A high breakdown field strength and energy storage density silicon dioxide doped copper cadmium titanate giant dielectric ceramic material and preparation method

A technology of ceramic materials and silicon dioxide, applied in circuits, capacitors, electrical components, etc., can solve the problem of low energy storage density, achieve low reaction temperature, strong practicability, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

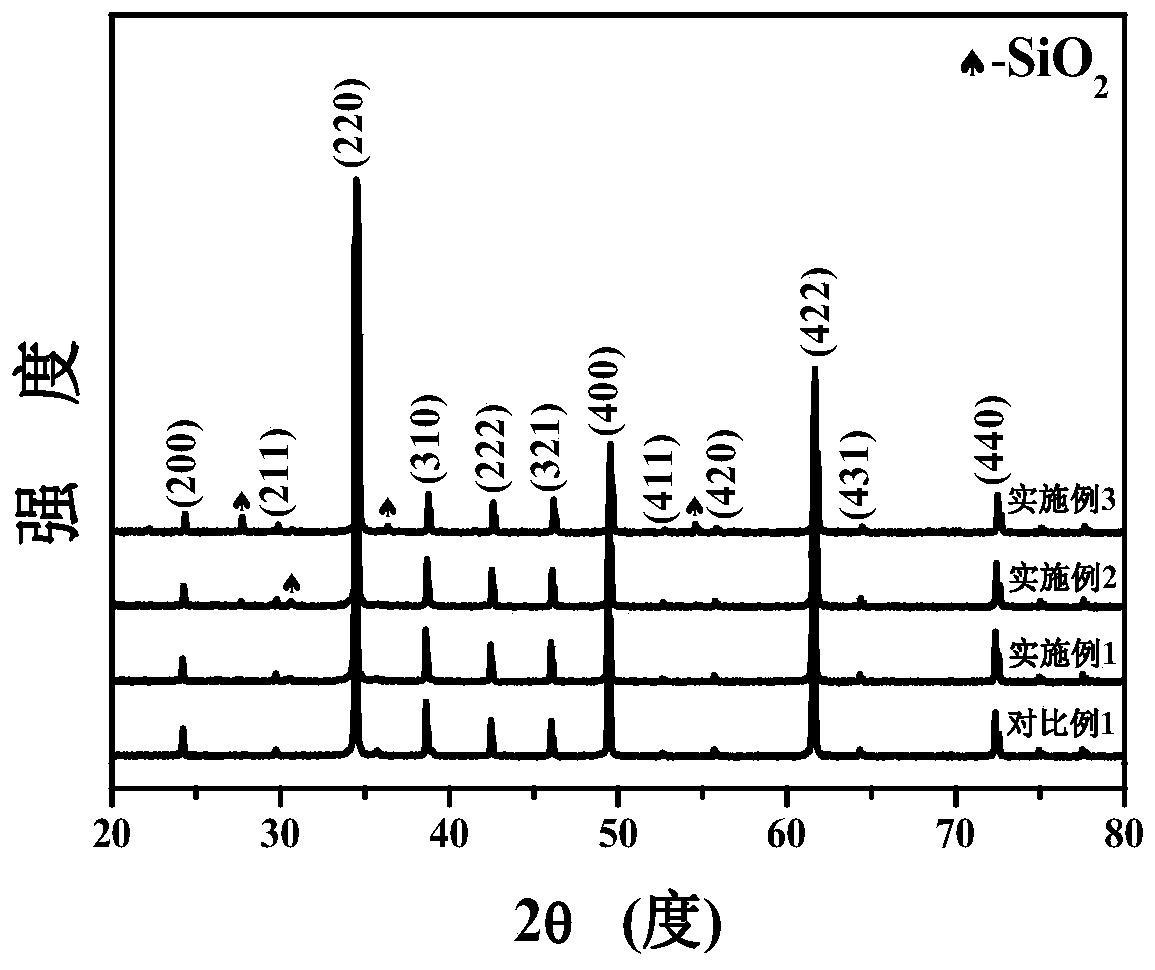

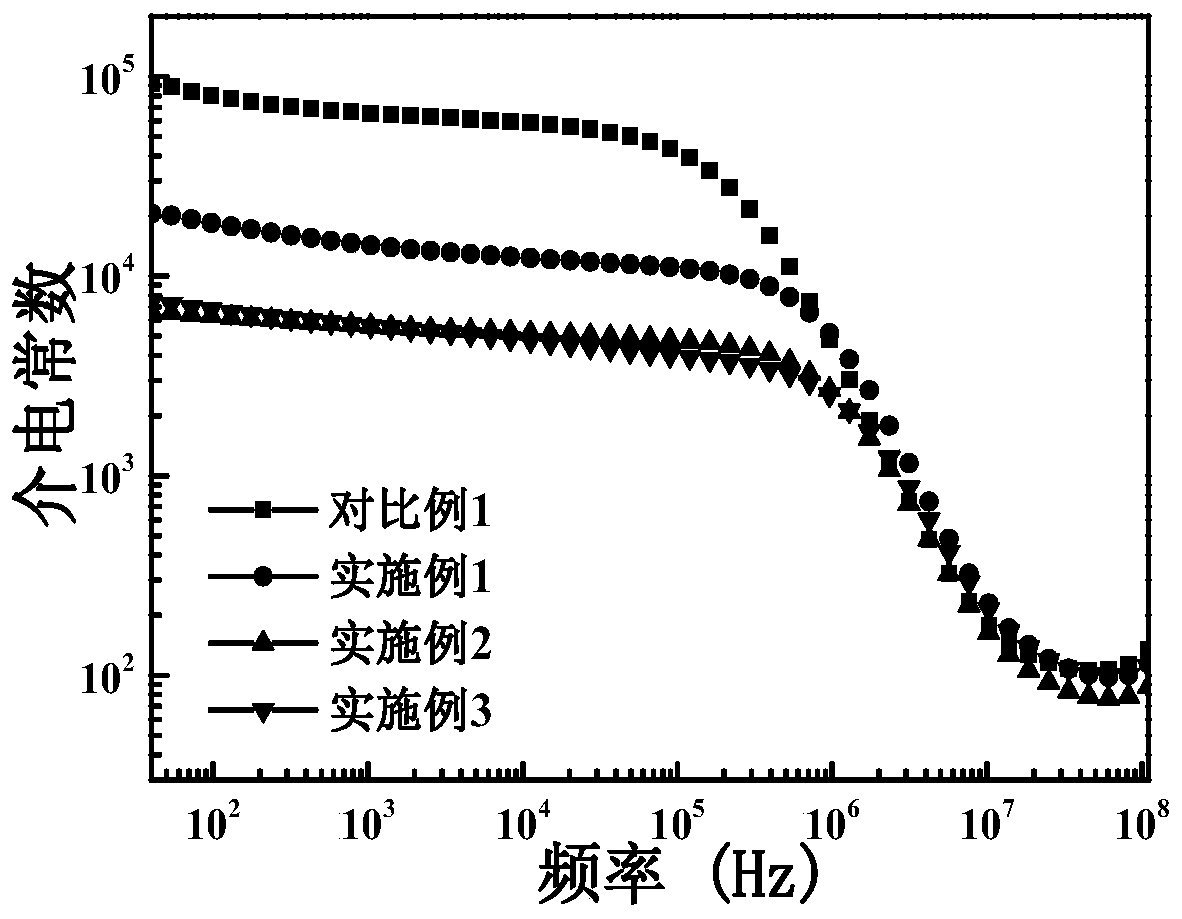

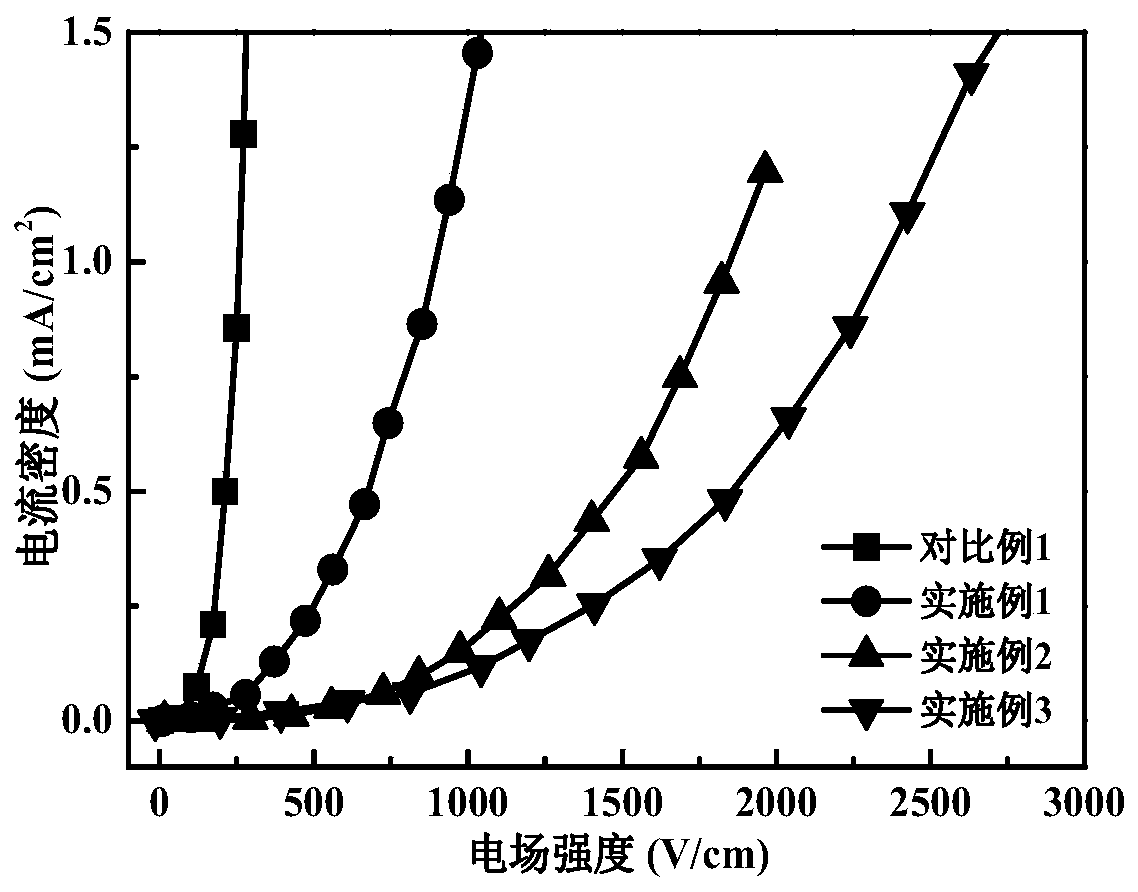

Embodiment 1

[0021] 1. According to CdCu 3 Ti 4 o 12 The stoichiometric ratio of 3.1159g Cd(NO 3 ) 2 4H 2 O, 7.3212g Cu(NO 3 ) 2 ·3H 2 O was added to the mixed solvent of 10mL absolute ethanol