Improved LiNH2-LiH composite hydrogen storage material and method for improving hydrogen storage properties

A technology for hydrogen storage materials and mixtures, which is applied in chemical instruments and methods, hydrogen and hydrogen production, etc., can solve problems such as insufficiency, and achieve improved hydrogen storage performance, low hydrogen desorption starting temperature, and cyclic hydrogen absorption and desorption. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Ball milling LiNH 2 Mix the sample with LiH (1:1): In an argon glove box, weigh the LiNH 2 0.3 g of a sample mixed with LiH crystal at a mass ratio of 1:1 was put into a ball mill jar containing 20 stainless steel balls. Take out the ball mill jar, fill it with 0.6MPa hydrogen, and install the ball mill jar symmetrically in a planetary ball mill, and perform ball milling treatment at a speed of 450 rpm for 2 hours.

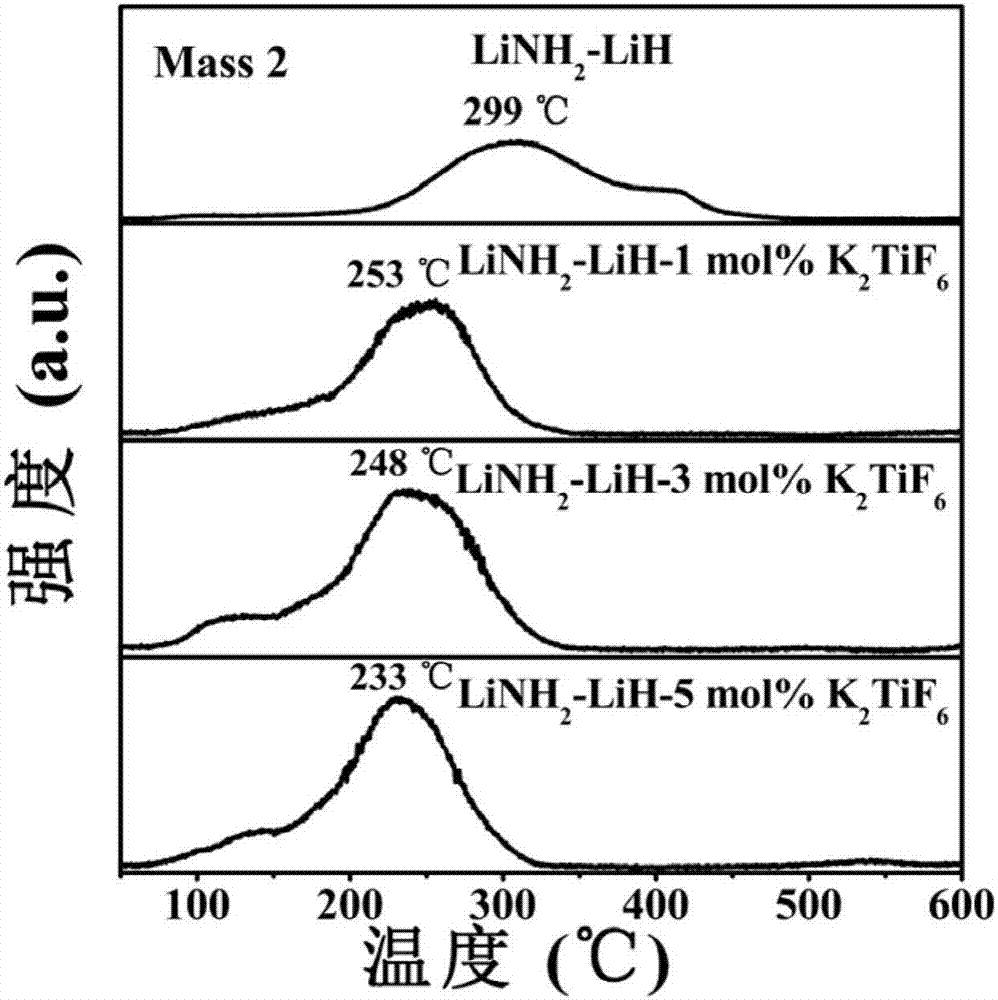

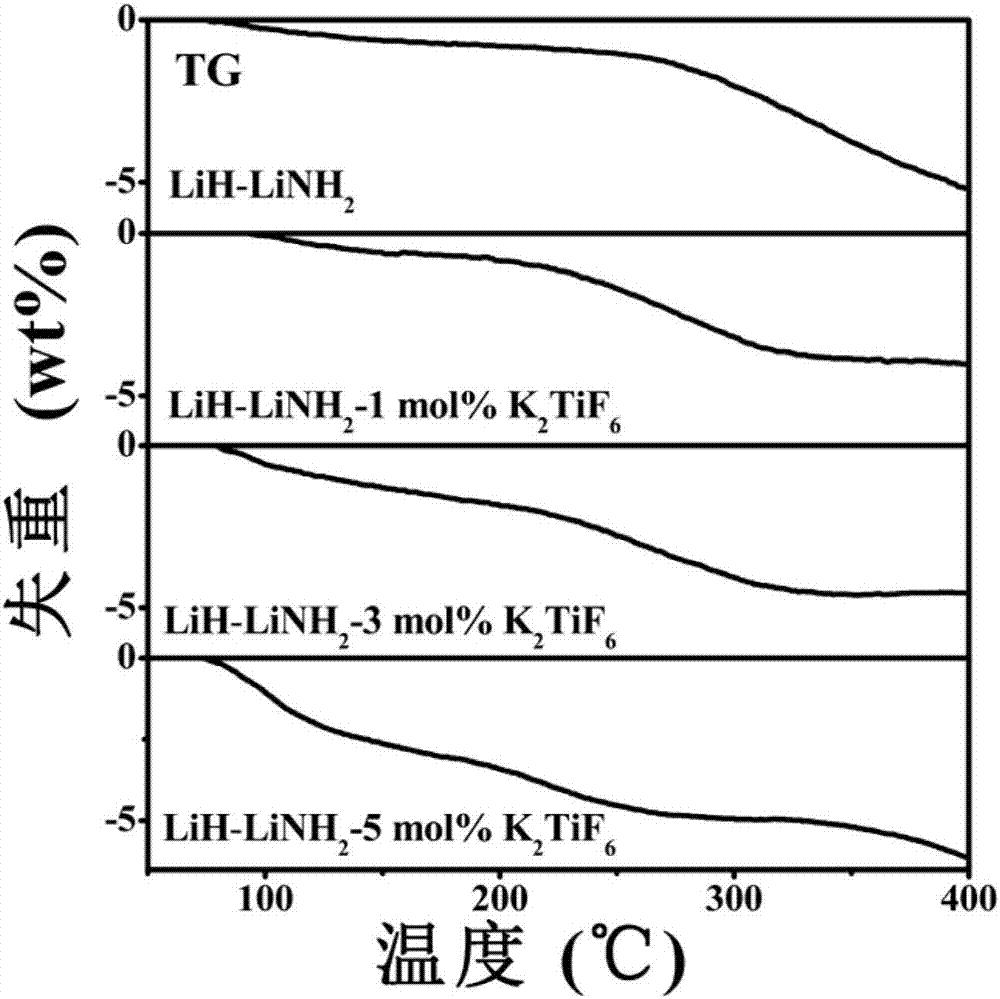

