Upwelling cultivation facility of land-based shellfish

A base type and shellfish technology, which is applied in the field of land-based shellfish upwelling culture equipment, can solve the problems of increased human workload, local accumulation of shellfish seedlings, and uneven water flow in the screen, so as to solve the problem of feeding Effects of unevenness, avoidance of biofouling, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

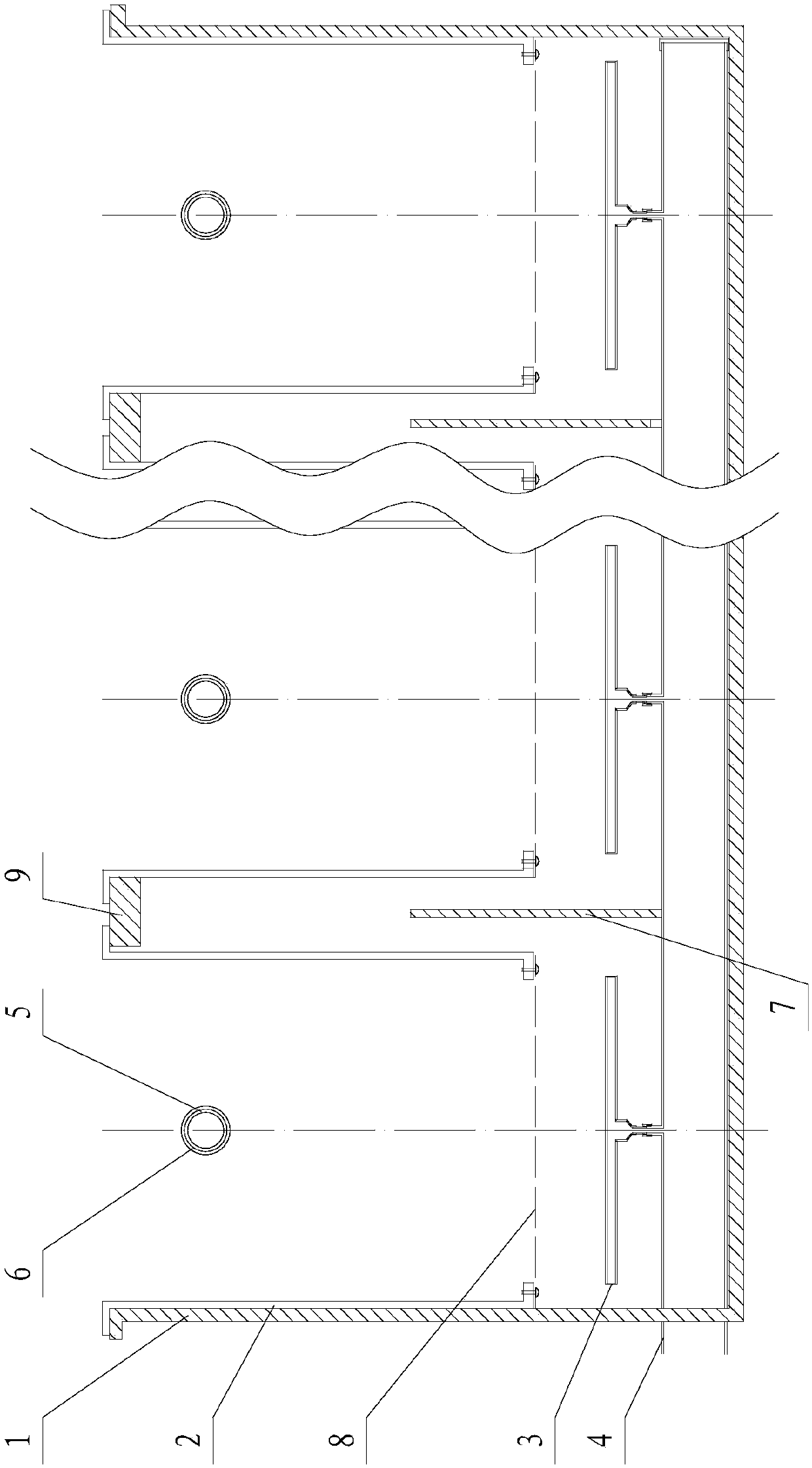

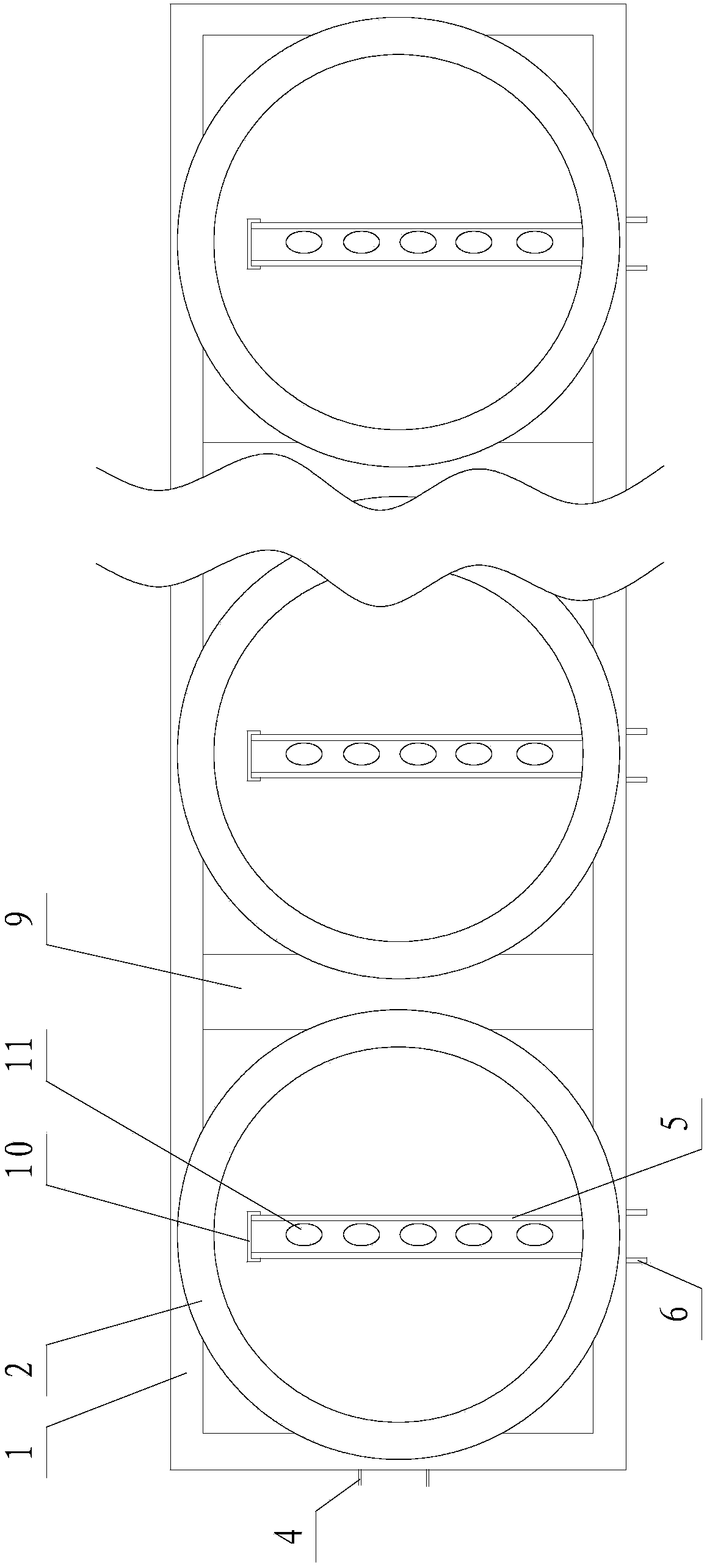

