Double gear forging process and die based on sheet metal volume forming

A double gear, forming and forging technology, applied in the direction of manufacturing tools, wheels, metal processing equipment, etc., can solve the problems of small forming load, long processing cycle, high mold cost, avoid heating process, improve production efficiency, improve forming The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

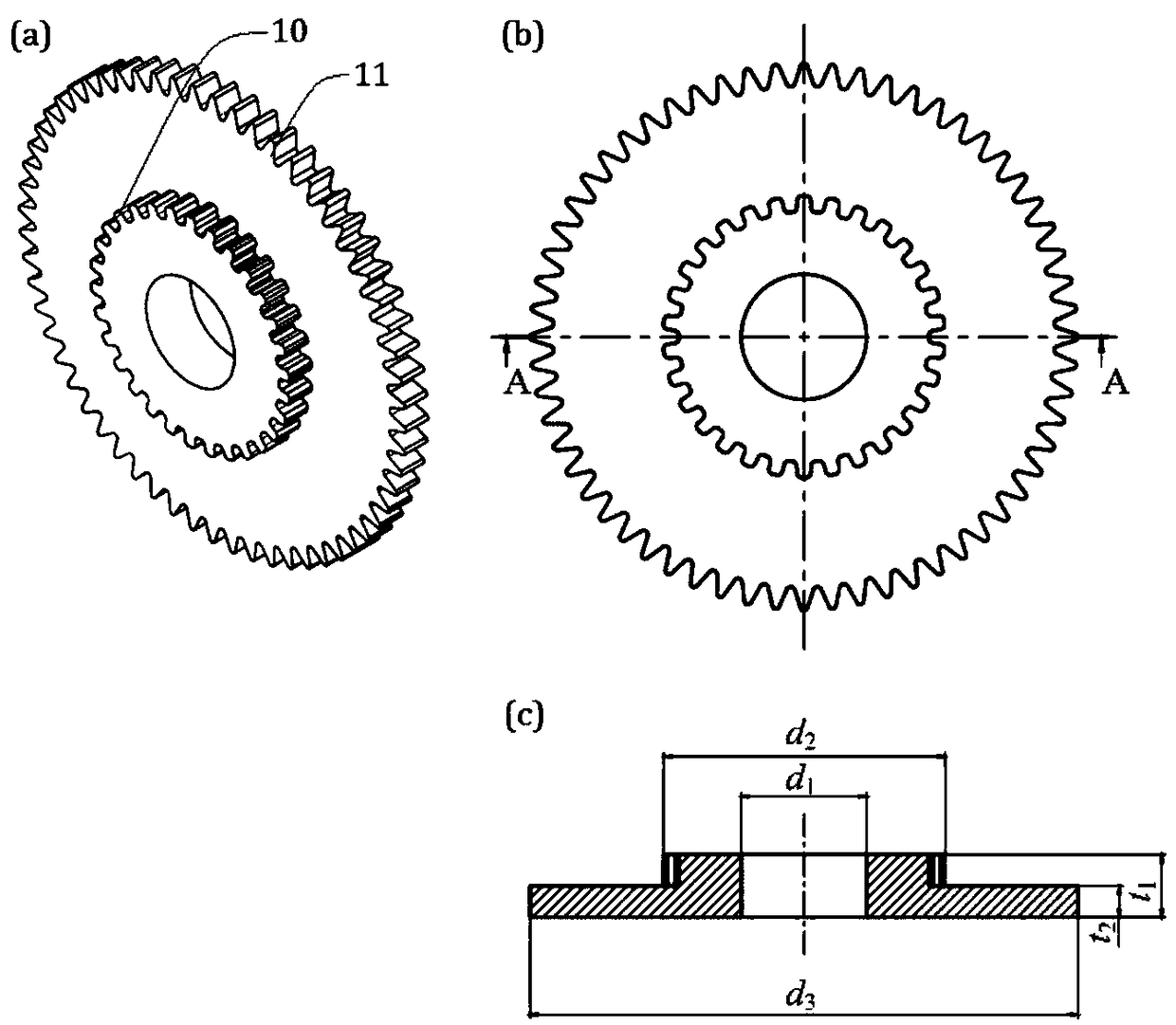

[0034] Such as figure 1 As shown, the present embodiment relates to a dual gear, and the overall height of the dual gear is t 1 , flange outer gear 11 high t 2 , Flange internal teeth 10 high t 1 -t 2 , the core has a diameter d 1 The shaft hole, the flange inner teeth 10 are evenly distributed on the diameter d 2 On the outer circumference of the flange, the flange outer teeth 11 are evenly distributed on the diameter d concentric with the shaft hole and the central flange 3 on the outer circumference of .

