Method and system for production scheduling based on improved particle swarm optimization and heuristic strategy

An improved particle swarm, heuristic technology, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve problems such as unable to obtain global optimal solution, trapped in local optimal, no solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

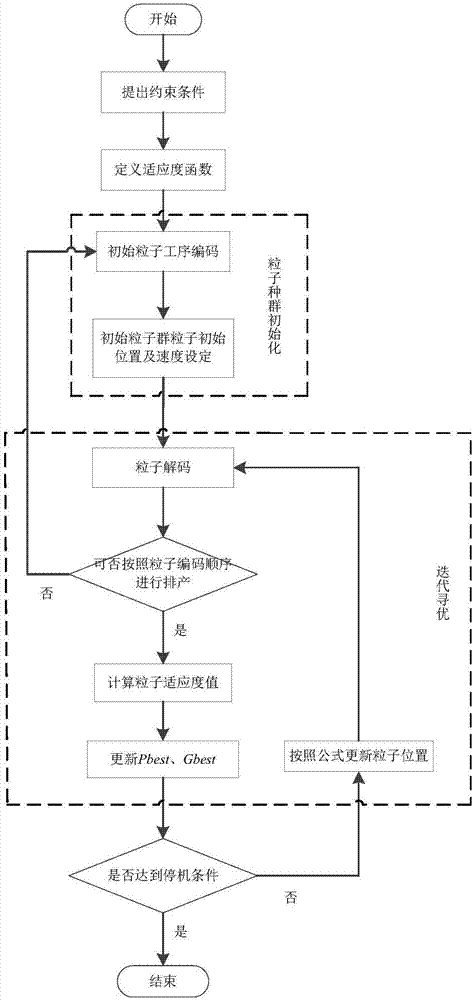

[0066] Such as figure 1 As shown, the present invention is based on the production scheduling method of improved particle swarm and heuristic strategy, comprising the following steps:

[0067] 1. Put forward constraints. By adjusting the machine selected for each task of the work order and the online processing time, a better objective function can be obtained. In the process of selecting the machine and determining the processing time of the work order, the logical relationship of the work order tasks in the work order processing process should be considered. Once the work order task starts, it cannot be interrupted, that is, a single work order task cannot be divided across the unavailable time of the machine. For two processing, a single machine can only process one work order task at the same time, and the machine can only process workpieces withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com