Split type equal-strength beam optical fiber grating acceleration sensor

A technology of acceleration sensor and equal-strength beam, which is applied in the direction of acceleration measurement, instrument, and measuring device using inertial force, which can solve the problems of adverse effects on measurement results, poor torsion resistance, and large lateral effect, etc., and achieve improved sensitivity and increased Sensitivity, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

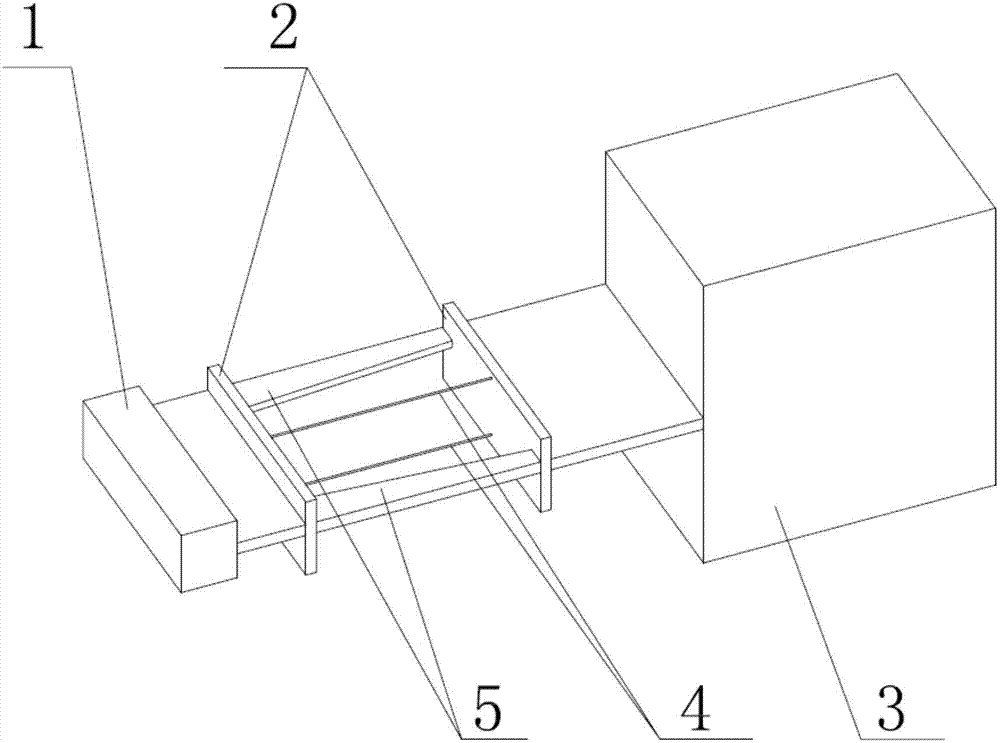

[0025] like figure 1 As shown, the split-type equal-intensity beam fiber grating acceleration sensor of the present invention includes a base 1, a sensitization part 2, a mass 3, a fiber grating 4 and a split-type equal-intensity beam 5, and the sensitization part 2 includes two Two sensitizing plates parallel in vertical direction, the two sensitizing plates include sensitizing plate I and sensitizing plate II, the sensitizing plate I is fixedly connected to the mass block 3, and the sensitizing plate II is fixedly connected to the base 1. The split equal strength beam 5 is arranged between the two sensitizing plates, one end of the split equal strength beam 5 is fixedly connected to the sensitizing plate I, and the other end of the split equal strength beam 5 is fixedly connected to the sensitizing plate II .

[0026] The equal-strength beam in the present invention divides the existing single equal-strength beam into two symmetrical beams of the same size along the center ...

Embodiment 2

[0038] The difference from Embodiment 1 is that a fiber grating is fixedly arranged between the two sensitization plates, and the fiber grating is located at the upper end or the lower end of the sensitization plate.

[0039] Others are with embodiment 1.

Embodiment 3

[0041] The difference from Example 1 is that the upper surfaces of the two sensitizing plates are located above the upper surfaces of the split equal-strength beams, and the lower surfaces of the two sensitizing plates are flush with the lower surfaces of the split equal-strength beams. A fiber grating is fixedly arranged between the two sensitization plates, and the fiber grating is located at the upper end of the sensitization plate.

[0042] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com