Bidirectional steel rail lip polishing machine

A grinding machine and edge fattening technology, which is applied to the grinding frame, the parts of the grinding machine tool, and the machine tool suitable for grinding the edge of the workpiece. Affect the grinding quality and other issues, to achieve the effect of maintaining flexibility and stability, improving grinding efficiency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

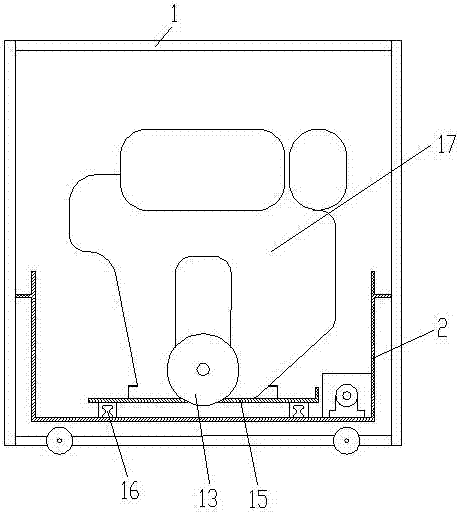

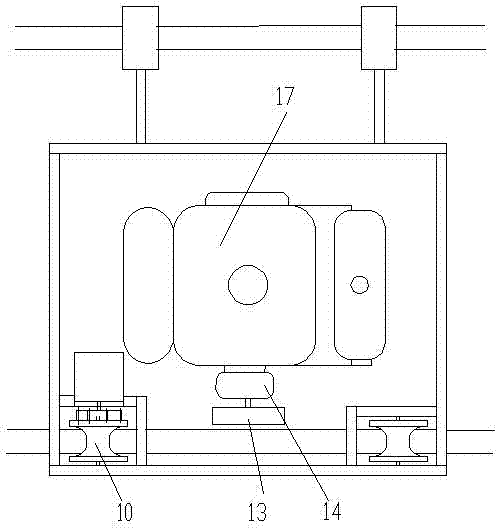

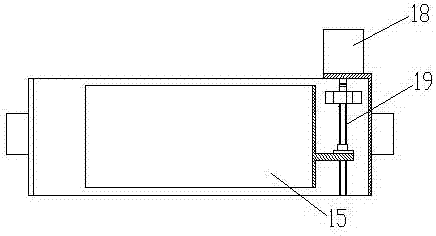

[0041] A two-way rail fat edge grinding machine includes a frame 1, and also includes a horizontal feeding device and a running device, and the horizontal feeding device includes a grinding wheel 13, a gear acceleration box 14, a mobile platform 15, a horizontal slider 16, and a The driving mechanism 17 above the frame 2, the pulse motor 18 and the ball screw pair 19 fixed on the hanger 2, the output shaft of the gear speed-up box 14 is connected with the grinding wheel 13, the input shaft is connected with the driving mechanism 17, and the ball screw Vice 19 is connected with pulse motor 18 and mobile platform 15 respectively, and horizontal slider 16 is slidably connected on the hanger 2, and mobile platform 15 is fixedly connected with horizontal slider 16, and driving mechanism 17 is fixed on mobile platform 15; It includes a driving gear 8, a driven gear 9, a traveling wheel 10, a roller 11 and a motor 12 arranged on the frame 1. The driving gear 8 is connected to the moto...

Embodiment 2

[0044] A two-way rail fat edge grinding machine includes a frame 1, and also includes a horizontal feeding device and a running device, and the horizontal feeding device includes a grinding wheel 13, a gear acceleration box 14, a mobile platform 15, a horizontal slider 16, and a The driving mechanism 17 above the frame 2, the pulse motor 18 and the ball screw pair 19 fixed on the hanger 2, the output shaft of the gear speed-up box 14 is connected with the grinding wheel 13, the input shaft is connected with the driving mechanism 17, and the ball screw Vice 19 is connected with pulse motor 18 and mobile platform 15 respectively, and horizontal slider 16 is slidably connected on the hanger 2, and mobile platform 15 is fixedly connected with horizontal slider 16, and driving mechanism 17 is fixed on mobile platform 15; It includes a driving gear 8, a driven gear 9, a traveling wheel 10, a roller 11 and a motor 12 arranged on the frame 1. The driving gear 8 is connected to the moto...

Embodiment 3

[0052] A two-way rail fat edge grinding machine includes a frame 1, and also includes a horizontal feeding device and a running device, and the horizontal feeding device includes a grinding wheel 13, a gear acceleration box 14, a mobile platform 15, a horizontal slider 16, and a The driving mechanism 17 above the frame 2, the pulse motor 18 and the ball screw pair 19 fixed on the hanger 2, the output shaft of the gear speed-up box 14 is connected with the grinding wheel 13, the input shaft is connected with the driving mechanism 17, and the ball screw Vice 19 is connected with pulse motor 18 and mobile platform 15 respectively, and horizontal slider 16 is slidably connected on the hanger 2, and mobile platform 15 is fixedly connected with horizontal slider 16, and driving mechanism 17 is fixed on mobile platform 15; It includes a driving gear 8, a driven gear 9, a traveling wheel 10, a roller 11 and a motor 12 arranged on the frame 1. The driving gear 8 is connected to the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com