Rubber hose reel device with volatile gas recycling function

A volatile gas, rubber hose technology, applied in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., can solve the problems of failing to meet the requirements of regulations and technical specifications, unable to play oil and gas, separation, etc., to achieve suitable In the promotion and implementation, improve the efficiency of operation, the effect of easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the recovery of oil vapor during fuel filling at a gas station is taken as an example.

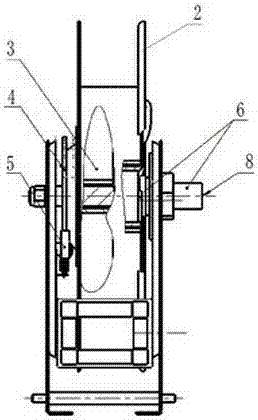

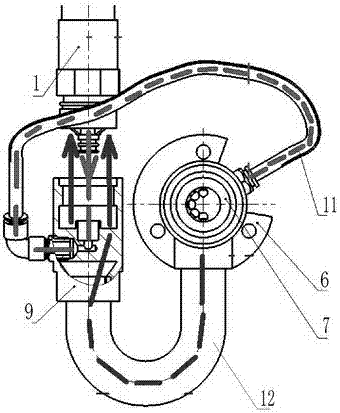

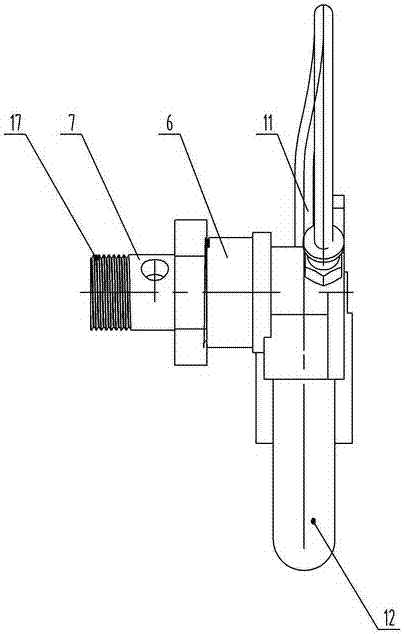

[0031] see Figure 1-8 , in the figure ( figure 2 The direction of the middle arrow indicates the flow direction of gas or liquid), the rubber hose reel device of the present invention includes a rubber hose, a reel 2, a coil spring 3, a limit mechanism composed of a ratchet 4 and a pawl 5, and a valve body, wherein the rubber hose is wound on the reel On the disk, the liquid output port of the hose is connected to the oil gun, and the valve body includes a valve seat 6 and a valve core 7, and the valve core is provided with an oil inlet 8. After the user lifts the gun, stretch the rubber hose and oil gun outward, and the reel rotates accordingly; when it is stretched to the vicinity of the refueling position, the standby pawl snaps into the tooth groove of the ratchet wheel, and the rubber hose is no longer retracted and pre-tensioned by the built-in coil spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com