Crystal mass bonding device and method

A technology of bonding device and crystal mound, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problems of broken quartz wafers, slow dialysis speed of wax liquid on heating plates, etc. The effect of reducing air residue and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

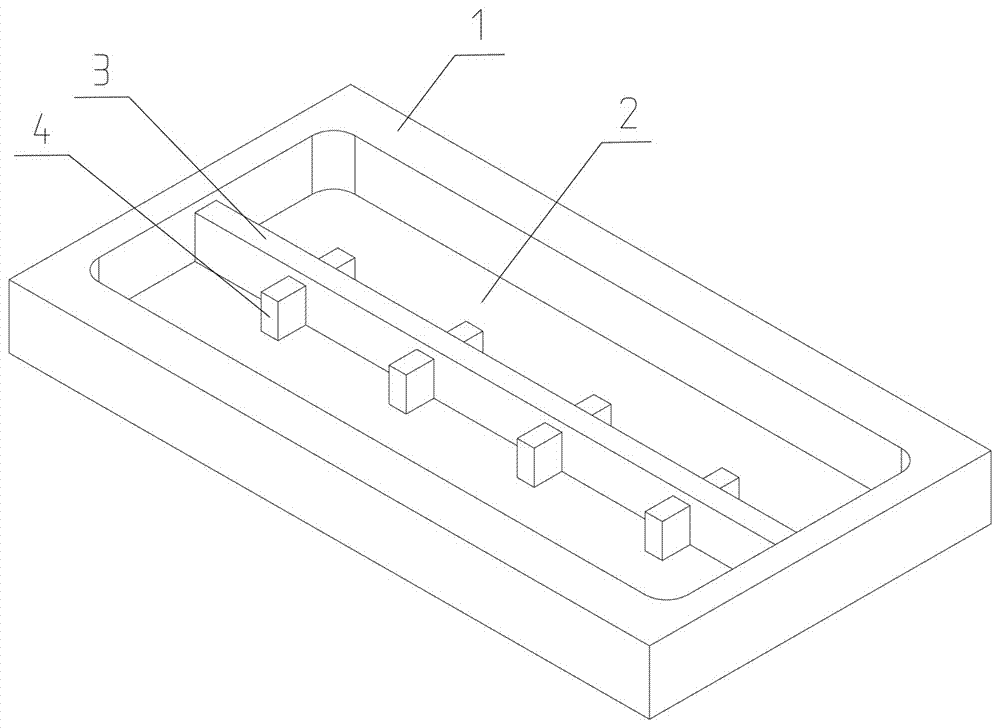

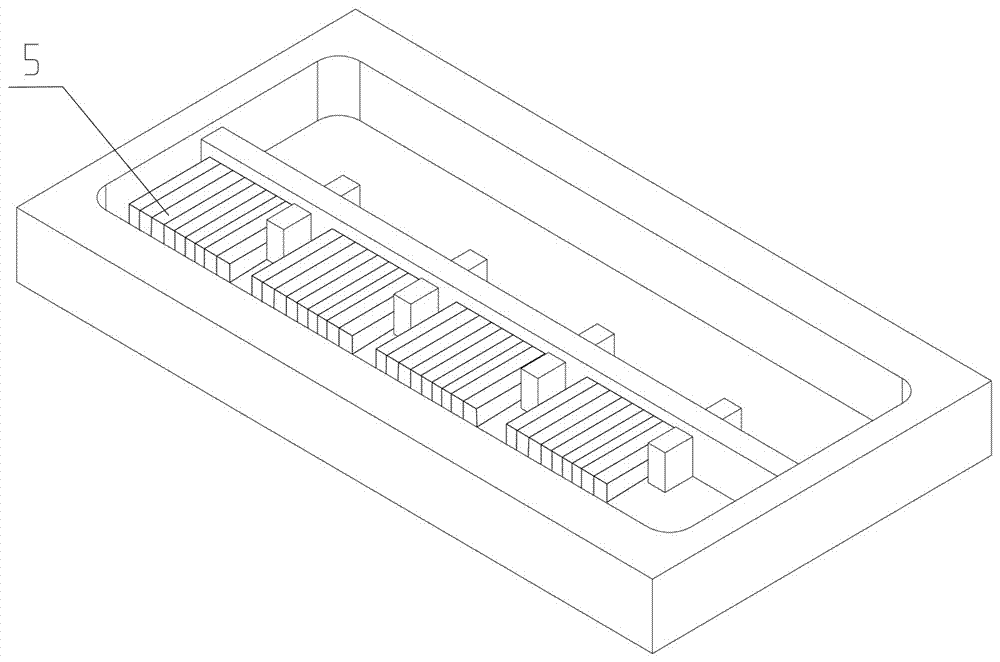

[0031] This embodiment first provides a crystal ingot bonding device, such as figure 1 , figure 2 and image 3 As shown, it includes tweezers 6, a paraffin tank 2 and a partition 3 arranged in the middle of the paraffin tank 2, and four crystal ingot positioning blocks 4 are evenly arranged on both sides of the partition 3 and the crystal One end of the mound positioning block 4 is arranged in the wax penetration tank 2 . Specifically, the assembly state of the crystal ingot bonding device and the crystal ingot 5 is as follows: figure 2 shown. The function of the partition plate 3 is to divide the wax soaking tank 2 into a plurality of self wax soaking tanks.

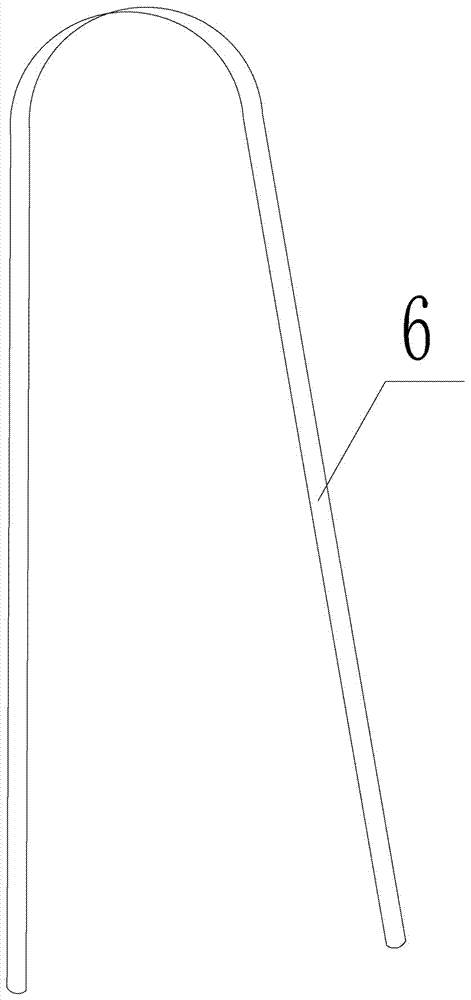

[0032] In order to take out the semi-finished crystal ingot wax from the wax infiltration tank 2 conveniently, the crystal ingot bonding device further includes tweezers 6 for clamping the semi-finished crystal ingot wax infiltration from the wax infiltration tank 2 . Simultaneously, the cross section of describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com