Snakelike mechanism guide rail

A guide rail and snaking technology, which is applied to conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of undurable conveyor belts, small turning angle range, high cost of use, etc., to meet the requirements of fast picking work, reasonable structural design, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

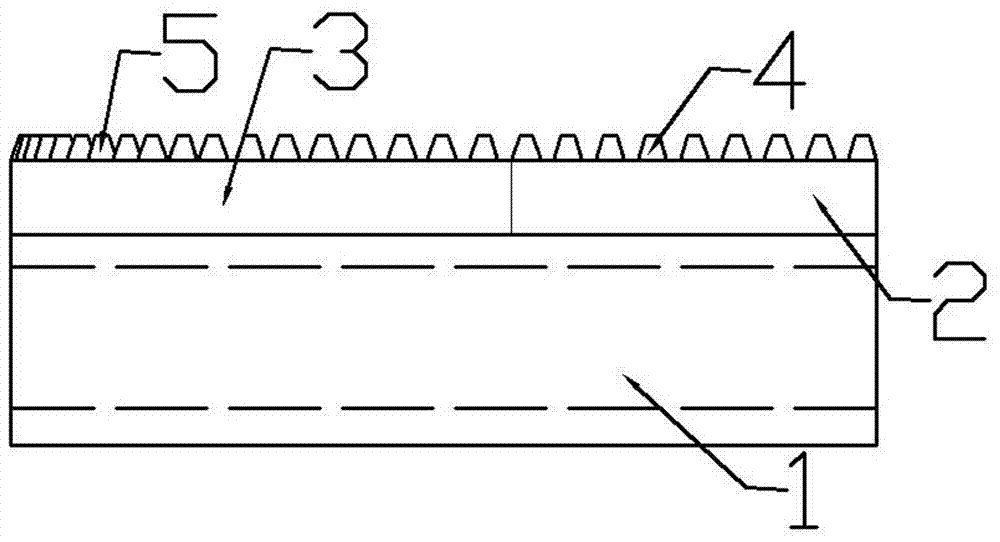

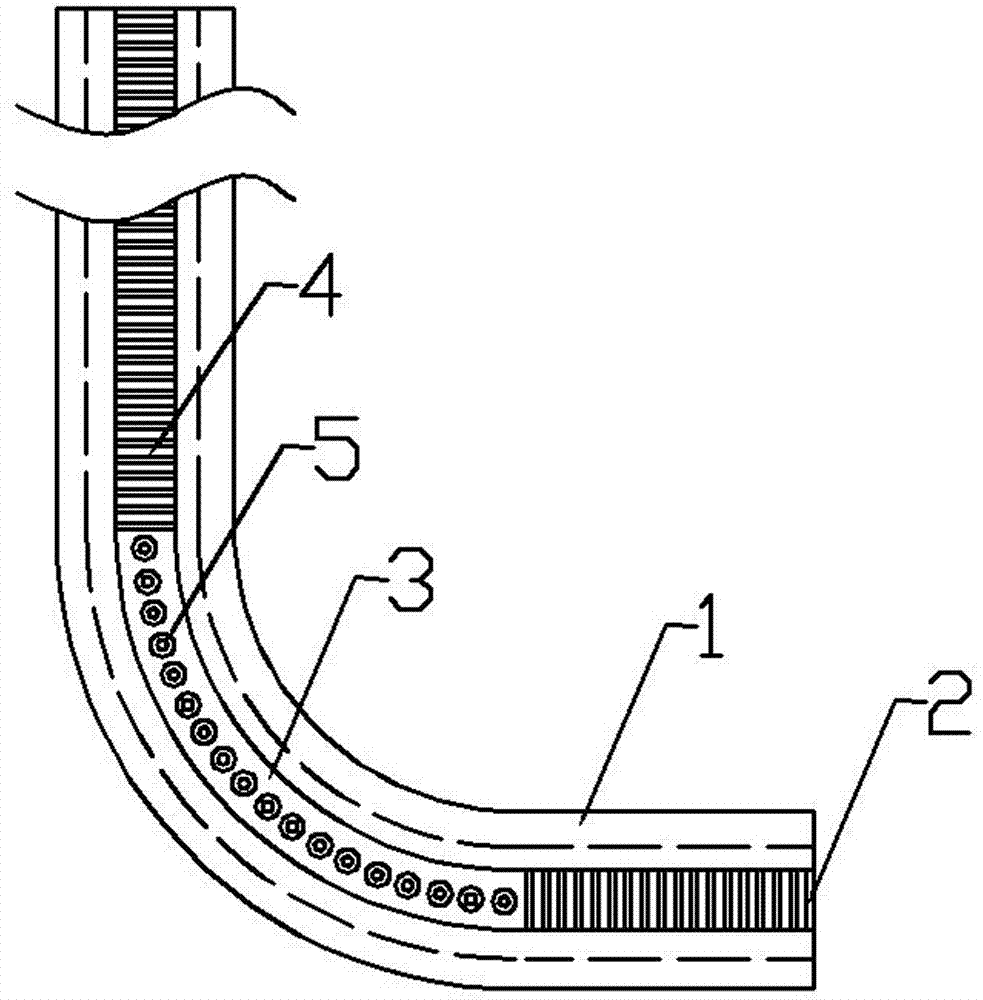

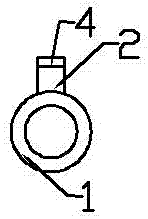

[0017] The snake guide rail provided by the present invention includes a track and teeth on the track. The track is erected on a cylindrical pipe 1. The pipe 1 is cylindrical, which can ensure that the mechanical equipment on it performs linear contact motion with it, rather than surface contact. Reduce friction and save energy; the track sections are set to straight track 2 and curved track 3. The teeth match the standard transmission gears of the working mother machine, including standard teeth 4 and special-shaped teeth 5. The standard teeth 4 are located on the straight track 2, which is conventional The standard rack section is convenient for the straight running of the standard working machine; the special-shaped tooth 5 is located on the center line of the curved track 3, and the special-shaped tooth 5 is in the shape of a truncated cone. The tooth pitch is equal to the tooth pitch of the standard tooth 4, and the tooth height of the profiled tooth 5 is equal to the tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com