Plate stretcher stretching cylinder synchronous energy-saving hydraulic complex control system

A compound control and stretching machine technology, which is applied in mechanical equipment, fluid pressure actuators, servo motors, etc., can solve the problems of high cost, low efficiency, and large calorific value of the hydraulic system, and achieve low calorific value and high efficiency , Eliminate the effect of synchronization error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in combination with specific embodiments.

[0012] The two sets of stretching cylinders equipped with displacement sensors in the system of the present invention use a proportional variable pump to realize initial synchronization at the beginning of stretching or return work. When the two sets of stretching cylinders are out of sync during stretching or return, The high-precision and high-response proportional valve control compensation system connected in parallel with the main oil circuits of the two sets of stretching cylinders quickly eliminates synchronization errors.

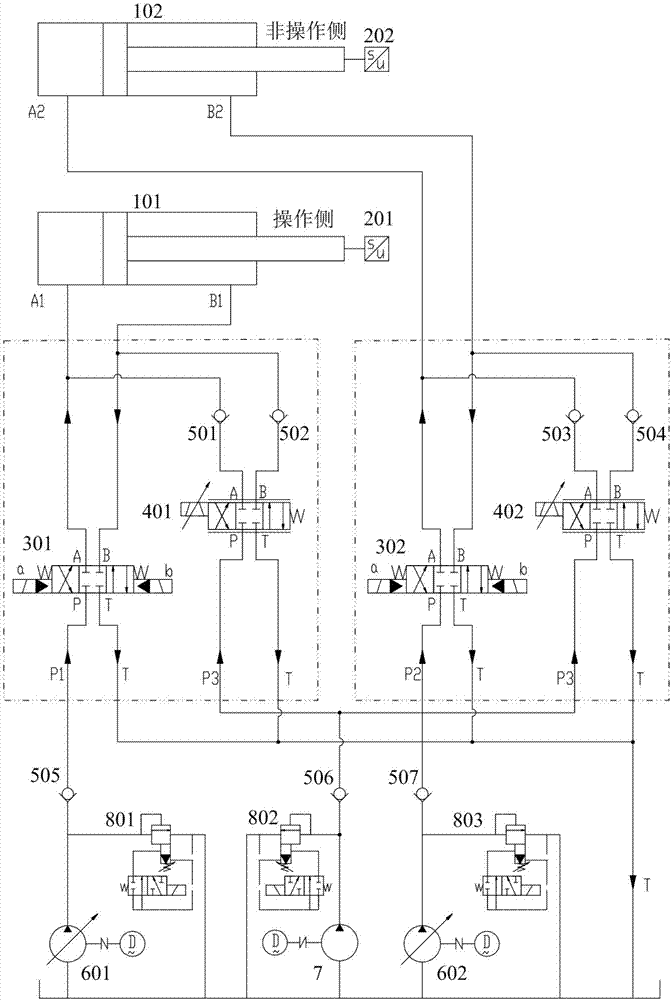

[0013] see figure 1 The present invention relates to a synchronous energy-saving hydraulic composite control system for stretching cylinders of sheet metal stretching machines. The oil ports A1 and B1 of the stretching cylinder 101 on the operating side of the displacement sensor 201 are connected to the first large flow current of the pump con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com