Ground anchor device suitable for saturated sandy soil site

A ground anchor and site technology, applied in construction, sheet pile wall, foundation structure engineering, etc., can solve the problems of liquefaction, insufficient uplift resistance, unable to solve the problem of soil liquefaction, etc., so as to reduce the loss of uplift force and ensure the uplift resistance. performance, the effect of improving the pullout resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

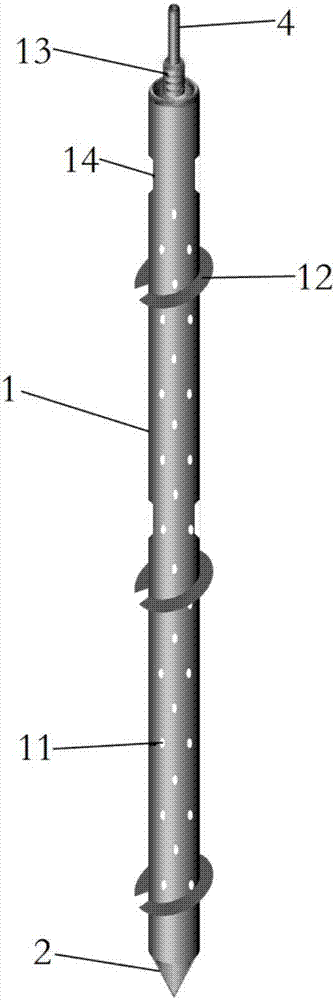

[0033] like figure 1 As shown, a ground anchor device suitable for saturated sandy soil sites includes a drill pipe 1 and a drill bit 2 . The main body of the drill pipe 1 is a hollow cylindrical tube, and a drill bit 2 is installed at the bottom end.

[0034] A plurality of water permeable holes 11 are evenly arranged on the outer wall of the drill pipe 1, and the excess pore water caused by the disturbance during the drilling of the drill pipe 1 into the saturated sandy soil can penetrate into the drill pipe 1 through the water permeable holes 11, so as to accelerate the vibration of the drill pipe 1 in the process of entering the soil The resulting excess pore water pressure dissipates, reducing the possibility of liquefaction, thereby ensuring the pullout resistance of the ground anchor drill pipe.

[0035] There are three-stage threaded disks 12 on the outer wall of the drill pipe 1. The diameter of the threaded disks 12 increases step by step along the drill pipe 1. Thi...

Embodiment 2

[0038] In this embodiment, on the basis of the above embodiments, the drill pipe 1 has a length of 150 cm and an outer diameter of 3.4 cm. The water permeable holes 11 are arranged in a rhombus or quincunx shape, with a hole spacing of 2-6 cm and a hole diameter of 0.1-0.2 cm. The location and diameter of the permeable holes 11 are calculated to ensure that the excess pore water enters the drill pipe 1 and reduce the possibility of liquefaction.

[0039] The disc diameter of the threaded disk 12 is 6-10 cm, and the single large-diameter threaded disk of the traditional ground anchor is replaced by the multi-stage small-diameter threaded disk 12, which can minimize the drill pipe 1 during the process of entering the soil. 1 The range of disturbed soil around.

[0040] The outer wall of the drill pipe 1 is provided with multi-stage rotating clamping grooves 14, and the distance between the rotating clamping grooves 14 of each stage is the same, and the position of the rotating ...

Embodiment 3

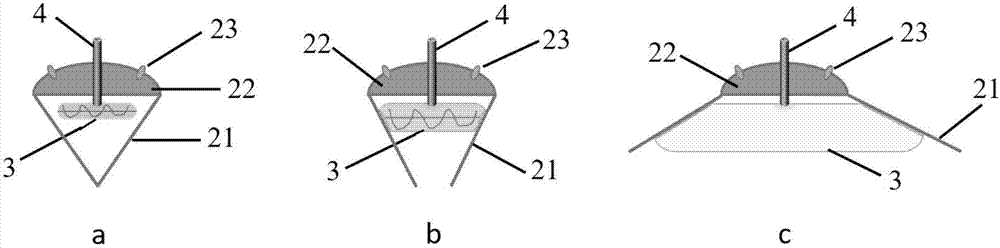

[0042] This embodiment is based on the foregoing embodiments, such as figure 2 As shown, the drill bit 2 includes a base 22 and a plurality of flaps 21 . The valve 21 is connected with the base 22 through a rotating shaft, and a torsion spring is installed in the rotating shaft, the valve 21 can be opened under force, and after the external force is removed, the valve 21 is closed under the spring force. The base 22 of the drill bit 2 is provided with a shaft lock 23 for controlling the opening angle of the valve 21 , and the position of the valve 21 is limited by the shaft lock 23 when the valve 21 is opened to a maximum angle. A water injection film bag 3 is installed in the cavity formed between each valve 21, and the water injection film bag 3 is connected with the water injection pipe 4 penetrating through the drill pipe 1. The water injection film bag 3 is ellipsoidal, and its horizontal length is much larger than the vertical length. Swells when water is injected.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com