Mechanical failure state monitoring system based on gray relational analysis and method thereof

A technology of condition monitoring system and grey correlation analysis, applied in manufacturing computing systems, complex mathematical operations, resources, etc., can solve the problems of weak discreteness of correlation value, ignoring differences in factor weights, and non-unique correlation value, etc. The effect of easy promotion, wide application and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

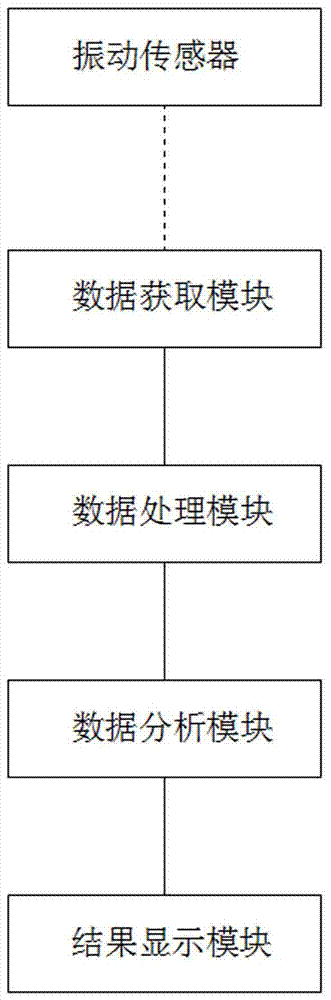

[0030] as attached figure 1 As shown, a mechanical fault status monitoring system based on gray correlation analysis includes:

[0031] The data acquisition module is used to acquire the status data of the machine;

[0032] A data processing module, configured to preprocess the acquired state data, and process the state data into a vector;

[0033] The data analysis module analyzes the obtained vectors through the gray relational analysis method to determine the mechanical failure state;

[0034] The result display module displays the results analyzed by the data analysis module.

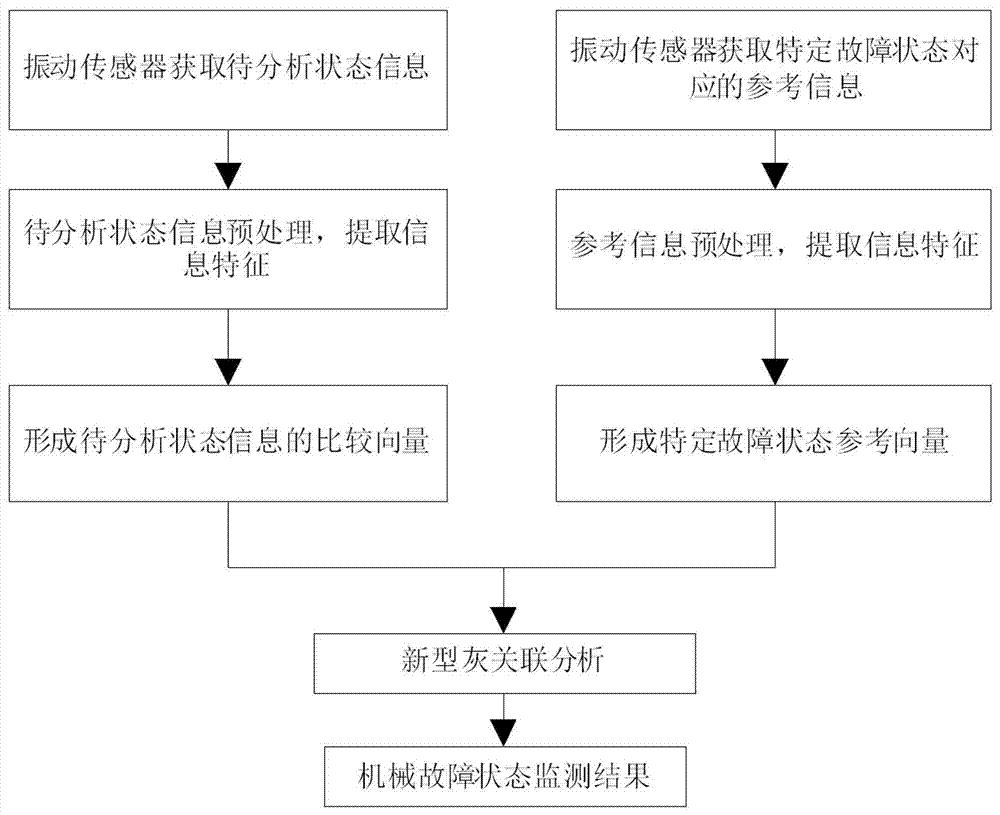

[0035] The state data of the machine includes sample state data and real-time state data. Correspondingly, the data processing module processes the state data into a reference vector in the sample state and a comparison vector in the real-time state, and the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com