Solid wire

A technology of solid welding wire and welding wire, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc. It can solve the problem that the straightness and correction of large-diameter welding wires cannot be said to be sufficient, and achieves easy straightening and delivery. Improvement, the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

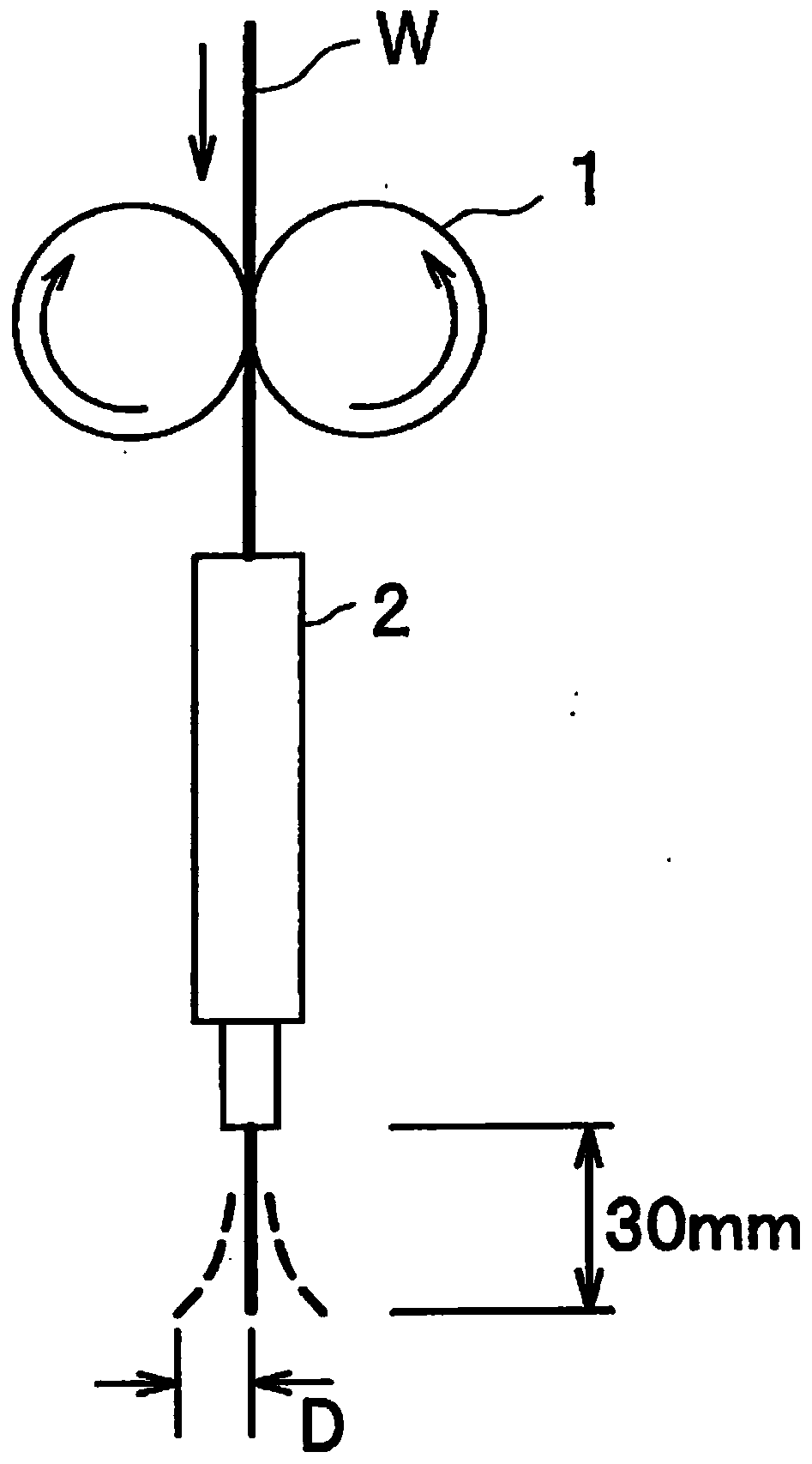

Method used

Image

Examples

Embodiment Construction

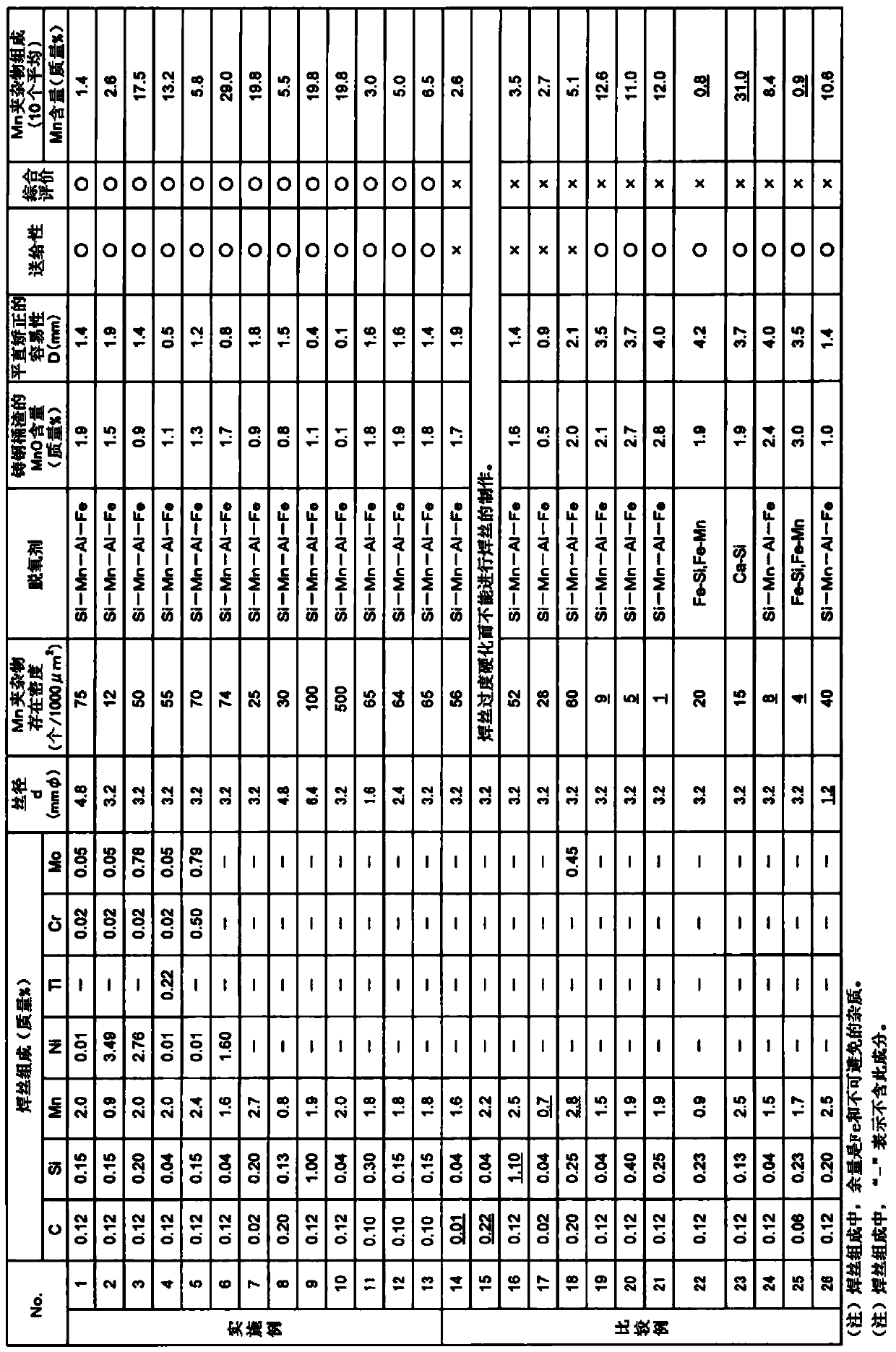

[0025] Embodiments of implementing the solid welding wire (hereinafter referred to as welding wire) of the present invention will be described in detail.

[0026] Even if the welding wire has the same composition, and even if the welding wire is produced by the same manufacturing method, when