Machine enclosure machining assembly line device

A technology of assembly line and casing, applied in the field of assembly line, can solve the problems of increasing processing cost, waste of raw materials, large workload, etc., and achieve the effect of eliminating the operation of replacing the device and simplifying the complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail in conjunction with the accompanying drawings

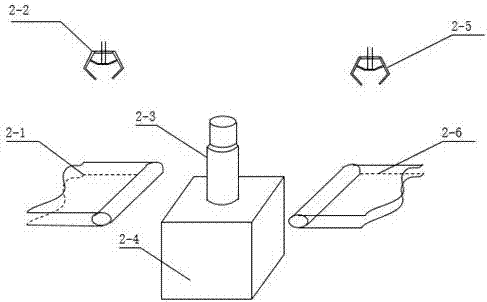

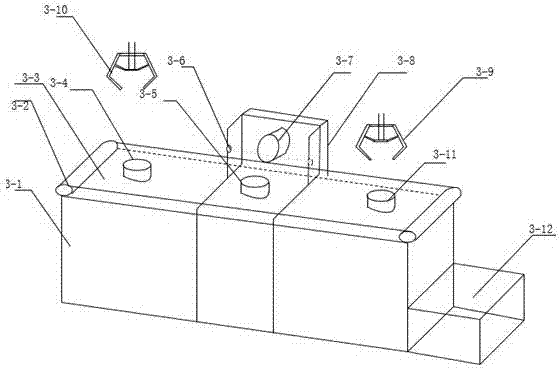

[0017] Such as Figure 7 As shown, a general diagram of a casing processing assembly line device, 0-1 is a rotator controlled by a stepping motor, 0-2 is a cutting device host, linked to a guide rail, and a plc is installed inside; 0-3 is a laser cutter; 0 -4, 0-6 are fixtures connecting each part, 0-8 are shipping fixtures; 0-5 are hole expanders, and 0-7 are punching machines.

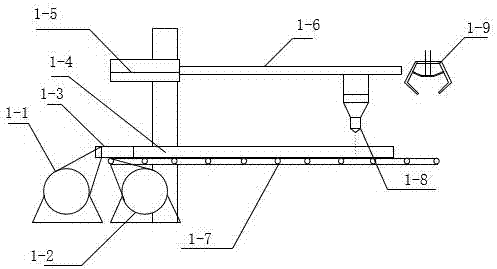

[0018] Such as figure 1 As shown, a casing processing line device: as figure 1 The laser cutting part shown is driven by a stepping motor 1-1, and the connector 1-3 at one end of the fixed aluminum tube 1-4 is rotated around the x-axis, allowing the laser cutter 1-8 to perform rotary cutting at a fixed position. Laser cutting Rotates 360° when the switch is turned on. The laser cutter is installed on the guide rail 1-6 and moves along the y-axis to control the cutting length. It is turned on during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com