Automatic doffer control system with vision

A control system and doffer technology, applied in textiles and papermaking, etc., can solve the problems of increasing factory production costs, failures, and easy fatigue, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

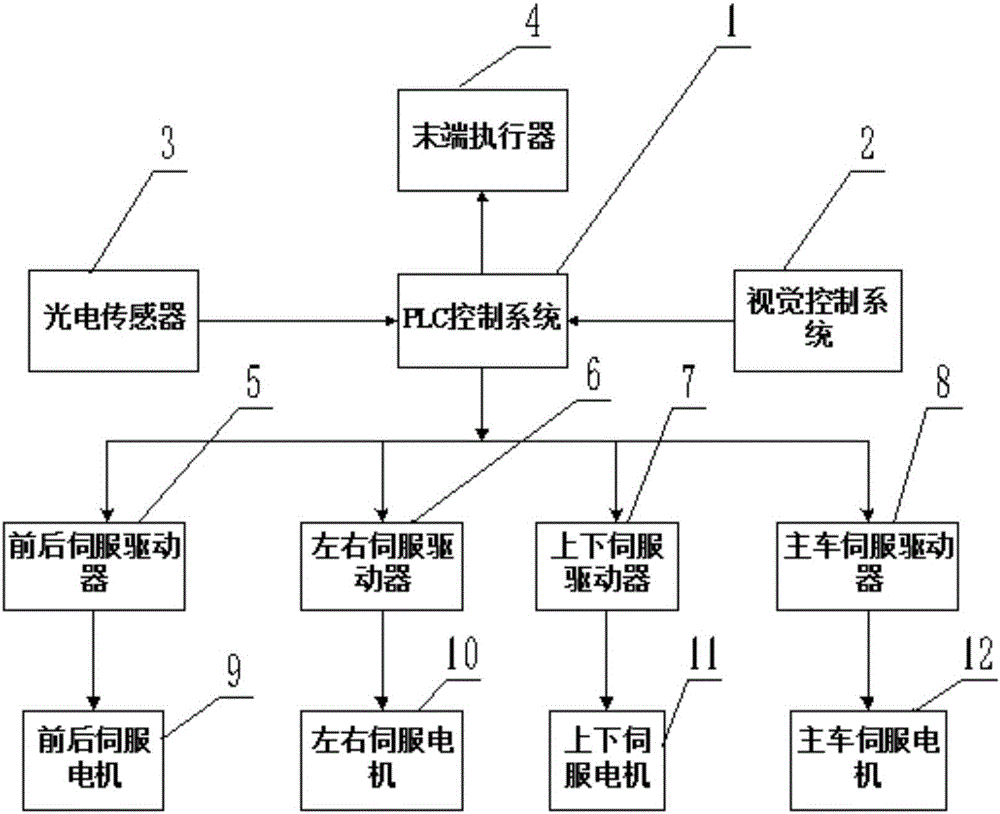

[0020] Please refer to figure 1 , the embodiment of the present invention provides an automatic doffing machine control system with vision, including PLC control system 1, end effector 4, photoelectric sensor 3, vision control system 2, front and rear servo drivers 5, left and right servo drivers 6, Up and down servo driver 7, main car servo driver 8, front and rear servo motor 9, left and right servo motor 10, up and down servo motor 11 and main car servo motor 12.

[0021] The main vehicle servo motor 12 is responsible for the linear motion of the doffing machine along the spinning machine, the front and rear servo motors 9, the left and right servo motors 10, and the up and down servo motors 11 are responsible for the three-dimensional movement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com