and deionized water to prepare solution A, and 13.8mL Ti(C 4 h 9 O) 4 Add it to 52.2mL of absolute ethanol to prepare solution B; mix solution A and solution B, and add 4mL of glacial acetic acid, the concentration of butyl titanate in the resulting mixed solution is 0.5mol / L, and the volume fraction of glacial acetic acid is 5.0 %, the volume fraction of deionized water is 10%, heated at 45°C and stirred evenly to obtain a sol, and continued to stir until the sol turned into a gel. After the gel was aged for 12 hours, it was dried at 100°C for 48 hours. A brownish blue loose xerogel is obtained; after the xerogel is ground, it is calcined at 650°C for 10 hours to obtain CdCu 3 Ti 4 o 12 Ceramic powder.

[0022] 2. To CdCu 3 Ti 4 o 12 Add 1.0% of its mass silica powder to the ceramic...

Embodiment 2

[0024] In this example, to CdCu 3 Ti 4 o 12 2.0% by mass of silicon dioxide powder was added to the ceramic powder, and the other steps were the same as in Example 1 to obtain a silicon dioxide-doped copper cadmium titanate giant dielectric ceramic material with high breakdown field strength and energy storage density.

Embodiment 3

[0026] In this example, to CdCu 3 Ti 4 o 12 4.0% by mass of silicon dioxide powder was added to the ceramic powder, and the other steps were the same as in Example 1 to obtain a silicon dioxide-doped copper cadmium titanate giant dielectric ceramic material with high breakdown field strength and energy storage density.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com