Li3N hydrogen storage material doped with multiwalled carbon nanotubes to improve hydrogen storage performance and preparation method thereof

A technology of multi-walled carbon nanotubes and hydrogen storage materials, which is applied in the field of solid-state chemical hydrogen storage of light elements, can solve the problems that the performance of hydrogen storage materials cannot meet the specified and expected effects, and achieve improved hydrogen desorption performance, promotion of dispersion, Effect of improving hydrogen absorption and desorption kinetics and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

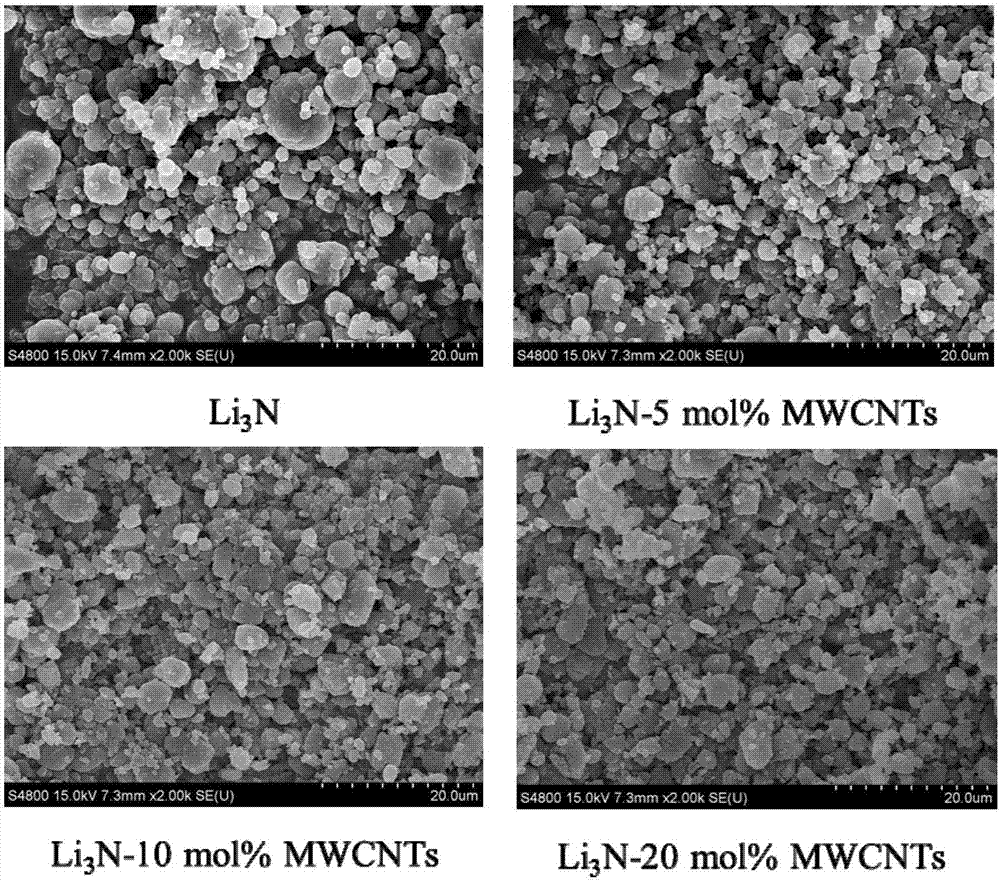

[0024] 1. Ball milling force 3 N pure sample: in an argon glove box, weigh pure Li 3 N sample 0.3g, put into a ball mill jar containing 30 stainless steel balls. The mass ratio of ball milling balls to powder is about 90:1. Then take out the ball mill jar from the glove box, fill it with 0.6MPa argon gas, and install the ball mill jar symmetrically in the planetary ball mill, and ball mill it for 2 hours at a speed of 450 rpm.

[0025] 2. Li after ball milling 3N pure sample morphology test: take a small part of Li in an argon glove box 3 N pure samples were quickly smeared on the SEM sample stage, sprayed for 15s, and placed in the electron microscope scanner, with a set size of 20μm and a magnification of 15.0kv. Then observe and shoot.