[0024] 2. LiNH after ball milling 2 - LiH mixed samples for hydrogen thermal desorption test: In an argon glove box, recovery of LiNH after ball milling 2 Mix the sample with LiH, take 13mg LiNH after ball milling 2 - LiH mixed sample, hydrogen desorption test by thermal mass spectrometer, the gas signal is detected as H 2 , the condition is an argon atmosphere (the flow rate is 20ml min -1 ), 50~600℃, the heating rate is 10k / min. Undoped LiNH can be obtained 2 -The onset and peak temperature of hydrogen desorption of LiH system, and the weight lo...

Embodiment 2

[0027] 1. Mix LiNH with a mass ratio of 1:1 2 mixed with LiH first, and then doped with 1mol% K 2 TiF 6 , 3mol%K 2 TiF 6 and 3mol%K 2 TiF 6 get K 2 TiF 6 Doped LiNH 2 and LiH mixed crystals.

[0028] Doping K 2 TiF 6 LiNH 2 Mixed crystals with LiH: In an argon glove box, weigh 0.3g doped K 2 TiF 6 LiNH 2 Mix crystals with LiH into a ball mill jar containing 20 stainless steel balls. Then take out the ball mill jar from the glove box, fill it with 0.6MPa hydrogen, and install the ball mill jar symmetrically in the planetary ball mill, and ball mill it for 2 hours at a speed of 450 rpm.

