A Nonlinear Strength Analysis Method for Rear Axle System

An analysis method and non-linear technology, applied in the field of automotive CAE analysis, can solve the problems of fitting curve and original data error, large error, error size and position are not easy to calculate, etc., to achieve the effect of ensuring error accuracy and compressing data volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

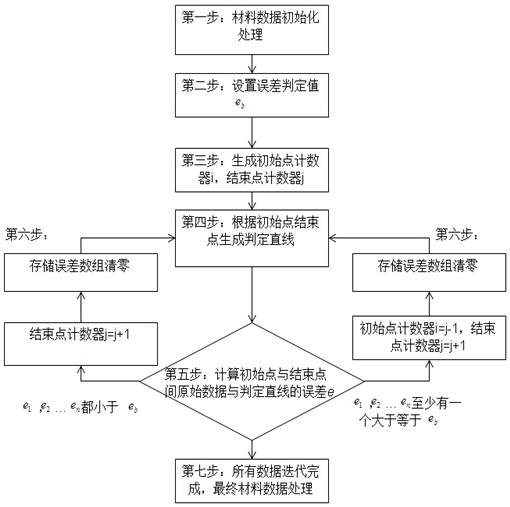

[0021] Further illustrate technical realization of the present invention below in conjunction with accompanying drawing:

[0022] see figure 1 , the logical steps of the nonlinear strength analysis method for the rear axle system are as follows

[0023] The first step is to process the measured material curve of the rear axle, and delete the points whose values on the vertical axis decrease. If there are multiple points with the same abscissa value, only the point with the highest value on the vertical axis is retained.

[0024] The second step is to set the error judgment value e according to the accuracy requirements of the material curve data b , according to experience, choose 1-5Mpa.

[0025] In the third step, an initial point counter i=1 and an end point counter j=3 are generated.

[0026] The fourth step is to connect the initial point and the end point to generate a judgment line.

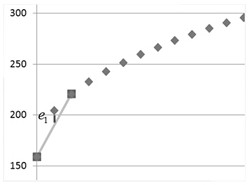

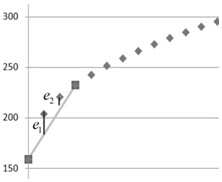

[0027] The fifth step is to calculate the error e between the original data and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com