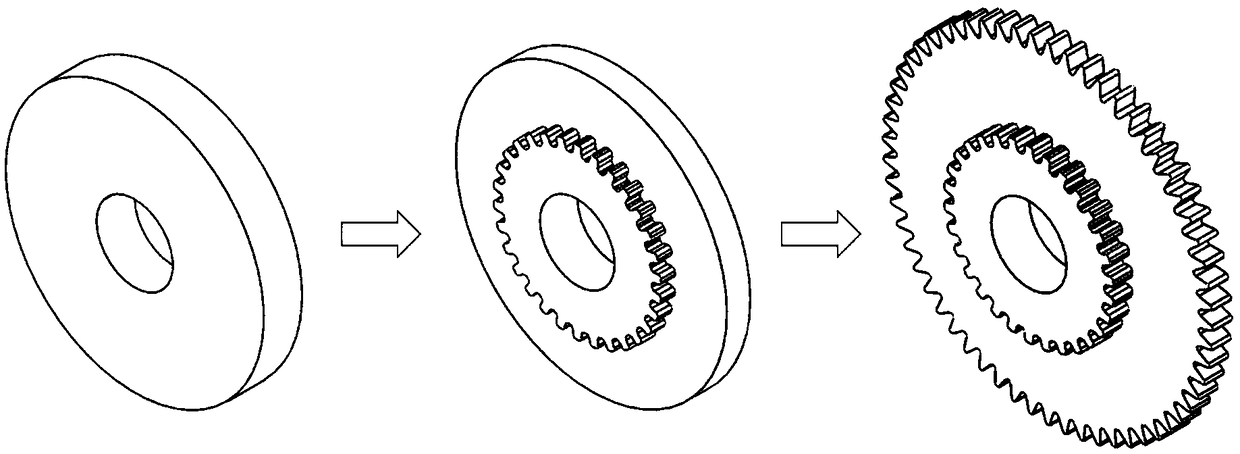

[0035] Such as figure 2 As shown, this embodiment relates to a dual-gear forging process based on sheet metal volume forming. First, according to the designed finished product, an annular slab is obtained by laser cutting or punching. The original thickness of the annular slab is t 1 , the outer diameter is d 0 , the inner diameter is d 1 Then, the flange inner teeth 10 are sheared and formed, and the flange area on the outer side of the inner teeth is upset and...

Embodiment 2

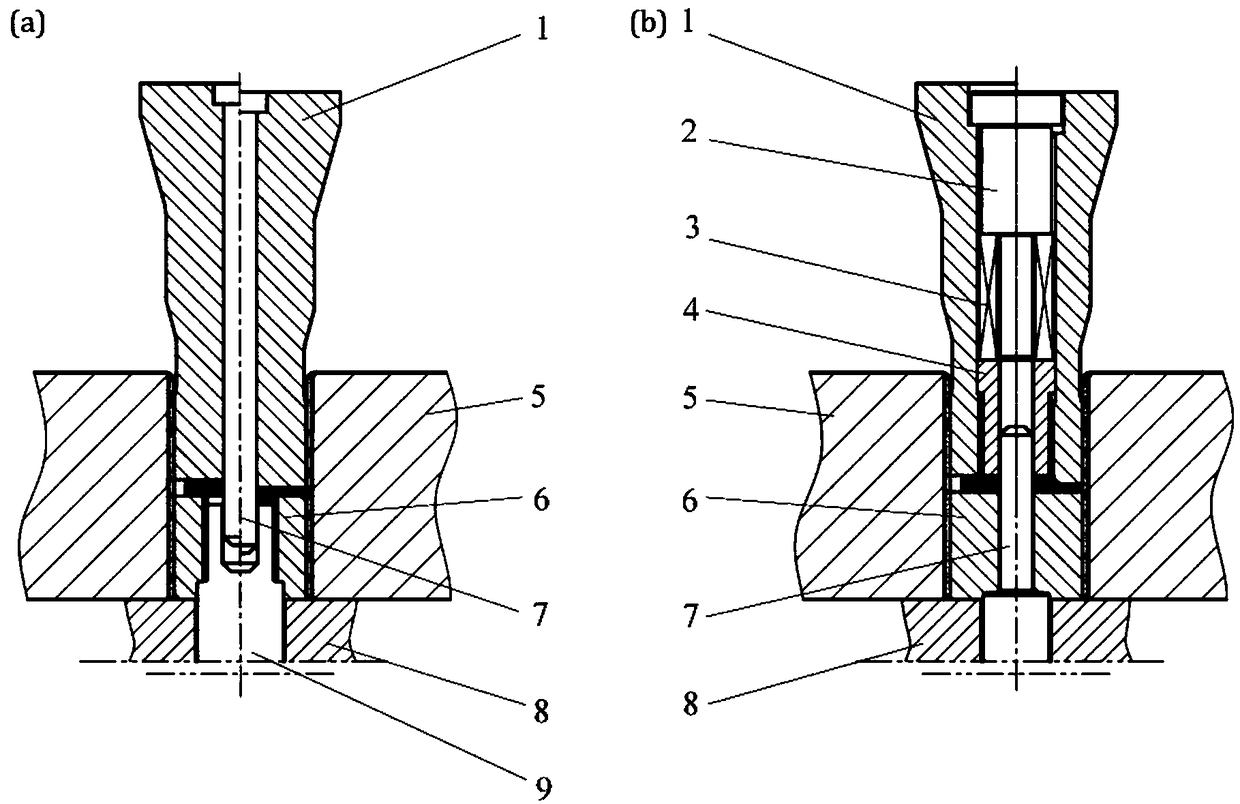

[0046] Such as image 3 (b) and Figure 5As shown in (b), this embodiment relates to a die for forging double gears based on the sheet metal volume forming process using reverse forming, including a coaxial punch 1, a disc spring core 2, a disc spring group 3, Back pressure counter-top block 4, die 5 and die insert 6, wherein: die 5 is provided with a forming cavity, the upper part of the forming cavity is provided with a punch 1, and the lower part is provided with a ring-shaped die insert 6, the punch 1 is provided with a shaft hole, and the disc spring core 2, the disc spring group 3 and the back pressure reverse jacking block 4 are arranged in the shaft hole in sequence from top to bottom. It is loosely fitted and can move longitudinally relative to the forming cavity and the back pressure counter jacking block 4, and the annular slab is arranged between the punch 5, the back pressure counter jacking block 4 and the die insert 6;

[0047] The inner side of the die 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com