these welding wires are supplied to welding, the easiness of straightening the welding wire varies and the arc stability varies due to the difference in the manufacturing lot of the welding wire. Therefore, when the cross-sections of these welding wires were examined in detail, it was found that inclusions exist in the cross-sections of the original wires of the welding wires, and the inclusions significantly affect the easiness of straightening of the welding wires.

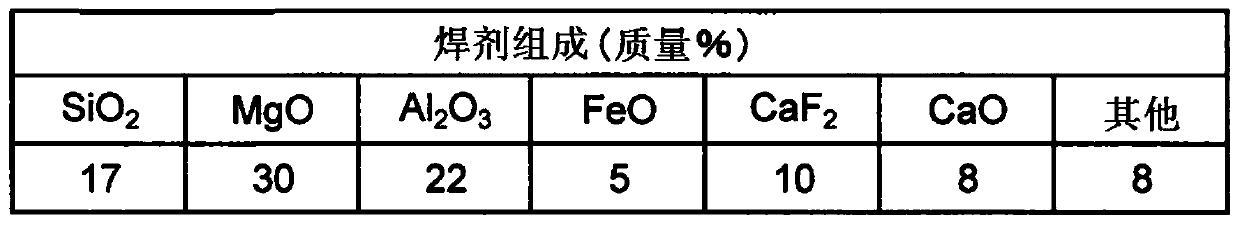

[0027] The welding wire of the present invention, based on the total mass of the welding wire, contains C: not less than 0.02% by mass and not more than 0.20% by mass, Si: not more than 1.0% by mass, Mn: not less than 0.8% b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com