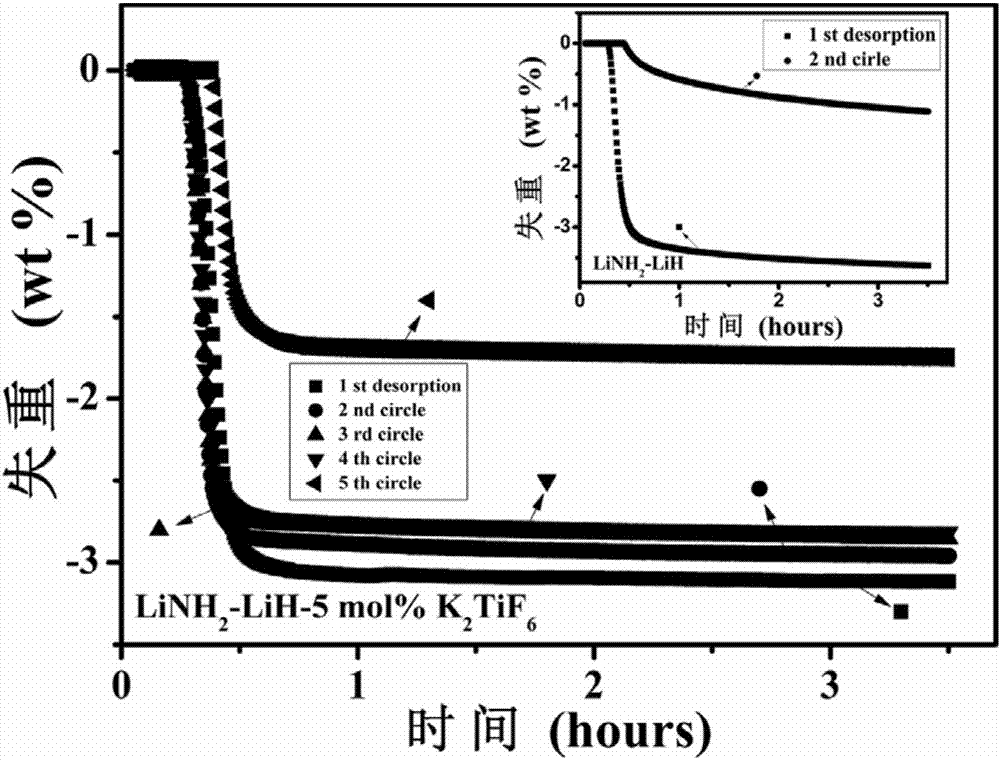

[0029] 2. Doped with different content of K after ball milling 2 TiF 6 LiNH 2 -LiH mixed samples were tested for hydrogen thermal desorption: In an argon glove box, different amounts of K were recovered after ball milling 2 TiF 6 LiNH 2 - LiH mixed samples, respectively take 13mg ball milled and doped with 1mol%, 3mol% and 5mol% K 2 TiF 6 LiNH 2 - LiH mixed samples were ...

Embodiment 3

[0032] 1. Mix LiNH with a mass ratio of 1:1 2 Mixed with LiH first, then doped with 5mol% TiF4 to obtain LiNH doped with TiF4 2 and LiH mixed crystals.

[0033] LiNH doped with 5mol% TiF4 2 Mixed crystals with LiH: In an argon glove box, weigh 0.3g of LiNH doped with 5mol% TiF4 2 Mix crystals with LiH into a ball mill jar containing 20 stainless steel balls. Then take out the ball mill jar from the glove box, fill it with 0.6MPa hydrogen, and install the ball mill jar symmetrically in the planetary ball mill, and ball mill it for 2 hours at a speed of 450 rpm.

[0034] 2. Hydrogen desorption test for samples after ball milling: In an argon glove box, recover LiNH doped with 5mol% TiF4 after ball milling 2 Mix the sample with LiH, take 13mg of LiNH doped with 5mol% TiF4 after ball milling 2 The mixed sample with LiH was tested for hydrogen desorption by thermal mass spectrometer, and the gas signal was detected as H 2 , the condition is an argon atmosphere (the flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com