Horizontal splicing system used for assembly type bridge prefabricated pier formworks

A prefabricated and bridge technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of affecting the metal contact ratio between tower sections, time-consuming and laborious, and inconvenient operation of assembly equipment, so as to improve the degree of docking fit, The effect of easy operation and popularization for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

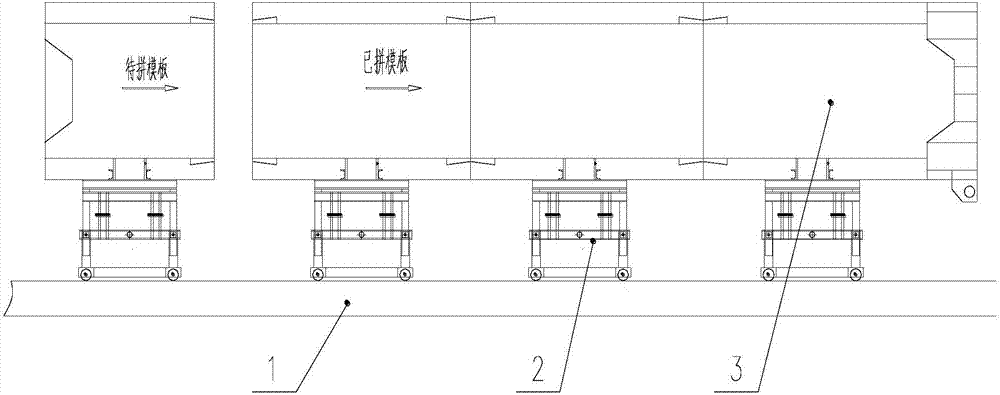

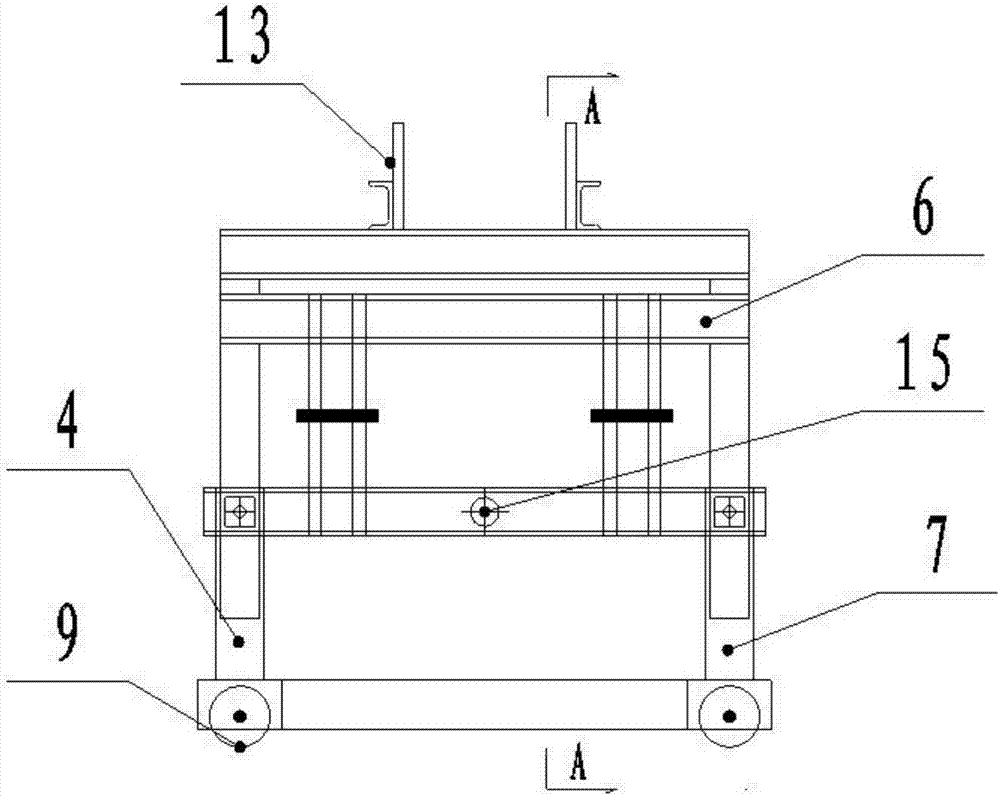

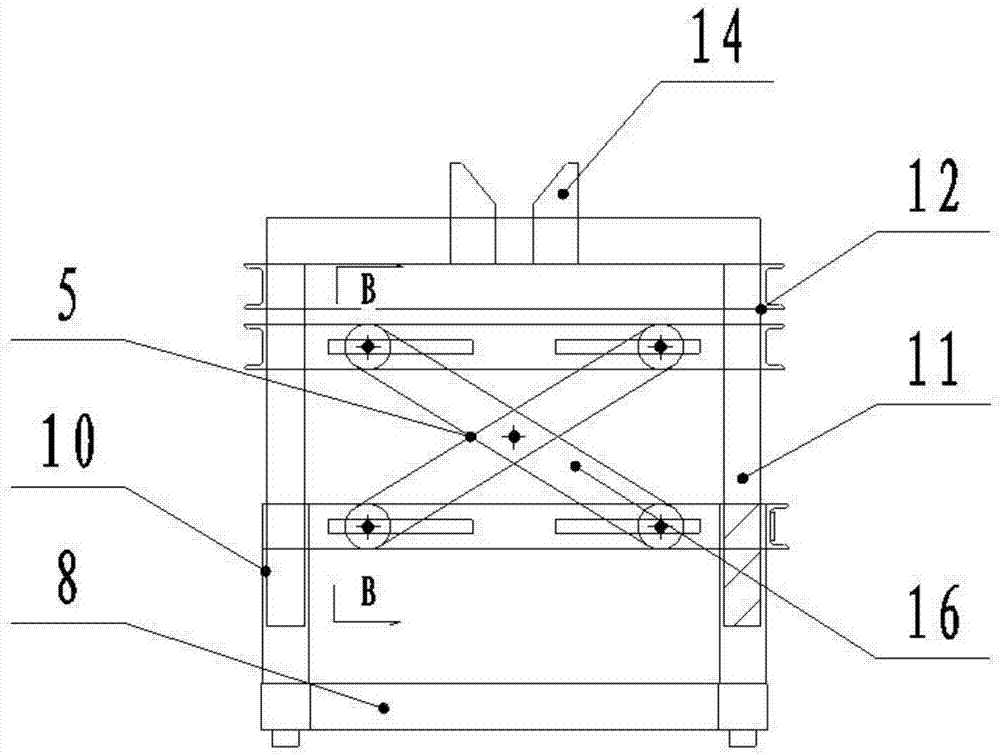

[0027] Such as figure 1 As shown, the present invention is a horizontal assembly system for the prefabricated bridge pier formwork of the prefabricated bridge. 2 (such as figure 1 shown), the assembling trolley 2 moves back and forth on the guide rail 1 by the moving pulley 9 arranged at the bottom, (as Figure 2-3 As shown) the assembled trolley 2 includes a mobile support 4, a lifting adjustment system 5 and a bridge formwork support frame 6, and the bridge formwork support frame 6 is movably arranged on the mobile support 4 to adjust the lift through the lift adjustment system 5. The guide rail 1 is a double guide rail structure. The mobile support 4 includes a supporting frame 8 formed by four supporting legs 7, and the four supporting legs 7 are welded and fixed by reinforcing beams. The four supporting legs 7 can be made of square tube steel, and the lower ends of the supporting legs 7 are provided with movable The pulley 9 and the upper end of the support leg 7 are p...

Embodiment 2

[0034] Such as Figure 1-5 As shown, the present invention is a horizontal assembly system for prefabricated bridge pier templates of prefabricated bridges. On the basis of Embodiment 1, there are two sets of scissor telescopic frames 16 . Pass through, two sets of scissors telescopic frame 16 lower end four joints,; Share a silk sleeve 17 in pairs, thereby control two sets of scissors telescopic frames 16 expansion and contraction by an adjustment lifting screw rod 15. Realizing the lifting support by two sets of scissor telescopic frames 16 can improve the lifting stability of the assembled trolley 2 and also provide bearing capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com