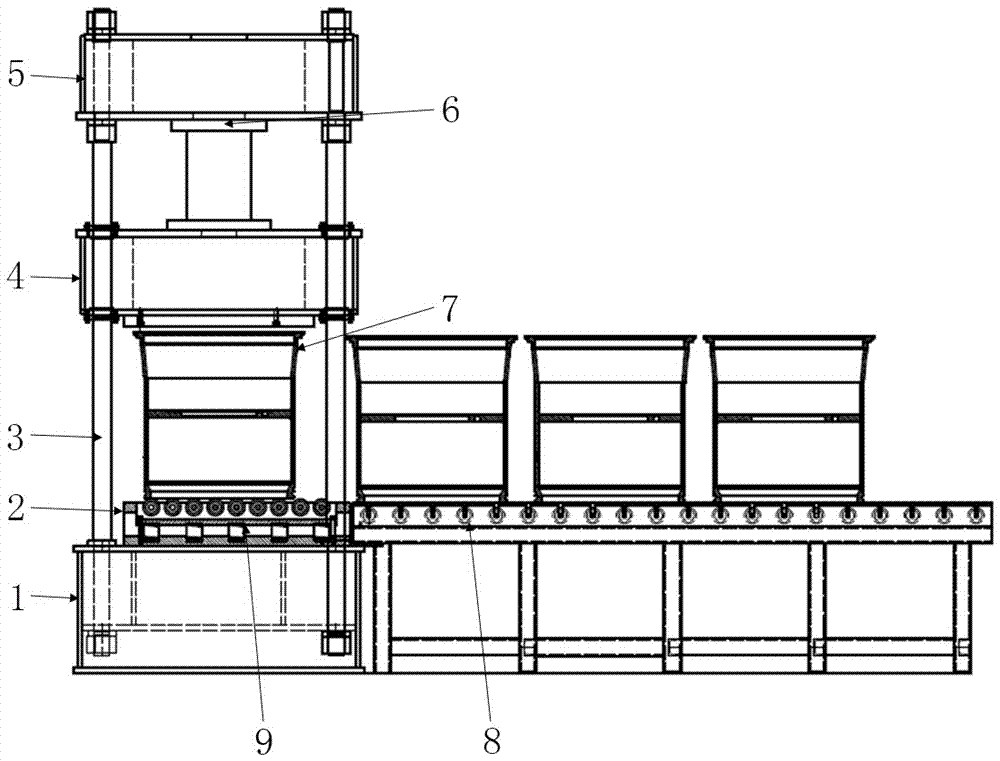

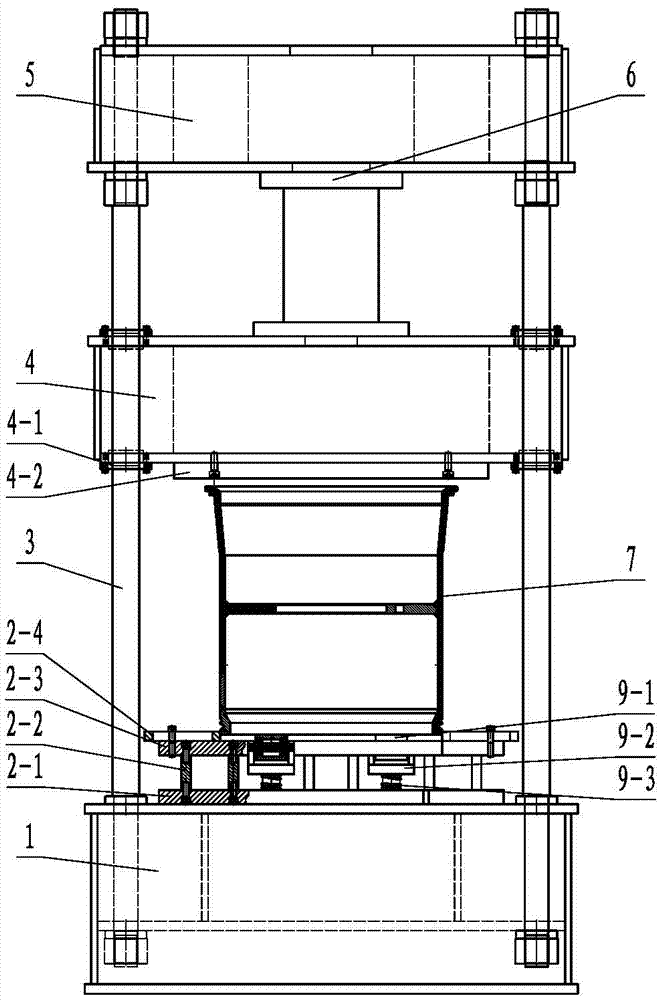

[0022] figure 1 with figure 2 The press installation shown mainly includes a frame, a hydraulic press 6, a positioning tool 2, a press slide 4, an elastic support unit 9 and a conveying roller table 8, and the frame is composed of an upper beam 5, four guide columns 3 and a base 1. , four guide columns 3 are respectively fixed on the four corners of the base 1 by positioning rings and lock nuts, and the upper beam 5 is also fixed on the top of the four guide columns 3 by positioning rings and lock nuts. Between the upper beam 5 and the base 1, there is a press-fit sliding table 4 that is slidably matched with the guide column 3. The base 1, the press-fit sliding table 4 and the upper beam 5 are respectively made of steel plate tailor welding; in order to prevent the press-fit sliding table 4 from Wear and tear, press-fit sliding table 4 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com