Jet regulator

A technology of jet regulator and flow channel, which is applied in construction, water supply equipment, water resources protection, etc., can solve the problems of high production cost and production assembly cost, low liquid passing rate, single water outlet state, etc., and achieve low production and assembly cost , high liquid passing rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

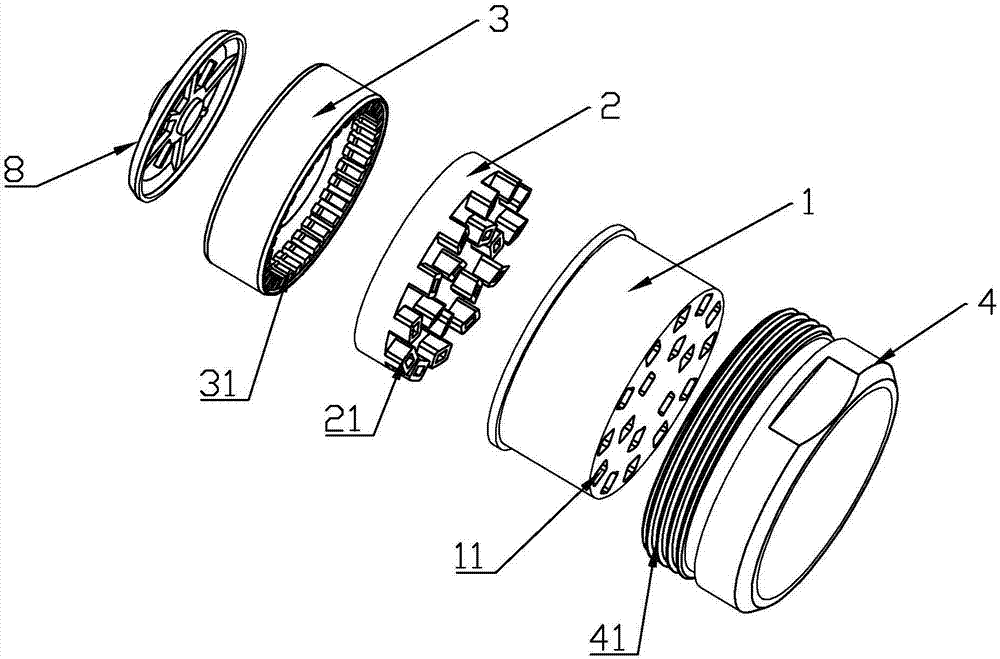

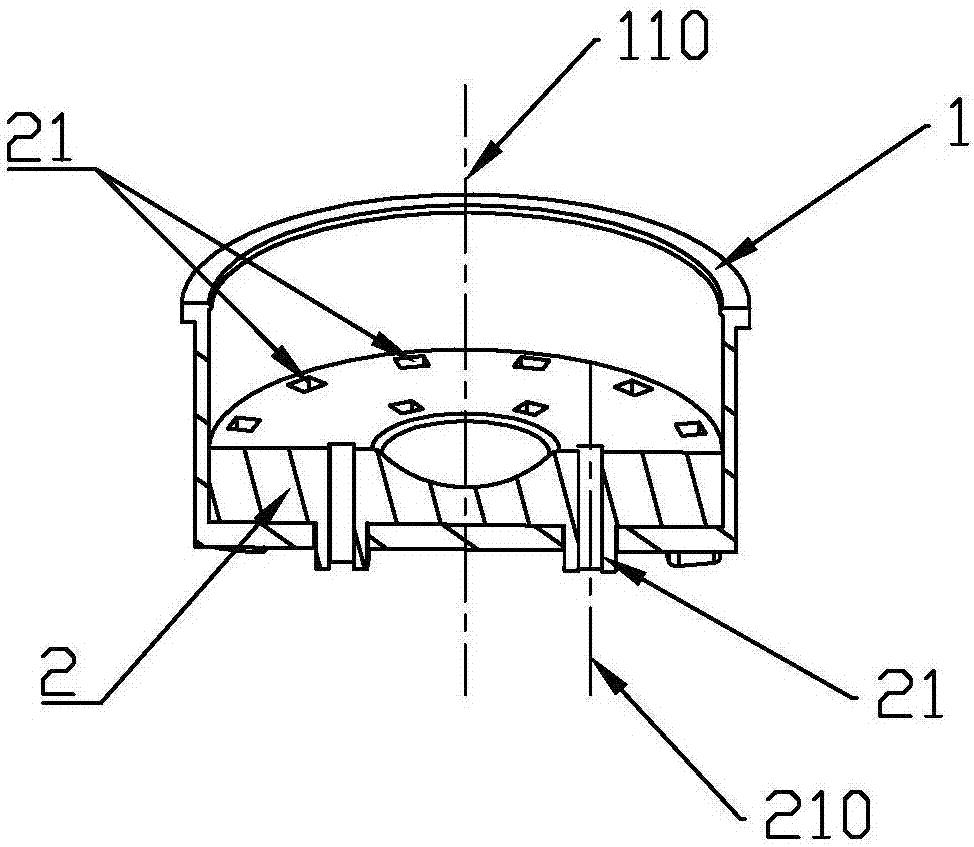

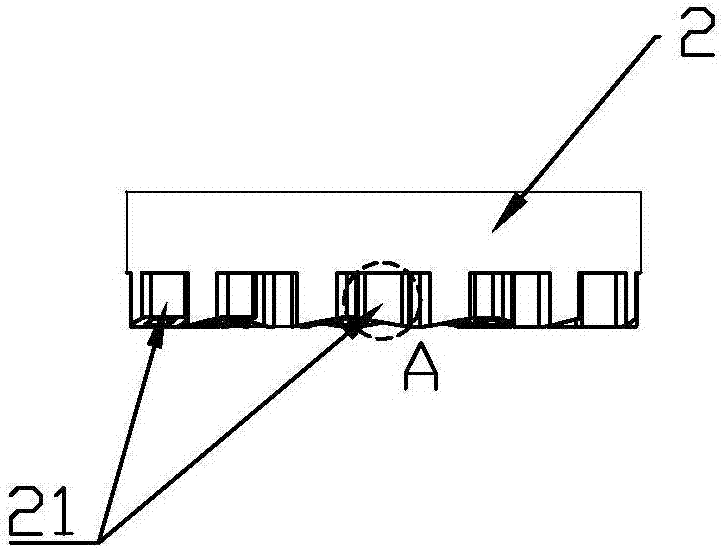

[0048] refer to Figures 1 to 4Shown is a preferred embodiment 1 of the present invention. The jet regulator of this embodiment includes a housing 1 and a water outlet block 2. The housing 1 is provided with a plurality of positioning holes 11 on the water outlet side. The water outlet block 2 A plurality of water outlet channels 21 are provided, and the water outlet channels 21 are correspondingly installed in the positioning holes 11, and the central axis 210 of the water outlet channels is parallel to the longitudinal axis 110 of the housing; A water outlet end surface 22 is provided on the side, and the normal axis 220 of the water outlet end surface 22 forms an angle with the central axis 210 of the water outlet channel 21; the water outlet channel 21 divides the water flow into mutually independent unidirectional jets, respectively defining a flow direction 23 , the outflow direction 23 forms an angle with the central axis 210 of the water outlet channel. In this embodi...

Embodiment 3

[0051] In the third embodiment, preferably, in order to prolong the service life of the fitting shell and the shell, a groove 401 is provided at the position where the inner side of the fitting shell 40 is in contact with the outer circumference of the shell 10, and the groove 401 A wear-resistant washer 402 is installed inside; the center of the water outlet tank 301 is provided with a water baffle 3011, and the setting of the water baffle 301 can effectively control the direction of the water flow, and assist in changing the direction of the jet flow of the water outlet channel 21; in order to adapt to the bathroom of different joints product, the water inlet end of the housing 10 is also provided with an adapter 70 .

[0052] In addition, as a preferred embodiment of the above, the water outlet blocks 2, 20 are made of environmentally friendly food-grade soft materials, which have a certain amount of elastic deformation, and the water outlet blocks 2, 20 can be directly push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com