Treatment method of cavity beneath road slab of airfield pavement

A panel and void removal technology, which is applied in the field of void treatment at the bottom of the airport aisle panel, can solve problems such as long time required, low flexibility, and incomplete void disposal, and achieve the effect of saving maintenance costs and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] like figure 1 , figure 2 As shown, in order to solve the problem of voiding at the bottom of the slab of the airport aisle, the technical methods used are:

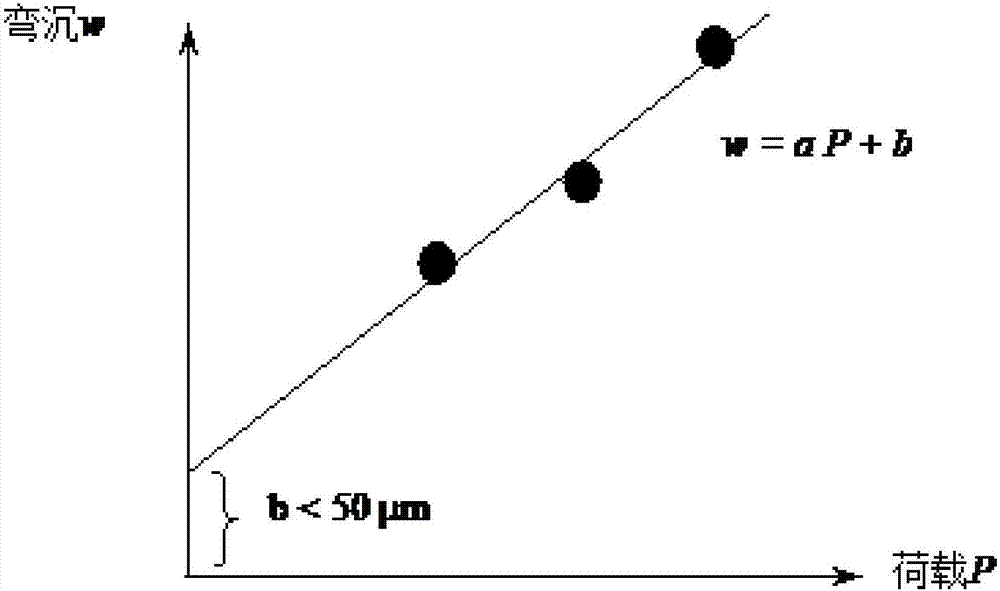

[0023] First of all, it is judged whether the bottom of the road slab is empty, and three different loads are applied to the edge or corner of the road slab by using a heavy-duty drop weight deflection meter to detect the deflection, and establish the correlation between the load and the deflection. When the straight line of the sinking relationship passes the origin or the intercept with the deflection axis is less than 50 μm, the position is considered to be void; otherwise, the position is considered to be void.

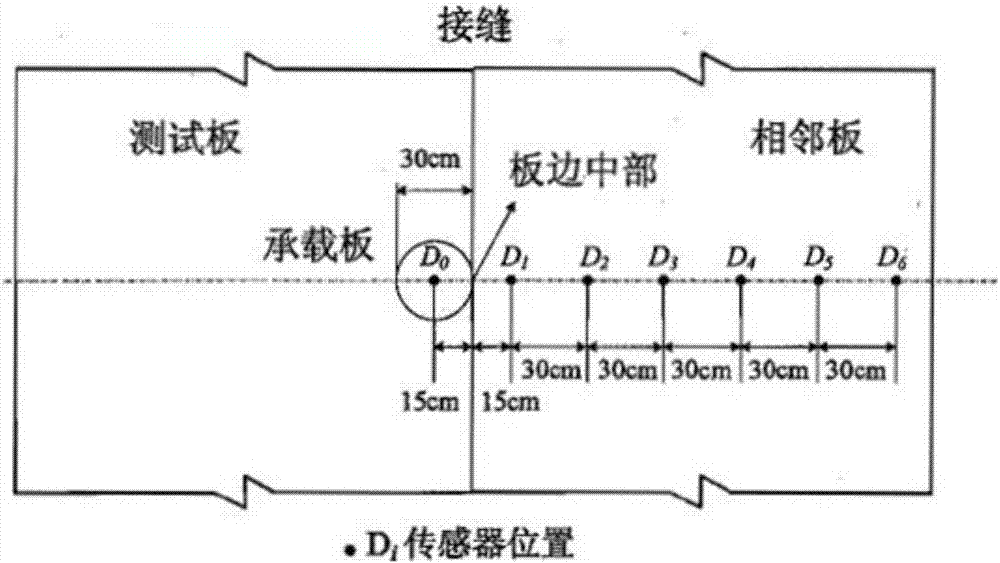

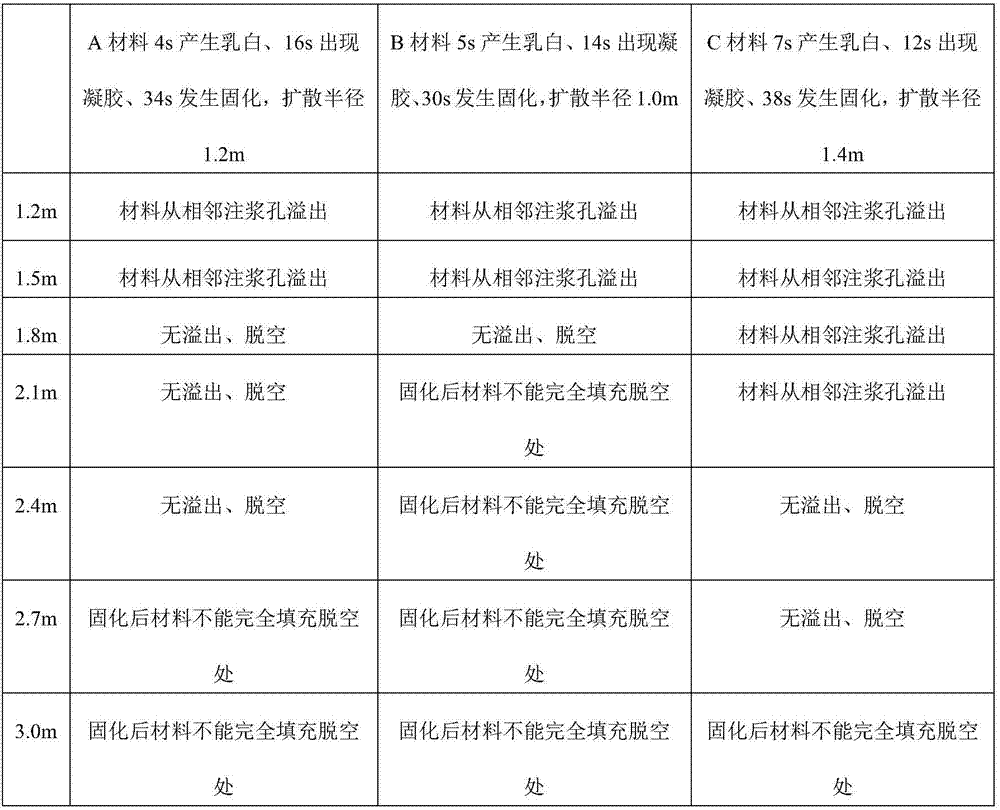

[0024] Then, according to the void situation and the influence of polymer materials, the diameter ranges from 2.4 to 3m, so the grouting positions are arranged at intervals of 1.8 to 2.4m on both sides of the road face plate seam and on the road face plate. The distance of 1.8 to 2.4 meters is based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com