Dry quenching shaft lining quick overhaul construction method

A construction method and dry quenching furnace technology, applied in coke ovens, petroleum industry, coke cooling and other directions, can solve the problems of long maintenance time of CDQ furnaces, affecting economic benefits, hindering production rhythm, etc., to achieve reasonable repair steps and high quality Safe and reliable, the effect of saving maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The quick overhaul construction method of CDQ furnace lining of the present invention comprises the following steps:

[0041] a. Formulate the construction process for the overhaul of CDQ furnace lining

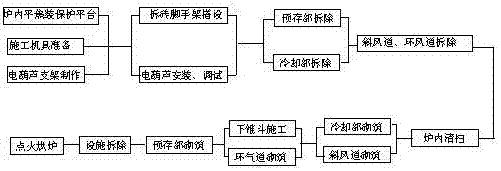

[0042] figure 1 It is a flowchart of quick overhaul of CDQ furnace lining according to the embodiment of the present invention. The CDQ furnace lining overhaul construction process includes the following specific measures:

[0043] 1) Flat coke installation and protection platform in the furnace;

[0044] 2) Set up scaffolding for demolition of bricks:

[0045] 3) Remove the pre-storage part and cooling part;

[0046] 4) Remove the inclined air duct and the surrounding air duct:

[0047] 5) Masonry cooling part and inclined air duct;

[0048] 6) Masonry surrounding air duct and construction lower cone bucket;

[0049] 7) Masonry pre-storage department;

[0050] 8) Facilities dismantled.

[0051] b. Plan the vertical transportation method of materials

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com