Casting technology for CAP1400 nuclear main pump shell

A casting process, nuclear main pump technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., to achieve the effect of satisfying the quality of castings, improving research efficiency, and reducing research costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

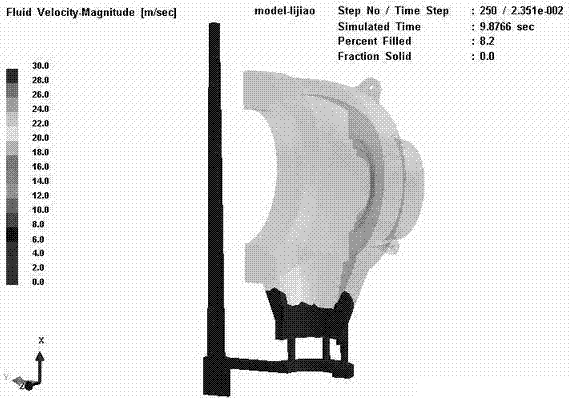

[0043] The establishment process of the technical solution is described in conjunction with the accompanying drawings, which are specifically divided into the following steps:

[0044] (1) Analysis of casting characteristics of nuclear main pump

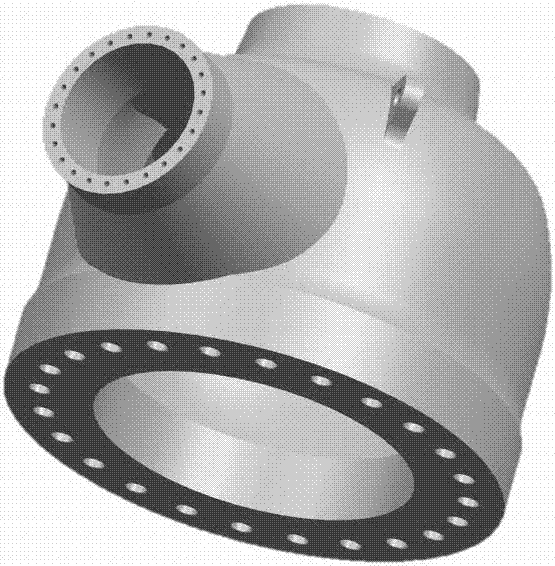

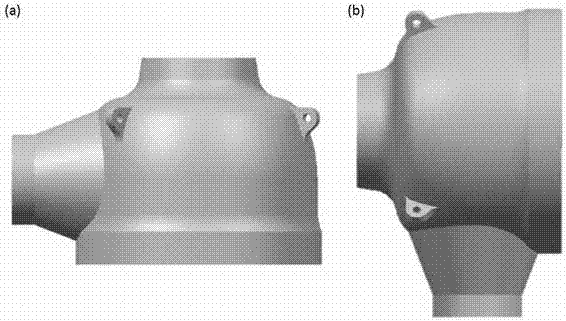

[0045] Before carrying out casting process design, fully study the performance requirements, material and structural characteristics of castings, and carry out process design according to the characteristics of castings. According to the casting drawings, the 3D modeling software UG9.0 is used to construct the 3D model of the casting, such as figure 1 shown.

[0046] CAP1400 nuclear main pump casing, the main body is a gyratory body with a large inner cavity, one side protrudes, the wall thickness of the casting is uneven, the upper and lower sides meet the side wall to form a heat joint, and the upper part is symmetrically distributed with four lifting lugs. The outer frame size of the casting is 2817mm╳2235mm╳1870mm. Using the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com