Zero leakage hydraulic lock

A technology of hydraulic lock and zero leakage, applied in the field of hydraulic components, can solve the problems of inability to meet the use requirements, low reliability index, damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] First of all, it needs to be explained that the orientation words such as front, back, left, right, up, and down in the present invention are only described according to the accompanying drawings, so as to be easy to understand, and are not intended to describe the technical solutions of the present invention and the scope of protection claimed. limit.

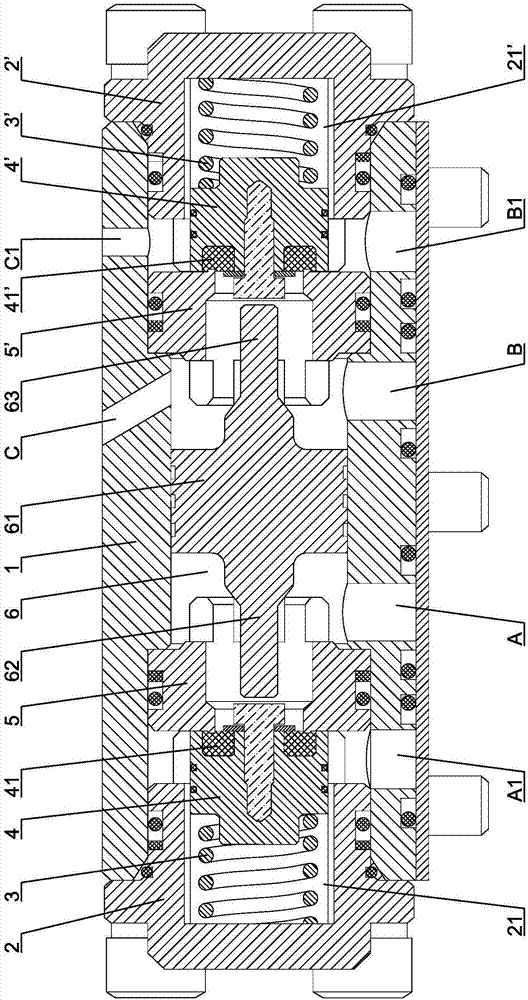

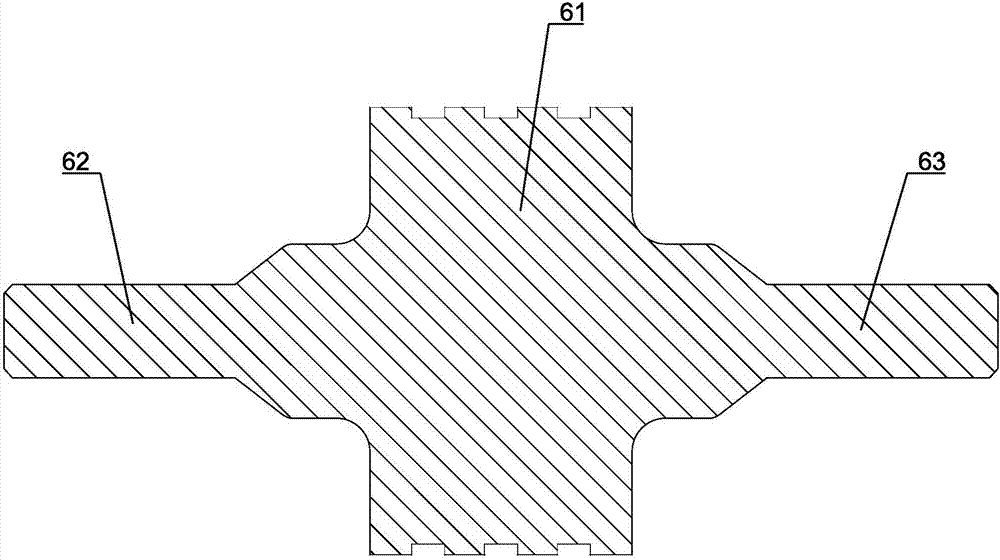

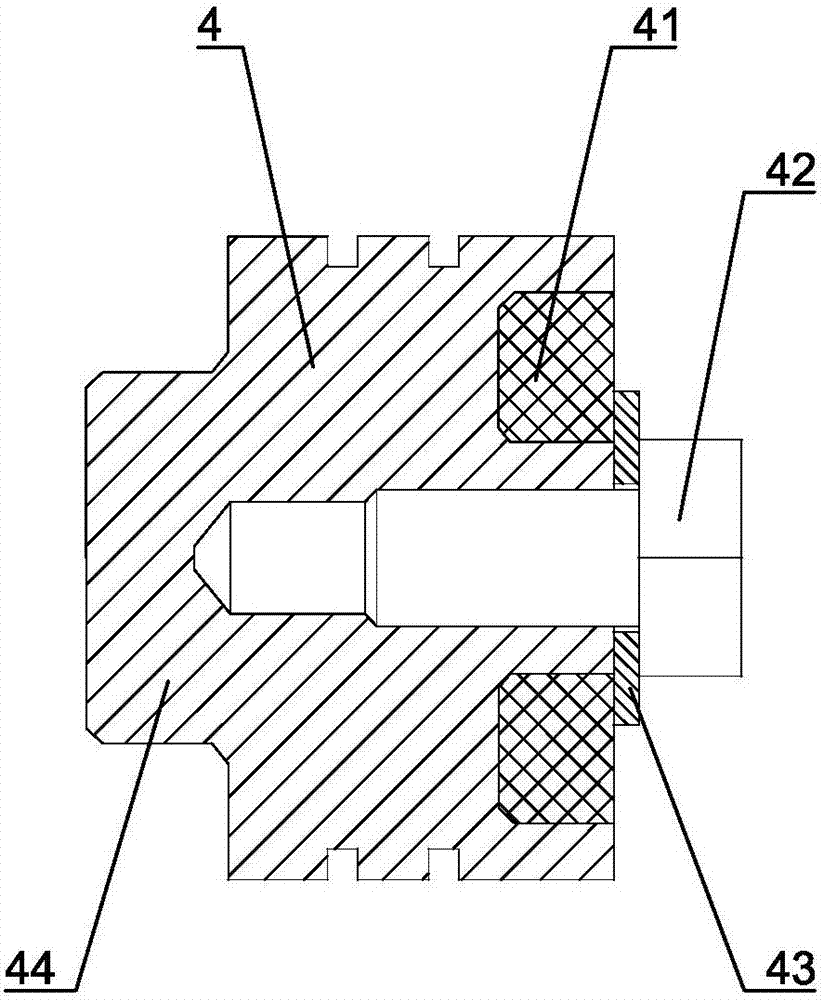

[0023] Such as Figure 1 to Figure 6Shown is a specific embodiment of a zero-leakage hydraulic lock of the present invention, including a cylindrical valve body 1 and a left end cover 2 and a right end cover 2' correspondingly fixed to the left and right ends of the valve body 1. Oil port A, oil port A1, oil port B and oil port B1 are respectively arranged on the valve body 1 . A first groove 21 is provided in the middle of the right end face of the left end cover 2, and a left spring 3 and a left valve 4 are arranged in the first groove 21 from left to right, and a first soft sealing ring 41 is embedded in the right e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com