Jet-printing method and system for multi-color patterns on regular geometrical workpieces

A color pattern and geometric shape technology, applied in the direction of copying/marking methods, printing, printing devices, etc., can solve the problems of reducing the printing yield of regular geometric workpieces, prone to deviations in the position of smearing, and difficult to determine the measurement of adhesives, etc. , to achieve the effect of reducing scrap rate, avoiding waste and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

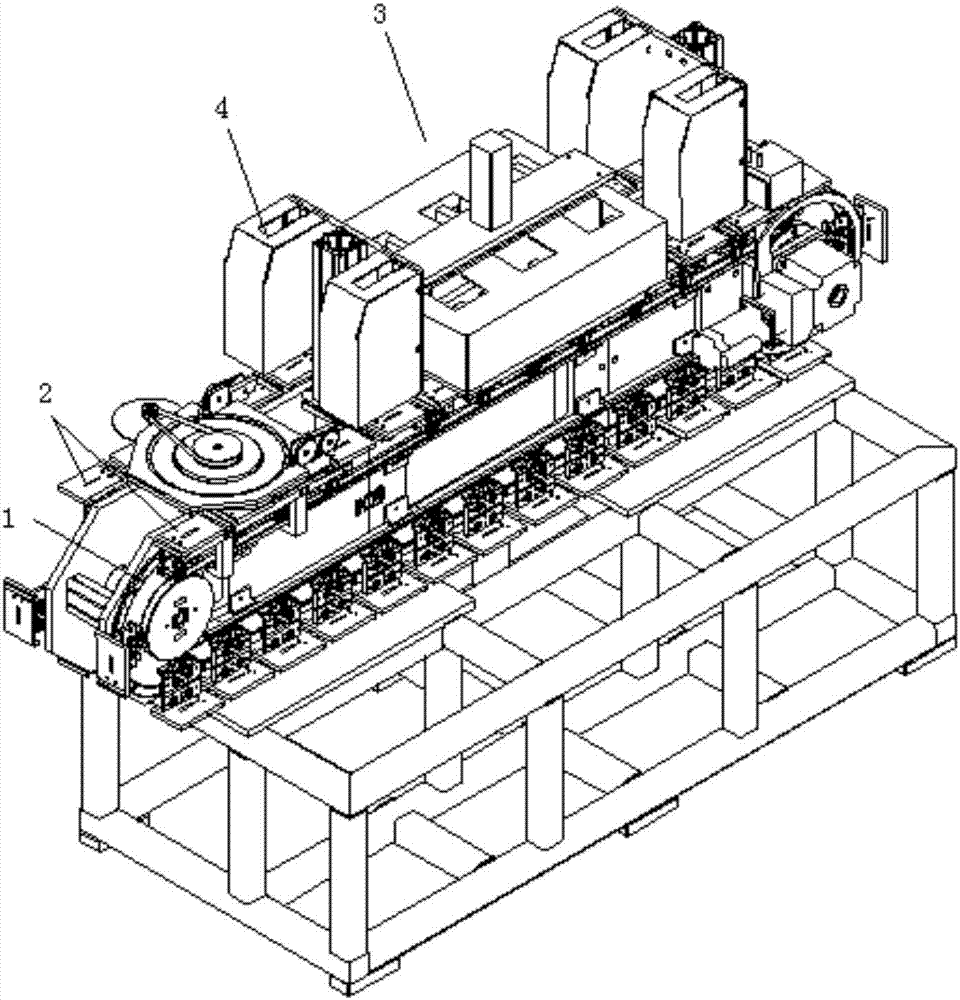

[0031] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

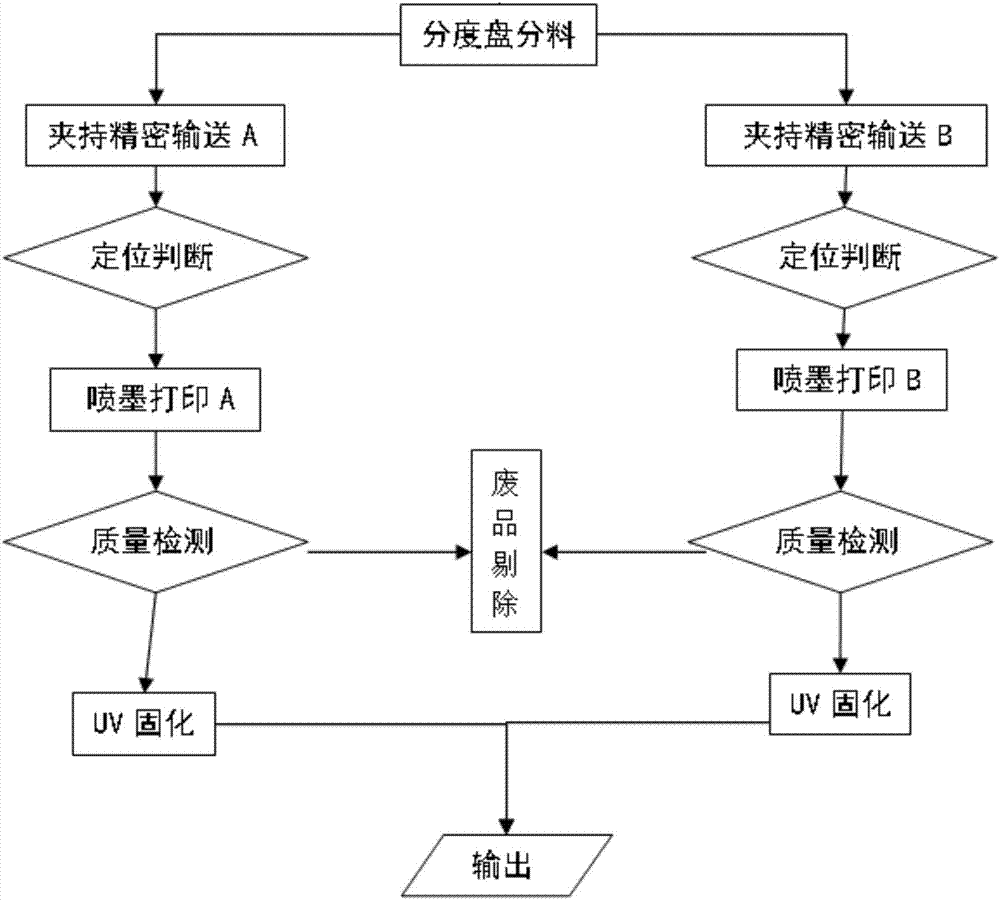

[0032] Such as figure 1 , the inkjet printing method of the color pattern on the regular geometry work piece that the present embodiment provides, such as figure 1 , including the following steps:

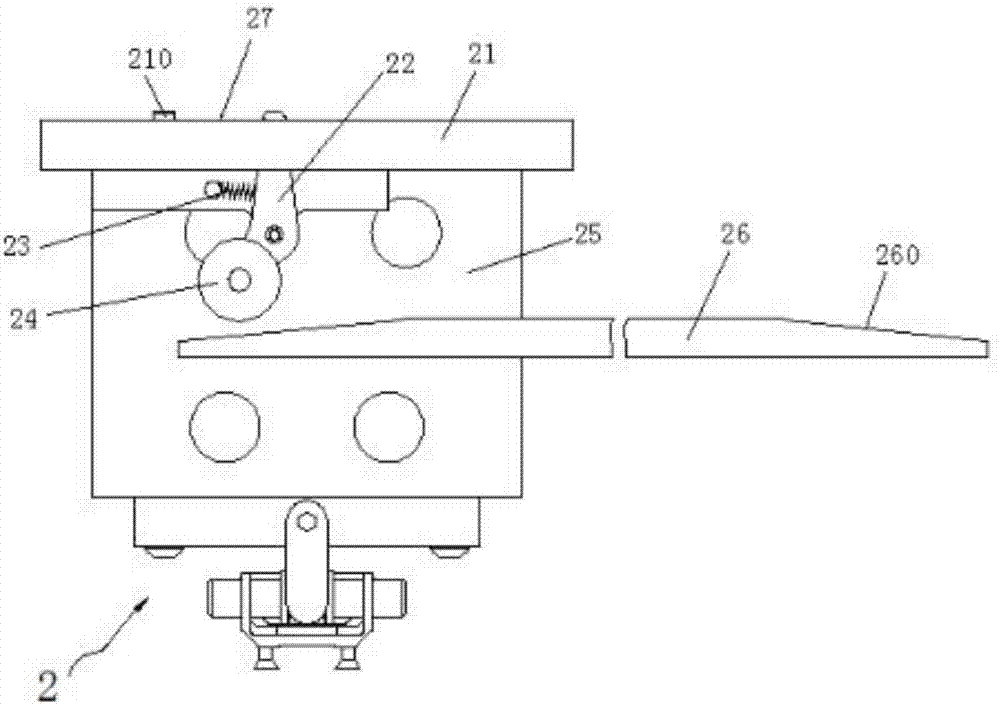

[0033] First, fix the workpiece with regular geometry on the conveyor belt and drive it horizontally by the conveyor belt;

[0034] The regular geometric workpieces on the conveyor belt pass through the CCD camera one by one for image acquisition, and the printing parameters corresponding to each regular geometric workpiece are obtained according to the pattern to be printed; the conveyor belt passes through the inkjet printing unit containing several nozzles, inkjet printing The unit prints the regular geometric workpiece according to the printing parameters, and finally forms exactly the same pattern;

[0035] Then take photos of the printed regular g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com