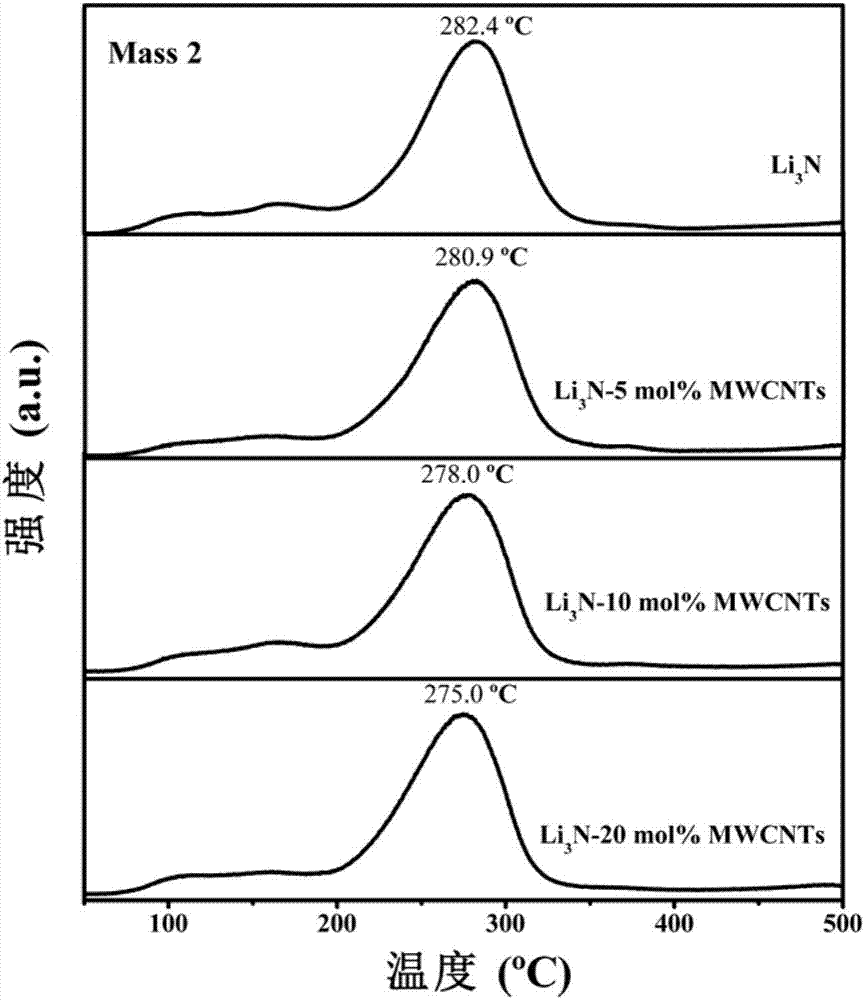

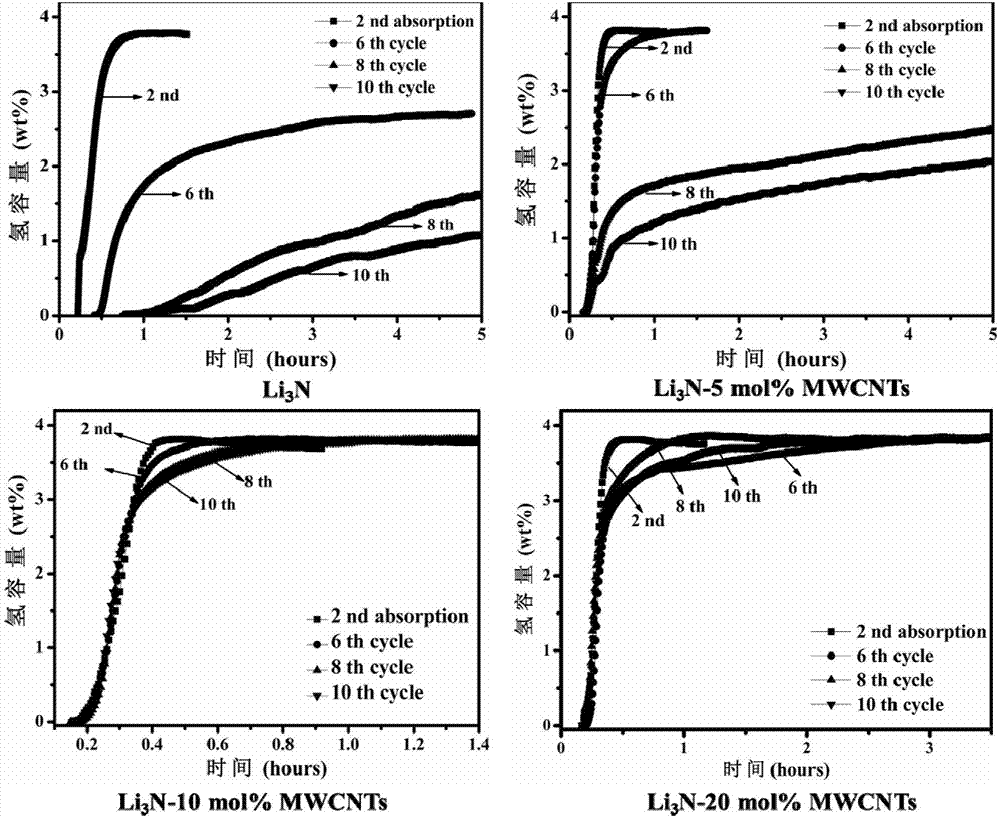

[0026] 3. The sample after ball milling was subjected to hydrogen desorption test: in an argon glove box, take 13 mg of Li after ball milling 3 N pure samples were tested for hydrogen desorption by thermal mass spectrometry, and the g...

Embodiment 2

[0029] 1. Ball milling of Li doped with 5mol% MWCNTs 3 N mixed samples to obtain Li doped MWCNTs 3 N mixed crystals:

[0030] Li doped with 5 mol% MWCNTs 3 N mixed samples: in an argon glove box, weigh pure Li 3 A total of 0.3 g of N sample and 5mol% MWCNTs were put into a ball mill jar containing 30 stainless steel balls. The mass ratio of ball milling balls to powder is about 90:1. Then take out the ball mill jar from the glove box, fill it with 0.6MPa argon gas, and install the ball mill jar symmetrically in the planetary ball mill, and ball mill it for 2 hours at a speed of 450 rpm.

[0031] 2. Li doped with 5mol% MWCNTs after ball milling 3 Morphology test of N mixed samples: a small portion of Li doped with 5 mol% MWCNTs was taken in an argon glove box 3 N mixed samples were quickly smeared on the SEM sample stage, sprayed for 15s, and placed in the electron microscope scanner, with a set size of 20μm and a magnification of 15.0kv. Then observe and shoot.

[0032...

Embodiment 3

[0035] 1. Ball milling of Li doped with 10 mol% MWCNTs 3 N mixed samples to obtain Li doped MWCNTs 3 N mixed crystals:

[0036] Li doped with 10 mol% MWCNTs 3 N mixed samples: in an argon glove box, weigh pure Li 3 A total of 0.3 g of N sample and 10mol% MWCNTs were loaded into a ball mill jar containing 30 stainless steel balls. The mass ratio of ball milling balls to powder is about 90:1. Then take out the ball mill jar from the glove box, fill it with 0.6MPa argon gas, and install the ball mill jar symmetrically in the planetary ball mill, and ball mill it for 2 hours at a speed of 450 rpm.

[0037] 2. Li doped with 10mol% MWCNTs after ball milling 3 Morphology test of N mixed samples: taking a small part of Li doped with 10 mol% MWCNTs in an argon glove box 3 N mixed samples were quickly smeared on the SEM sample stage, sprayed for 15s, and placed in the electron microscope scanner, with a set size of 20μm and a magnification of 15.0kv. Then observe and shoot.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com