Hopper tipping assembly of dust collection vehicle

A vacuum cleaner and assembly technology, which is applied in the direction of tilted load-carrying vehicles, etc., can solve the problems of unstable center of gravity, materials with telescopic lengths that cannot be dumped cleanly at one time, and easy rollover, etc., to facilitate dumping unloading, reasonable involvement, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

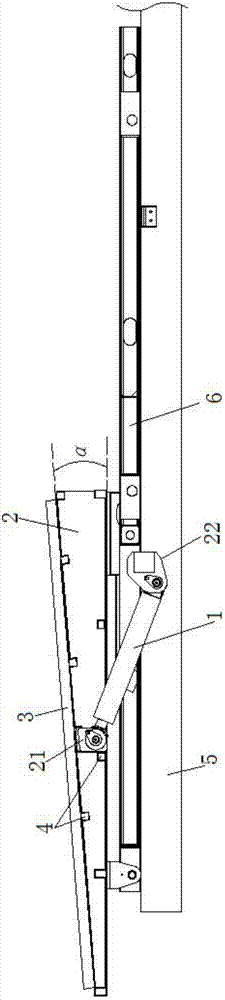

[0029] Example: such as figure 1 As shown, the present embodiment provides a tipping bucket assembly of a dust collection vehicle, a subframe 6 is installed on the vehicle base 5 of the vacuuming vehicle, and the tipping bucket assembly is installed on the subframe 6. Features:

[0030] The dump bucket assembly includes two hydraulic rods 1, two bottom beams 2 and a bottom plate 3;

[0031] The two bottom beams 2 are arranged symmetrically and in parallel, and the upper end faces of the two bottom beams 2 are slopes inclined upward toward the front end of the vacuum truck, and the lower end faces are planes;

[0032] The rear ends of the two bottom beams 2 are respectively hinged to the rear ends of the sub-frame 6;

[0033] The two hydraulic rods 1 are provided in one-to-one correspondence with the two bottom beams 2, and are respectively hinged and fixed on the sub-frame 6 corresponding to the positions of the bottom beams 2, and their telescopic ends are respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com