Cableway traction inspection robot system

An inspection robot and robot technology, which is applied to manipulators, manufacturing tools, etc., can solve the problems of function problems, high maintenance costs, and low convenience, and achieve the effects of stable operation, convenient maintenance, and easy disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

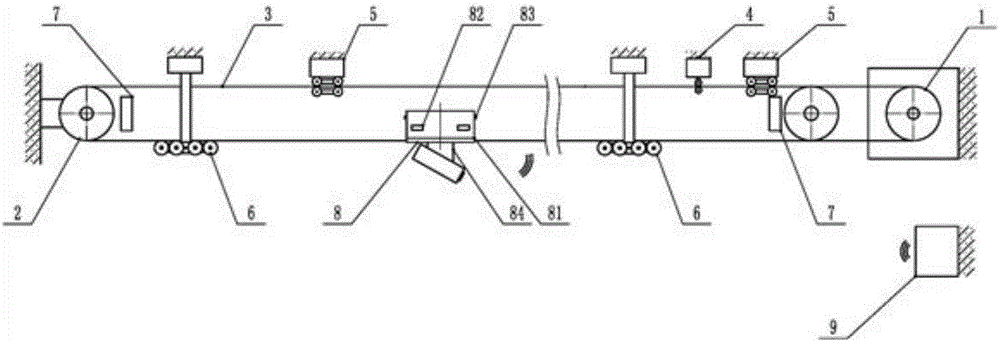

[0033] A cableway traction inspection robot system, such as figure 1 and 2 As shown, it includes a cableway traction motion system, a robot body and a remote control management system 9 .

[0034] Cableway traction motion system includes power system device module 1, fixing device module 2, guide rope 3, encoder device module 4, tension and tension adjustment device module 5, lower support device module 6, turning guide module, charging and buffer device module 7.

[0035] The power system device module 1, the fixing device module 2 and the guide cable 3 constitute the main body of the cableway traction motion system. Cableways generally use metal materials or non-metal composite materials or non-metal materials for robot walking, requiring strong strength, load-bearing and robot matching;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com