Grouting-free soil nailing device suitable for temporary support of side slope and construction method of grouting-free soil nailing device

A temporary support and side slope technology, applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve the problems of increasing construction speed and saving engineering cost, low friction between surrounding soil bodies, complex procedures, etc., and achieves an improvement Pull-out bearing capacity, ensure pull-out performance, save the effect of complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

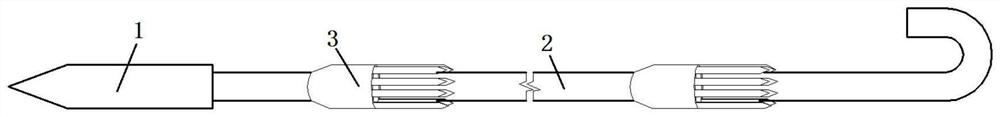

[0035] This embodiment discloses a grouting-free soil nailing device suitable for temporary support of slopes, which includes a reinforced rod cone 1 , threaded steel bars 2 and rubber limit clamps 3 .

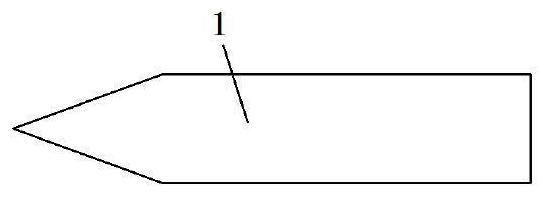

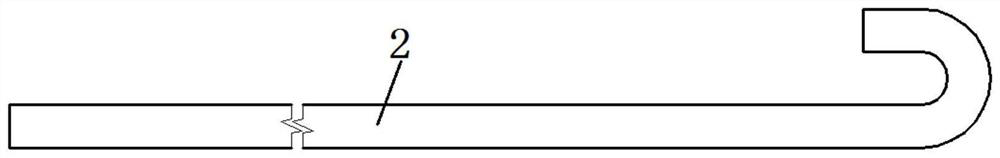

[0036] see figure 1 , 2 Or 3, one end of the reinforced rod cone 1 is conical, the other end has a smooth end surface and is welded to one end of the threaded steel bar 2, and the end of the threaded steel bar 2 away from the reinforced rod cone 1 is a hook structure , the bending angle of the hook structure on the rebar 2 is 180°.

[0037] The reinforced rod cone 1 can be processed from light round steel bars. The reinforced rod cone 1 includes a connected conical section and a cylindrical section. The end face of the cylindrical section away from the conical section is connected to the threaded steel bar 2. The cylindrical section The diameter is 4mm larger than the diameter of the threaded steel bar 2.

[0038] see Figure 4 , the rubber limit fixture 3 includes a main ...

Embodiment 2

[0044] see Figure 5 , this embodiment discloses a construction method based on a grouting-free soil nailing device suitable for temporary slope support described in Embodiment 1, comprising the following steps:

[0045]1) Make several reinforced rod cones 1, several threaded steel bars 2 and some rubber limit clamps 3; wherein, the reinforced rod cones 1 are cut and polished for smooth round steel bars to form one end It is a cone head, and the other end is a rod-shaped part with a flat cross section; when making the threaded steel bar 2, according to the design requirements of the pre-reinforced slope, intercept the threaded steel bar of the corresponding length, cut one end flat, and bend the other end Make the crotch of 180 degrees; When making described rubber limit fixture 3, hard rubber tube is cut into the section length of 20cm, and one end is cut into inclined-plane along the tube length direction, is convenient when being pressed into soil body, Reduce the resistan...

Embodiment 3

[0055] This embodiment discloses a grouting-free soil nailing device suitable for temporary support of slopes, which includes a reinforced rod cone 1 , threaded steel bars 2 and rubber limit clamps 3 .

[0056] see figure 1 , 2 Or 3, one end of the reinforced rod cone 1 is conical, and the other end is connected to one end of the threaded steel bar 2, and the end of the threaded steel bar 2 away from the reinforced rod cone 1 is a hook structure.

[0057] see Figure 4 , the rubber limit clamp 3 includes a main body 301, a closing mouth 302 and a number of thorns 303 all made of rubber materials, the main body 301 is a cylindrical structure, one end of the main body 301 is connected with a conical closing mouth 302, and the other end is connected There are several spines 303 arranged at equal intervals along the circumference of the main body 301 . Figure 4 middle, Figure 4 a represents the natural state of some of the spines 303, Figure 4 b represents a state in which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com