Fault diagnosis method of hydrometallurgy thickener based on credibility

A technology of hydrometallurgy and fault diagnosis, applied in the field of hydrometallurgy, can solve problems such as harsh production environment, frequent changes, and large randomness, and achieve the effect of improving production safety and reducing the incidence of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

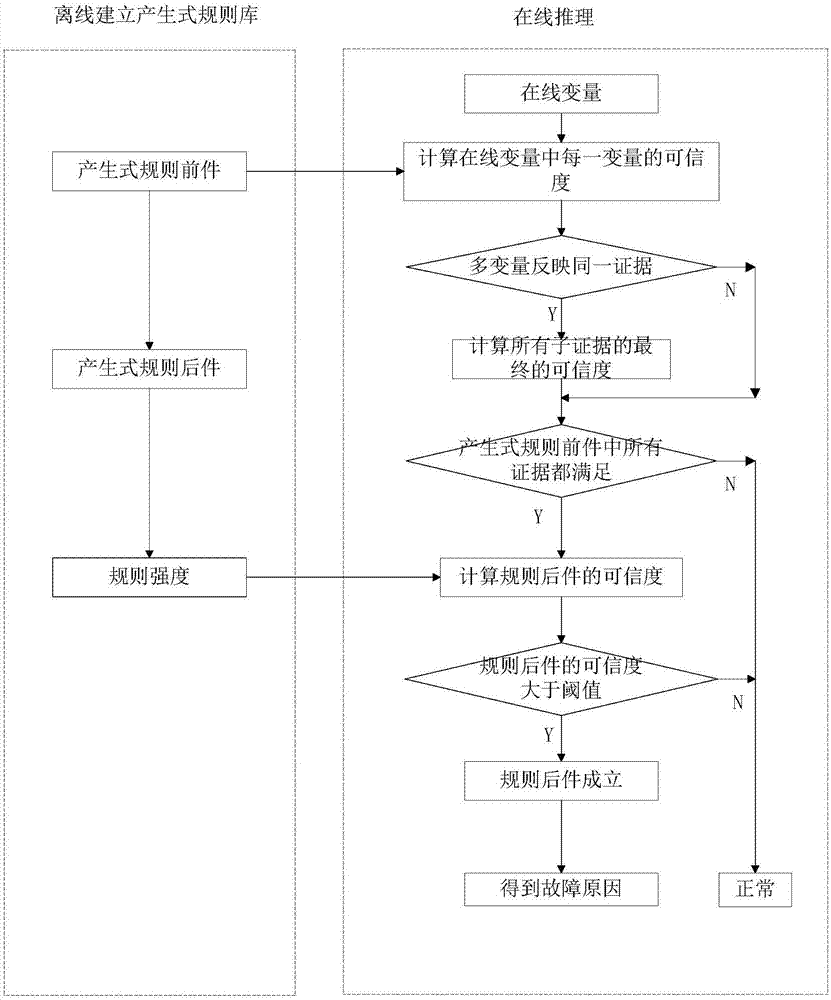

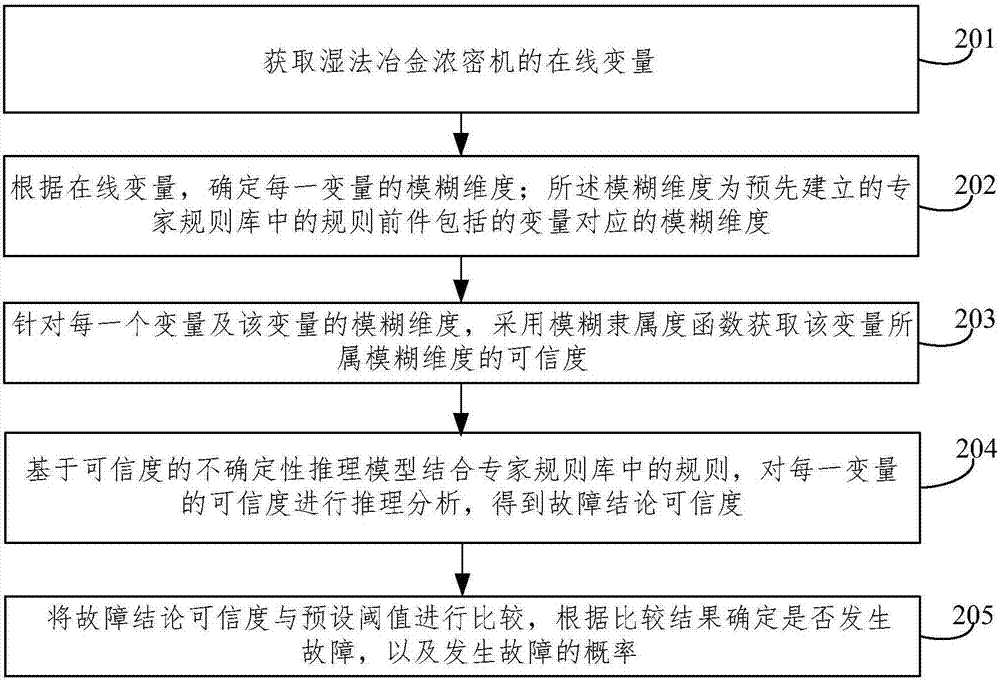

[0069] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

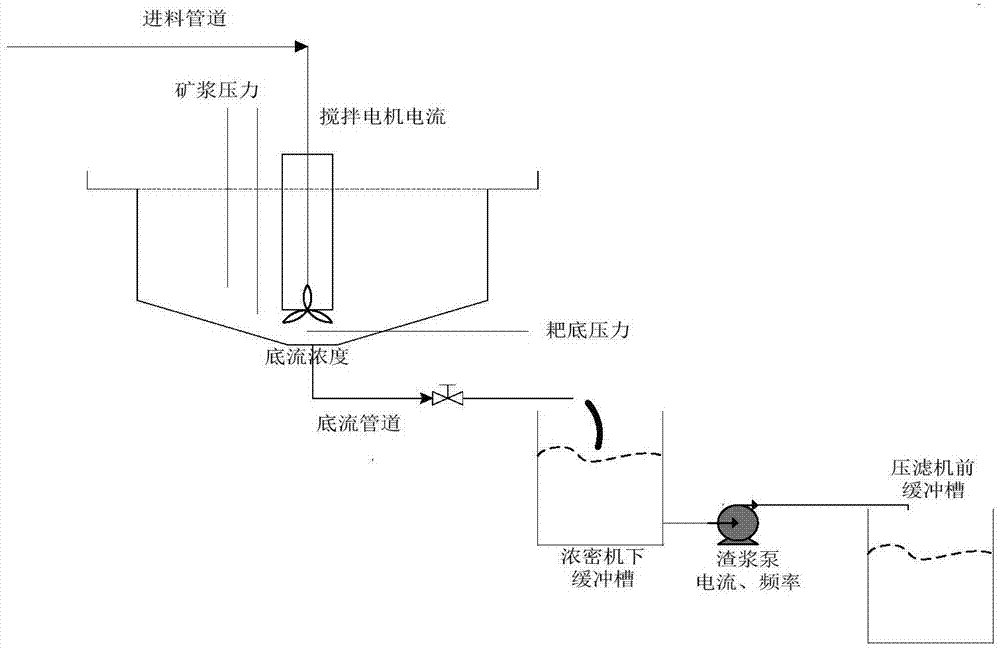

[0070] The device involved in the embodiment of the present invention includes an intelligent fault diagnosis system for a hydrometallurgical thickener, a host computer, a PLC, and an on-site sensing and transmitting part. Among them, the on-site sensing and transmission part includes detection instruments such as concentration, pressure and flow.

[0071] The detection instrument is installed on-site in the hydrometallurgical process. The detection instrument sends the collected signal to the PLC through the Profibus-DP bus. The PLC transmits the collected signal to the host computer through Ethernet at regular intervals. The machine intelligent fault diagnosis system identifies process conditions and diagnoses faults, and provides guidance and suggestions for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com