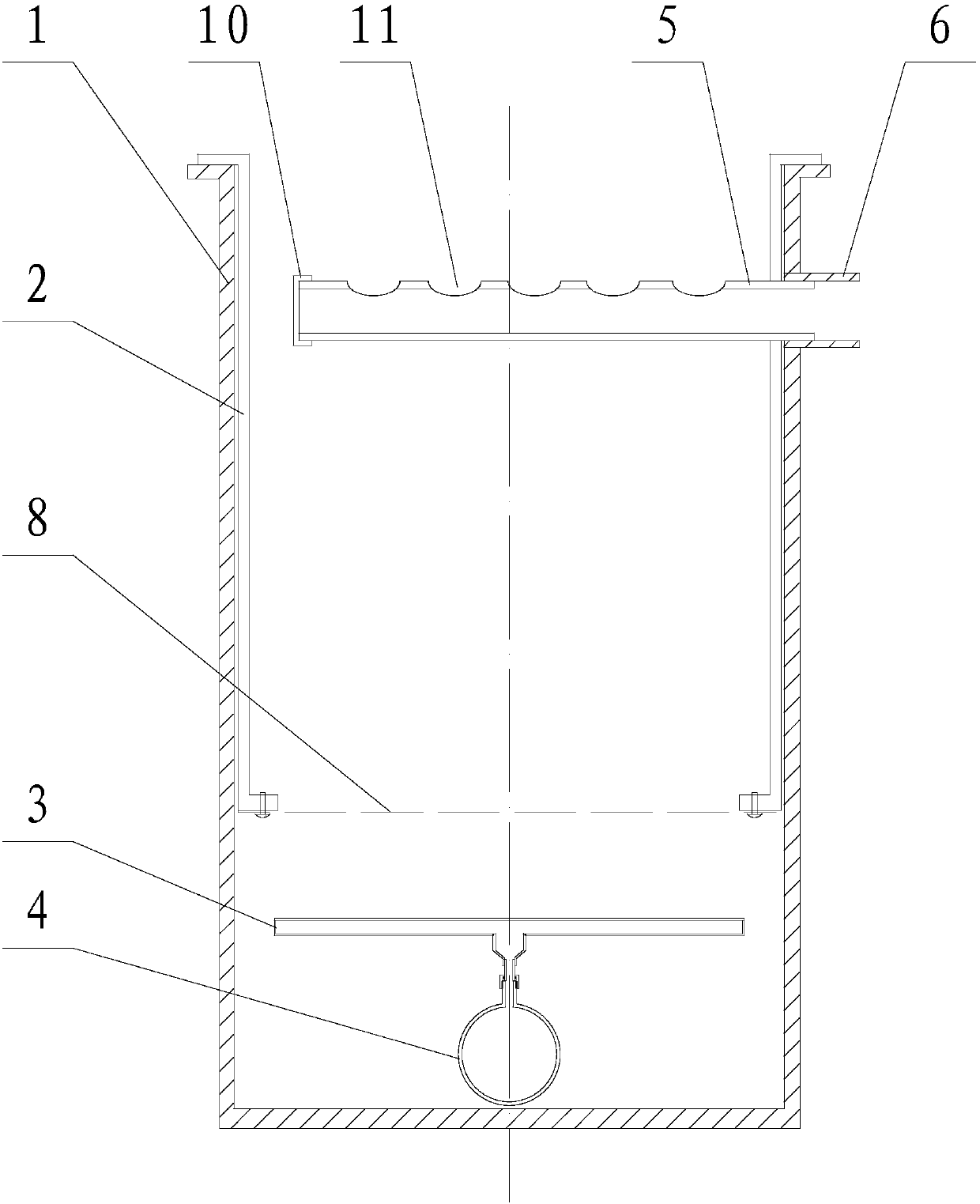

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Such as Figure 1~3 As shown, the present invention includes a water tank 1, a culture tank 2, a disc rotary water distributor 3, a water inlet pipe 4, an aqueduct 5, a drain pipe 6 and a screen 8, wherein at least one culture tank 2 is installed in the water tank 1, and the water tank 1 is a cuboid, and the culture tank 2 is a cylinder with both ends opening, and the bottom of the culture tank 2 is fixed with a water-permeable screen 8; When the culture tank 2 is multiple, it is arranged side by side along the length direction of the water tank 1, and the bottom between the adjacent culture tanks 2 is provided with a water barrier 7 installed in the water tank 1, and the water barrier 7 is an impermeable solid flat plate, The lower end of water baffle 7 is close to water inlet pipe 4, and the upper end is higher than the screen cloth 8 that culture t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com