Method for processing alliinase in radiofrequency passivated garlic

A technology of alliinase and processing methods, applied in food heat treatment, food science, etc., can solve the problems of high environmental protection pressure, large amount of waste water, slow heat transfer speed and garlic tissue, and achieve the effect of reducing water consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

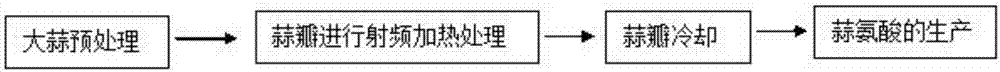

Image

Examples

Embodiment 1

[0021] The radio frequency device with the application publication number CN104782758A is used to process garlic; wherein, the radio frequency device includes a conveying device and a radio frequency device with an upper plate and a lower plate, the upper plate is located above the conveying device, and the material conveyed by the conveying device is on the upper pole The plate moves between the lower plate, and both the upper plate and the lower plate are passed with high-frequency current. Thus, after the high-frequency current passes through the upper pole plate and the lower pole plate, there is radio frequency between the two, and the conveying device drives the material to move between the upper pole plate and the lower pole plate.

[0022] The specific processing steps are as follows:

[0023] (1) Pretreatment: Select fresh garlic, wash it with water and peel off the cloves. The thickness of the garlic cloves is 8-10mm (thickness is smaller than the distance between th...

Embodiment 2

[0028] Application radio frequency heating treatment device (publication number is CN104782758A) garlic clove is processed, concrete steps are as follows:

[0029] (1) Pretreatment: Select fresh garlic, wash it with water and peel off the petals.

[0030] (2) Radio frequency treatment: Place the cut garlic cloves on the conveyer belt at the center of the pole plate under the radio frequency treatment chamber. The operating frequency of the radio frequency treatment device is 27.12MHz, the power is set to 3.5kW, different pole plate spacings are set, and the sample thickness is 9mm, set different processing times, control the auxiliary temperature in the RF treatment chamber to 55°C, the auxiliary temperature is provided by hot air ≥ 55°C, and an external hot air generator can be selected to collect ambient air and heat it through a 5.6kW electric heater The device is heated to the set temperature and flows into the radio frequency processing chamber to heat the entire radio fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com