Cleaning device for plate heat exchanger

A technology for plate heat exchangers and cleaning devices, which is applied in the direction of cleaning heat transfer devices, vibration cleaning, lighting and heating equipment, etc., which can solve problems such as equipment corrosion, increased circulation resistance, and waste of heat energy, so as to prolong the service life and improve Excellent heat exchange efficiency and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

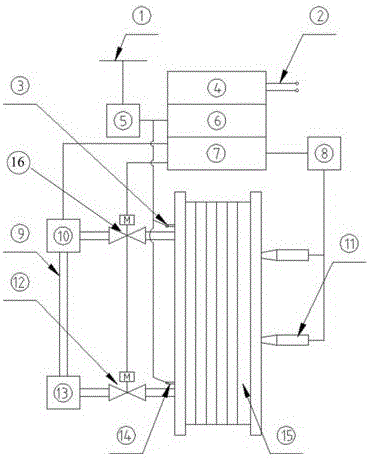

[0006] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the above-mentioned and other purposes, features and advantages of the present invention will be clearer. Such as figure 1As shown, a plate heat exchanger cleaning device includes a plate heat exchanger 15, a reaction kettle 8, an ultrasonic reaction device 10, a control system 7, a first valve 12, a circulation pipe 9, a display operating system 1, a communication module 5, Control device 4, and buffer expander 13. The ultrasonic reaction device 10 is connected to the second valve 16 through a pipeline, the second valve 16 is connected to the plate heat exchanger 15, the heat exchanger body 15 is connected to the first valve 12 through a pipeline, and the first valve 12 is connected to the buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com