Industrial data driving prediction control method based on subspace identification

A technology of subspace identification and industrial data, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of low product yield, low control accuracy, high consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with embodiment.

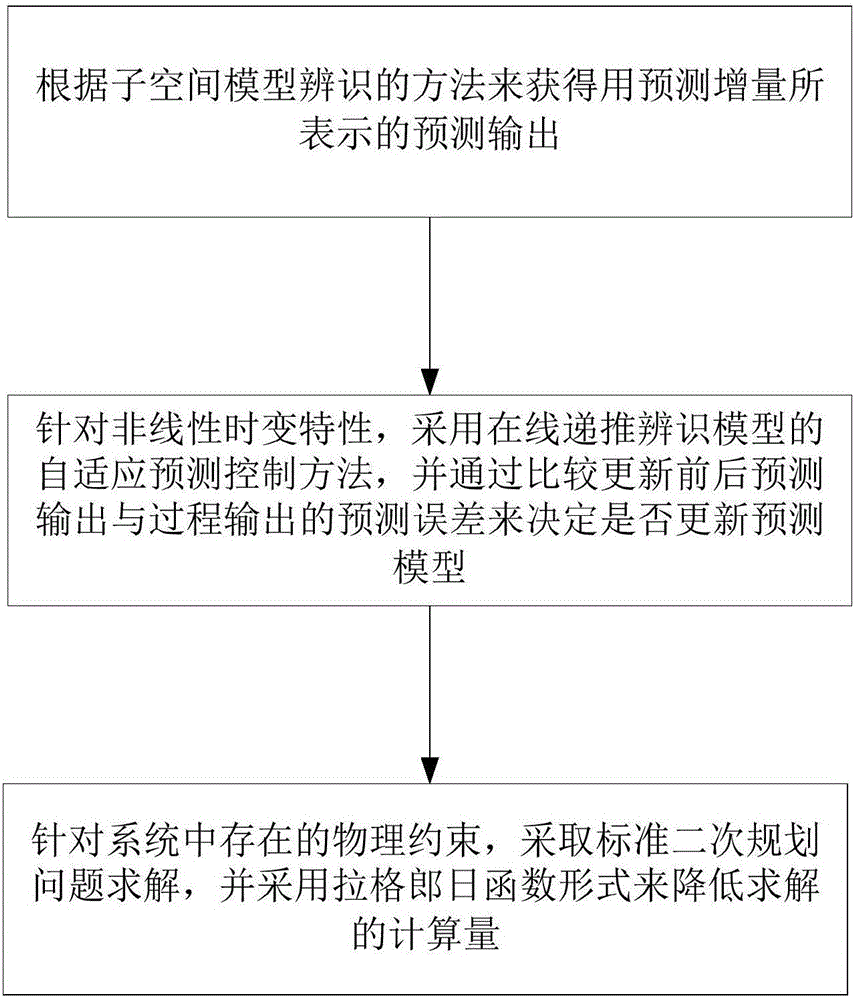

[0065] In this embodiment, the industrial data-driven predictive control method based on subspace identification includes the following steps:

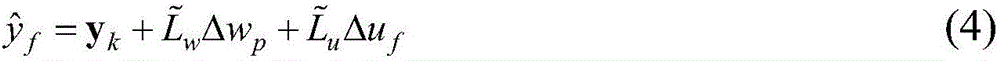

[0066] 1) Obtaining the output of the prediction model; consider the following discrete linear time-invariant system:

[0067]

[0068] where input u k ∈ R m , output y k ∈ R l , state x k ∈ R n . noise sequence {e k} is zero-mean Gaussian white noise, and its variance matrix is A, B, C, D, K are matrices of corresponding dimensions.

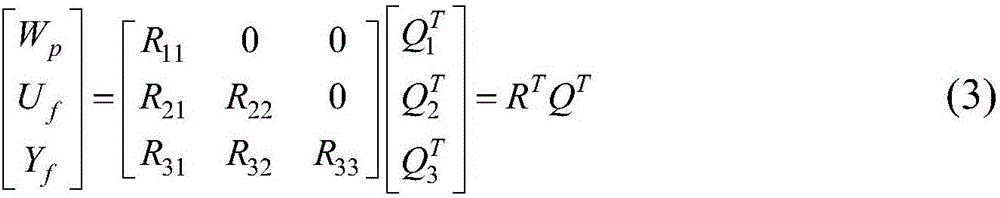

[0069] According to the input u k (k=1,2,...,2i+j-1) data to establish i row j column Hankel matrix U p and U f :

[0070]

[0071]

[0072] Among them, p and f represent "past" and "future" respectively; similarly, output y can be based on k The data to build the Hankel matrix Y p and Y f , according to the measurement noise e k The data to build the Hankel matrix E p and E f .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com